Critical points for a proper lpv gas installation – Gillette Generators SP-1500 User Manual

Page 22

PAGE 22

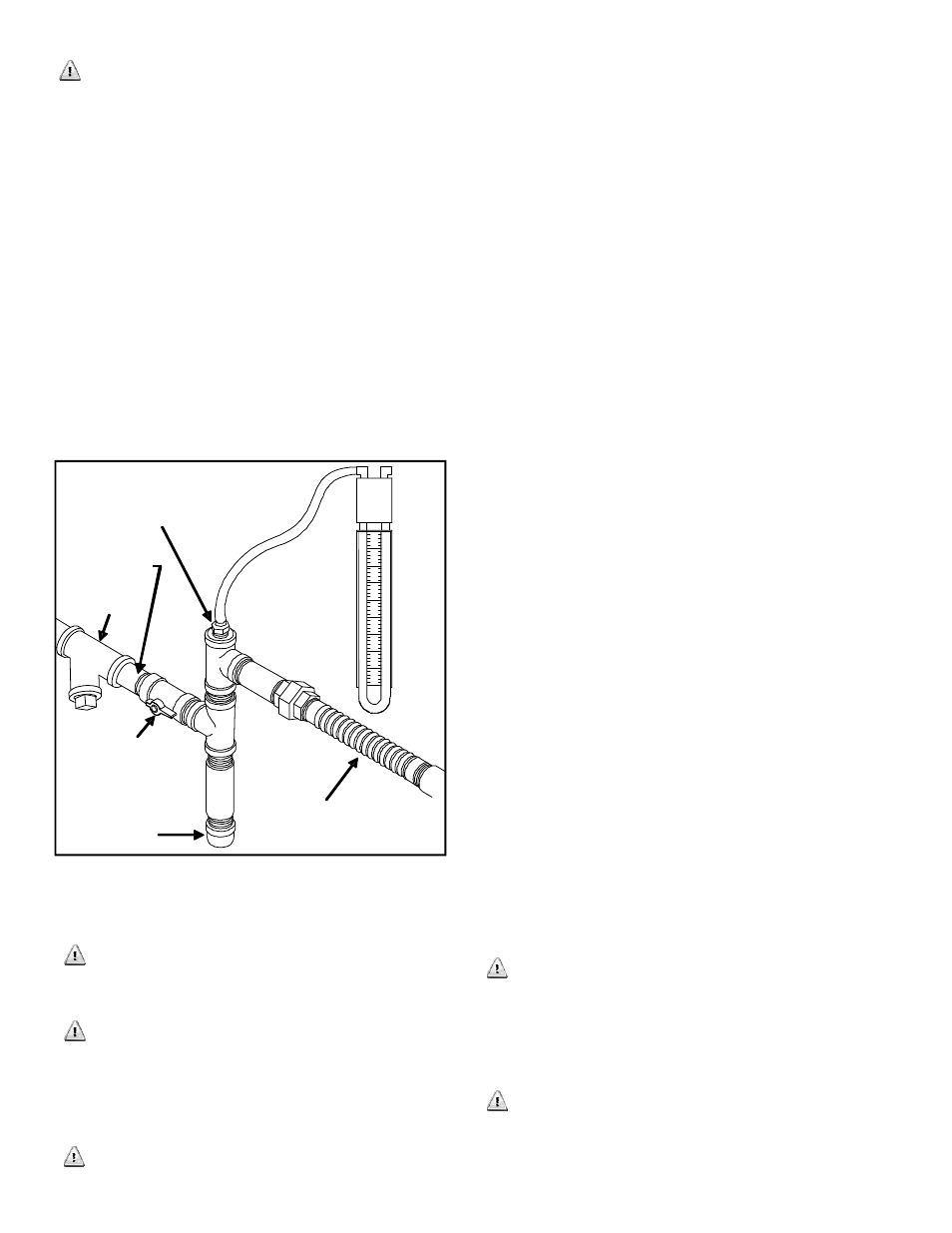

All new installations, plus any future repair or

troubleshooting procedures must include a natural

gas manometer test. This test should be conducted

after all other natural gas appliances have been

turned on. After all appliances are running, start

the generator. If manometer stays within 7 inches

water column with full load applied to a proper

running generator, it’s a good installation. (See

Figure 10)

