IPA Tools 7864 Grease Joint Rejuvenator Pocket Model User Manual

Instructions, Grease joint rejuvenator, Professional model

GREASE JOINT REJUVENATOR

®

#7862, #7863 or #7864

INSTRUCTIONS

The Grease Joint Rejuvenator® allows a clogged grease

fitting or joint to take on fresh grease by injecting light

penetrating oil into the grease joint via the grease fitting,

thus breaking up and removing any dirt, rust or debris. The

purpose of this tool is to free up the joint and fitting, enabling

them to be greased.

SET UP: First remove the piston from the tool body and fill

with non-aerosol, penetrating oil. Once the tool body has

been filled, reinsert the piston, gently working it into the core

of the body. Be sure to clean the piston and O-Ring before

inserting, as dirt makes the tool less effective. NOTE: A spare

O-Ring is located near the head of piston shaft and serves as

a marker to show when the tool body is empty. To get the

best use out of this tool, bleed all the air out of it. When the

piston is inserted into the tool body, air may get trapped

inside. Any air left in the tool reduces the hydraulic pressure

causing the tool to be less effective. (If the piston bounces

back when tapped, it has air in it!)

REMOVE THE AIR: After filling the tool body with light oil,

put the piston back and turn the tool upside down to allow

the air bubble to float to the top. Place a rag over the end of

the tool and tap on the piston lightly with your hand until the

air bubble burps out. You are now ready to use the tool.

When bleeding, be sure and keep your face and eyes away

from expelling air and fluid. (WEAR SAFETY GLASSES!)

USING THE TOOL: Once the air has been bleed from the tool,

you are now ready to unclog a stuck fitting or joint. If using

the Professional Model, push the Grease Coupler over the

grease fitting and tap the piston head with a light hammer. It

may take several taps, but the piston will eventually move

down into the tool body. This is the indication that the joint

is being opened. Once the piston has pushed all the oil out,

remove the tool and grease the joint. (Note: some joints are

more stubborn than others. Several attempts with the

Grease Joint Rejuvenator® may be necessary.) If using the

Pocket model, gently place the open end over the grease

fitting and hold the tool down firmly. (The O-ring inside the

end of the tool creates a seal and keeps the oil from leaking

out.)

PRECAUTIONS: Be sure NOT to hit the tool too hard as you can

snap off a grease fitting or damage the tool. If you find a

stubborn fitting, try loosening the grease fitting one or two turns

to expel any trapped air and increase the cleaning pressure.

When the Grease Fitting Coupler on the end of the Professional

Model is new, it may be difficult to remove from a fitting.

Unscrew the head a quarter turn to loosen the jaws holding the

fitting. The jaws can be turned around for extra life. (Note: The

jaws are a wearable item and are not warranted.)

