Danger, Warning – Gillette Generators SP-1500 User Manual

Page 19

PAGE 19

1) “Standard” housing with standard interior sound

deadening foam and mounted residential grade

muffler.

2) “Super-Silent” housing with special interior foam

having damping material included.

3) “Super-Silent” housing also has a “Critical” grade

muffler included with a choice of “Hospital” grade

muffler as an additional upgrade.

4) “Super-Silent” housing also has an additional air

chute (much like the engine end air chute) for

increased generator end silencing.

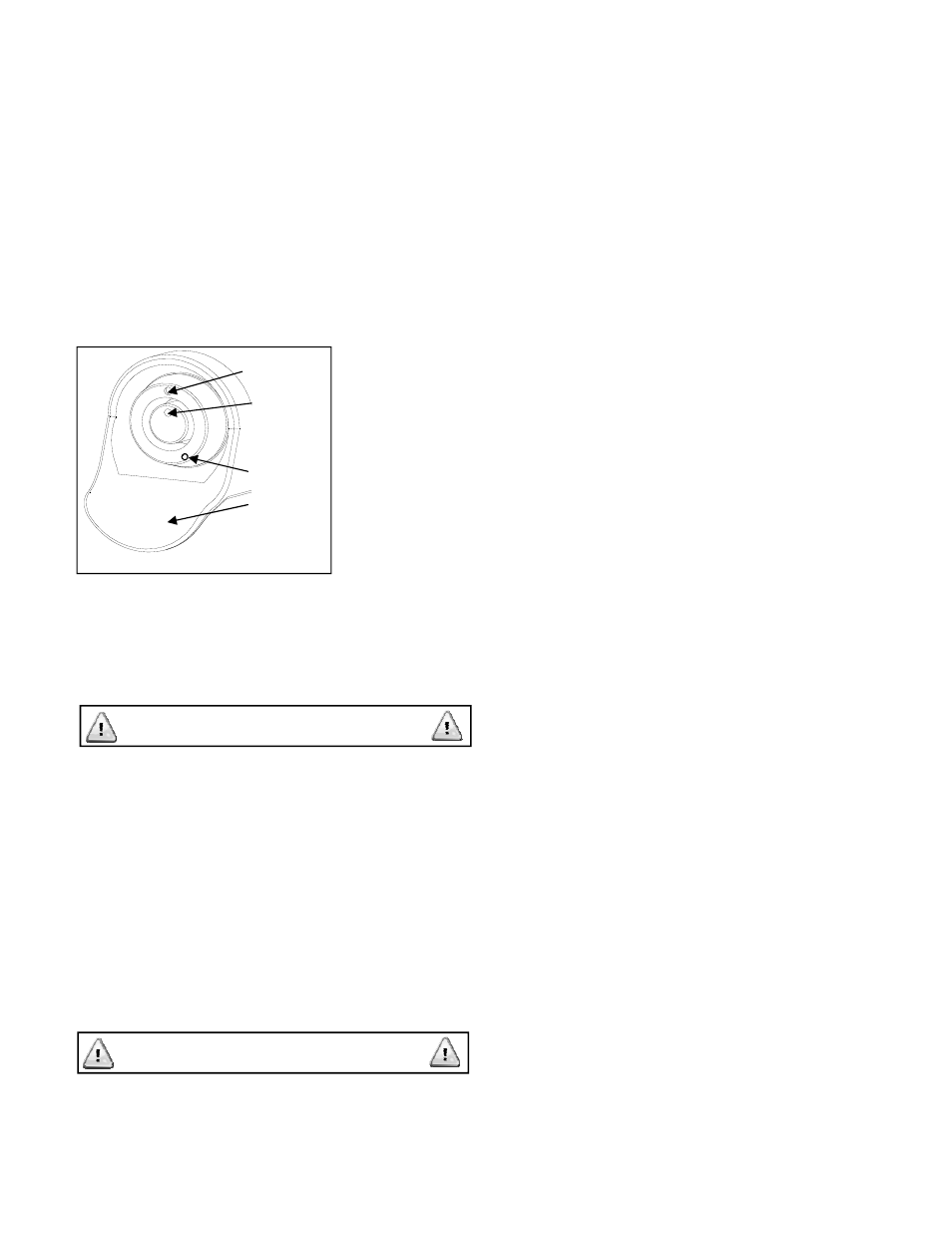

All generator

access doors are

locked, and are

opened with a

common key for

all locks. Notice

the door lock (in

t h e l o c k e d

position) has

matching dot

s y s t e m i n

alignment. Insert

the key into lock

and turn counterclockwise. Remove the key and

note, the dots are now out of alignment. Re-insert the

key, turn clockwise until dots align, and it’s in the

locked position. All doors are hinged, and once

unlocked, will swing open. All keys are universal,

used on all housing sizes.

All doors have grounding wire, connecting and

grounding door to housing frame. DO NOT

REMOVE these grounding wires. If it becomes

necessary to remove and replace door, be sure to

replace grounding wire and to reuse self grounding

star washers, to prevent accidental electrical shock,

if live circuit wires were to touch housing parts.

EXHAUST SYSTEM

The engine end of housed gen-set will have hot

exhaust air discharge from engine muffler, mounted

within housing for complete generator hot air

discharge.

Even though the muffler is safely concealed within

hot air engine exhaust chute, the muffler exhaust

pipe and its accompanying rain cap, extending

straight up from roof, will cause severe burn to the

DANGER

WARNING

touch. This “Hot Pipe Burn” warning remains in

effect for 60 minutes after shut-down of generator set.

CORROSION TO GENERATOR AND

HOUSING

Depending on the area of generator installation, will

depend on the amount of attention given to gen-set

cleanliness. Heavy concentration of salt water

exposure (USA Coastal Regions, and Tropics), will