If manometer reading falls below 7 inches water

column while generator engine is cranking, or

running, it may indicate the gas meter or primary

regulator is too small, or the fuel pressure from gas

supplier is inadequate. Any of these three problems

will cause a fault in proper generator operation.

If manometer reading stays within the 7 inches water

column, but generator engine still will not start, or it

runs erratic, it may indicate insufficient fuel volume

due to long fuel line runs or fuel pipe diameter is too

small. Check calculations of charts on page 20.

NOTE: After completion of all gas tests, remove

manometer and replace blank plug, using fresh pipe

sealant.

For additional precautions, a manual fuel shut-off

valve should also be installed inside the building, for

those locations with inside gas meters.

Climates that have snow and ice build-up, along

with sub-zero temperatures, should have gas fuel

piping protection against freezing. The generator

end of the hard piping installation should include a

sediment trap to drain any condensation, and a line

filter. (See Figure 10)

Best installations happen when electric utility

meter and gas meter are close together, as it results

in short runs for both electric wires and fuel lines.

When these two utilities are far apart, always choose

to locate gen-set close to the gas meter, as installation

costs are lower when increased electrical wire size

must be used for the long runs rather than increased

fuel pipe diameters.

CRITICAL POINTS FOR A PROPER LPV,

VAPOR WITHDRAWAL INSTALLATION

This generator system has been set up at the factory

for natural gas fuel, unless it has been specifically

ordered for vapor withdrawal liquid propane gas

(LPV). This installation/operation guide will explain

the factory LPV system. Additional information is

available upon request for field conversion from one

fuel to the other.

LPV fuel is typically at farms or remote areas where

there is no natural gas fuel.

LPV must be a vapor withdrawal system (the

generator will not work on liquid withdrawal

systems). Proper LPV is clean and free of moisture or

particulate matter. It consists of a propane HD5 grade

with minimum 2500 BTU’s per cubic foot energy

rating. A typical blend is 5% propylene and butane

plus a minimum 90% propane.

Required LPV vapor withdrawal fuel pressure is 11

-14 inches water column at (6-6½ ounces) 2500

BTU’s per cubic feet.

CAUTION: It is critically important to understand,

that as a specific fuel line pipe diameter is extended

in length, its ability to carry the volume of gas,

diminishes in direct proportion.

INSTALLER’S RESPONSIBILITY: Use chart (Table

A) on page 20 to learn fuel cubic feet/hour value of

generator to be installed. Use LPV fuel chart

(Table B) to learn minimum pipe size diameter

and maximum distance from LPV tank to insure

sufficient fuel volume from LPV tank to generator.

CRITICAL POINTS FOR A PROPER LPV

GAS INSTALLATION

Before LPV fuel line plans are made, call your

LPV supplier, give information on the amount of cubic

feet/hour and BTU’s/hour from tables on page 20, that

your generator will use, and ask about local codes

and regulations concerning LPV fuel connected to

generators.

Only LPV vapor withdrawal (not LPG liquid

withdrawal) will work on these generators. Make

sure the LPV tank has the correct fuel, and volume

capacity.

Manometer Port: Remove

Blank Plug And Insert

Manometer Plug

Dedicated Natural

Gas Fuel Line From

Natural Gas Meter

Line Filter

Manometer

Reading

Must Be

7” Water

Column

On/Off Valve

Sediment Trap

Flexible Stainless

Steel Gas Pipe

(without bends

or angles)

Gas Fuel To

Generator

Figure 10 NATURAL GAS LINE