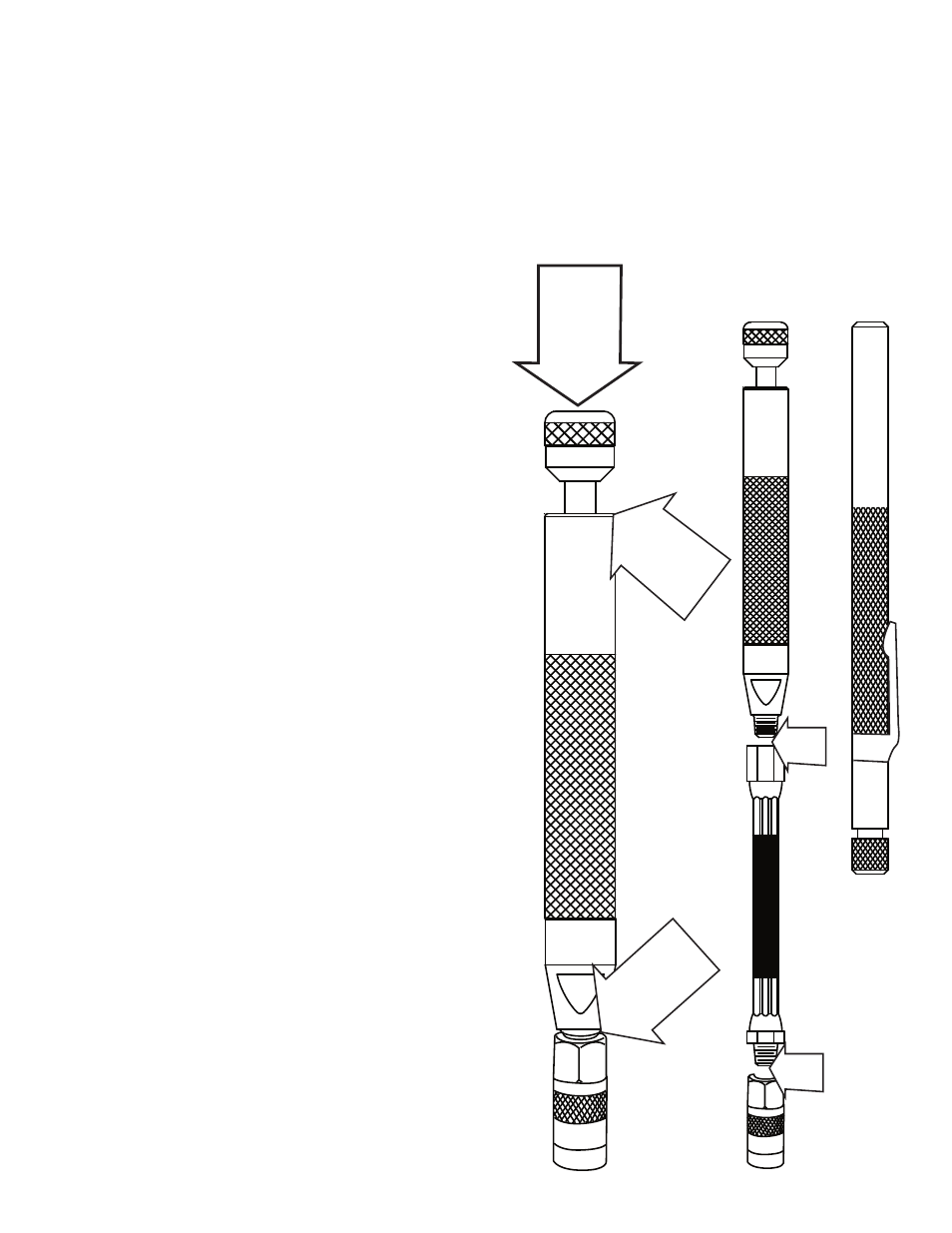

INSTALL AUXILIARY FLEX HOSE: Some applications may

require the use of the auxiliary hose to make a bend. To

install the flex hose, remove the female grease fitting coupler

from the Professional Model #7862. Use sealant tape and

install the flex hose into the tool body, then install the grease

coupler on the end of the hose. This gives you flexibility when

007862-7863-7864 IPA Instructions

WARRANTY: Contact your distributor for warranty

claims and concerns.

PROFESSIONAL MODEL

PATENT

PENDING

ATTACH

HERE

ATTACH

HERE

COUPLER

PIST

ON

HEAD

PATENT

PENDING

TAP

HERE

GENTLY

AFTER

FILLING

COUPLER

FLEXIBLE EX

TENSION

TOOL BODY

REMOVE

PIST

ON & ADD

PENETRA

TING

OIL HERE

SEP

ARA

TE HERE

ONL

Y WHEN

AT

TA

CHING

EX

TENSION

MODEL

trying to access tight places. The use of the hose should only

be temporary. The Grease Joint Rejuvenator® works best

without the hose. (Auxiliary hose can only be used with the

Professional Model.)

CLEANING: Keep unit dry and oiled. If unit rusts, use a light

steel wool and oil as soon as possible.