Mss series, General pump – General Pump MSS Owner Manual User Manual

Page 15

GENERAL PUMP

A member of the Interpump Group

MSS SERIES

Page 15

Screw calibration is to be carried out by

means of a torque wrench only:

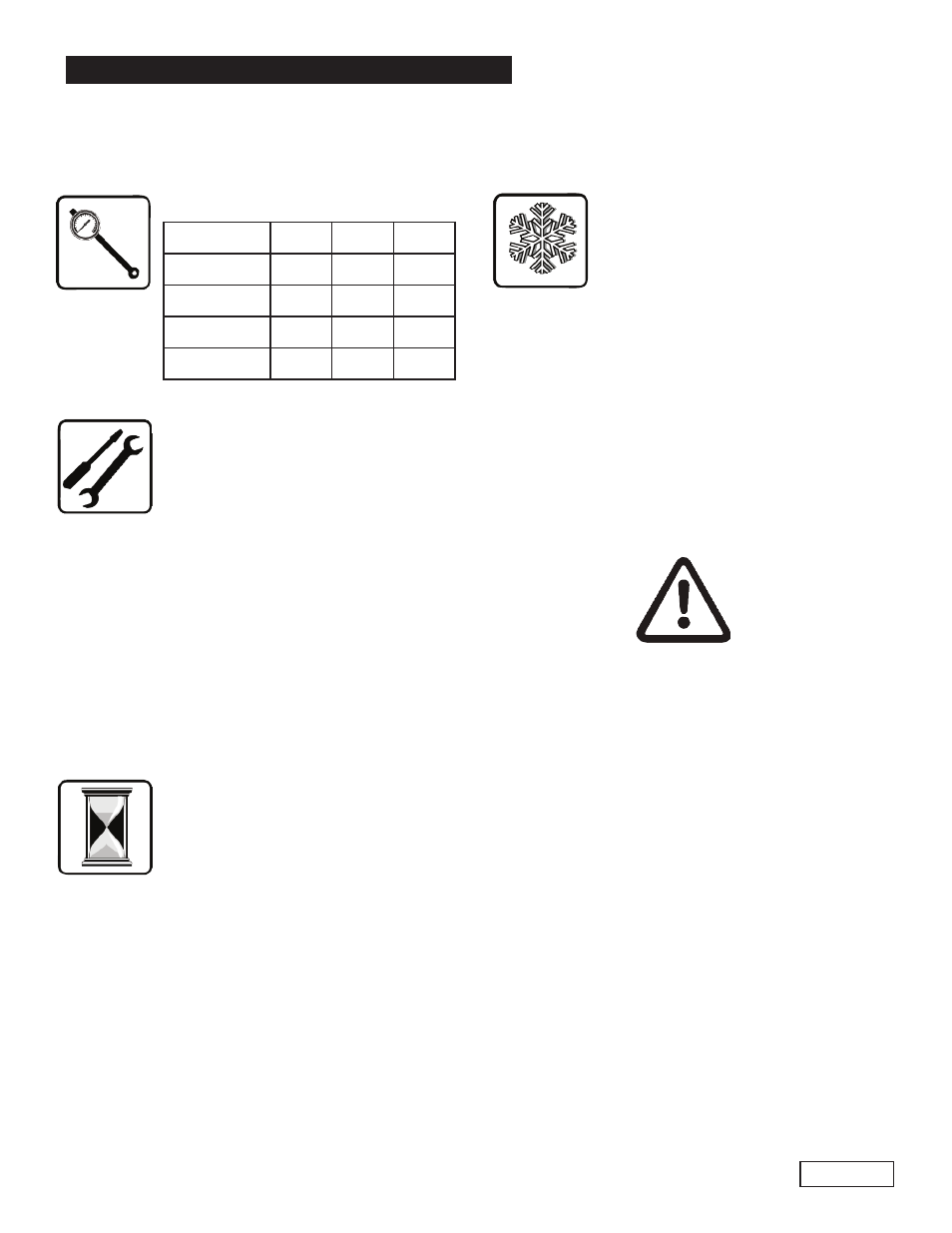

12. SCREW CALIBRATION

13. MAINTENANCE TOOLS

The following tools are designed to

facilitate mounting and dismounting

operations of some pump components:

for disassembling:

-Packing support extractor

F200030050

-Main gear (gear box)

F200030020

- Valve extractor

F200000050

14. PUMP STOPPED FOR LONG TIME

Before starting the pump for the very first

time after a long period from the date of

shipment check for the correct oil level,

check the valves as indicated in chapter

11 and then comply with the starting

procedures indicated in chapter 10. When

a long inactivity is scheduled drain the

entire suction and delivery line and then

run the pump dry only for a few seconds

in order to drain out the water collected

inside the fluid end.

15. PRECAUTIONS AGAINST FREEZING

In the risk of freezing the following

precautions should be taken:

-

After use drain the entire suction and delivery lines

(filter included) by means of discharging devices,

provided and positioned specifically for this purpose

along the lowest point of the lines.

-

Run the pump only for a few seconds in order to

drain the water collected inside the fluid end.

Or when applicable

-

Add a recommended amount of anti-freeze into the

water tank and run the pump until the anti-freeze

works all through the system.

If a pump is frozen or appears frozen ON NO ACCOUNT

SHOULD THE PUMP BE OPERATED until the entire

system has been thawed out.

DESCRIPTION

Ft. Lbs.

N-m

Kgm.

Valve cover

screws

86.7

117.6

12

Head Bolts

180.8

245.1

25

Plunger bolts

72.3

98

10

Connecting Rod

Screws

54.2

73.5

7.5

Ref 300522 Rev.D

01-13