require frequent washings and a final waxing of

generator housing, much like an automobile’s

special care in these areas. Salt corrosion may enter

the generator interior, which may have to be

removed by special detergents. Every 3 months,

spray the engine governor linkage, springs, and

other engine control moving parts with a light spray

coverage of WD-40 to help prevent or prolong

corrosion destruction.

In severe Coastal or Tropical conditions, it is advised

to use aluminum housings, as opposed to steel

housings.

DRY FUEL GAS PIPE SIZING

INFORMATION

Fuel line diameter depends on the amount of fuel

needed to run an engine-generator at full load and at

the distance the fuel must be moved. Refer to the fuel

specification sheet on page 20.

INSTRUCTIONS IN FINDING CORRECT PIPE

SIZES: Use engine HP or KW size of the gen-set to

find fuel consumption on either LPV or Natural Gas.

Then use this fuel consumption amount to match up

with the length of fuel pipe run, to determine pipe

diameter.

EXAMPLE 1: A 30 KW gen-set having 48 HP engine

with Natural Gas fuel is to be located 95 feet from

source of fuel. Locate fuel consumption in Table A for

42 HP = 539 cu. ft. for Natural Gas fuel. Locate closest

fuel consumption in Table C, to 539 cu. ft. under

Column 91-100 ft. run = 605 cu. ft. Locate the pipe

diameter for this amount of fuel, at left side of Table C

= 1½” Dia.

EXAMPLE 2: A 100 KW gen-set having a 162 HP

engine with LPV fuel is installed 125 ft. from LPV tank.

Locate fuel consumption in Table A for 100 KW, 162

HP = 595 cu. ft. In Table B, locate the closest cu. ft. to

595 under 116-125 pipe length, column = 679 cu. ft.

Locate pipe diameter for this amount of fuel at left

side of Table B = 1¾ diameter.

EXAMPLE 3: A 20 KW gen-set having a 42 HP

engine with Natural Gas fuel is installed 15 Ft. from

source of fuel. Locate fuel consumption in Table A for

20 KW, 42 HP = 387 Cu. Ft. for Natural Gas fuel. In

Table C, locate the closest fuel consumption to 387

ACCESS TO HOUSING INTERIOR

Stationary Dot

Dot-aligned,

Locked

Position

Un-Locked

Position

Raised

Finger

Hold

FIGURE 9