Mss series, General pump – General Pump MSS Owner Manual User Manual

Page 13

GENERAL PUMP

A member of the Interpump Group

MSS SERIES

Page 13

11.3 Pumping unit maintenance

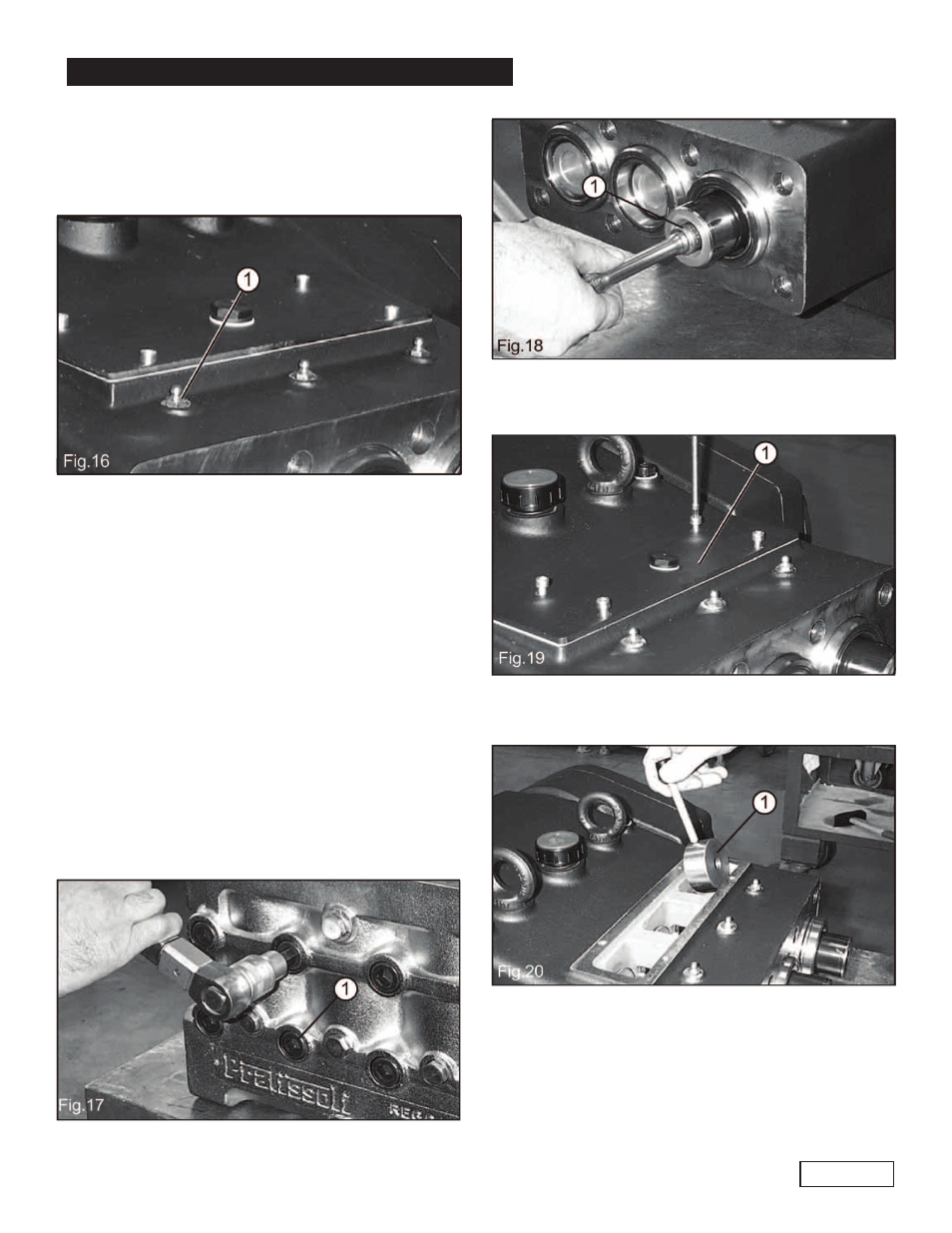

The only maintenance operation required for the pumping

unit is greasing the pressure packings through the proper

greasers (1, Fig. 16).

Greasing should be carried out at even intervals at

least every 100 hours by means of a hand pump. Stop

greasing when the pump trigger becomes harder to

operate: that means the grease chamber is full. Use

top quality silicone grease (i.e. DANKELL OCILIS 250,

penetration coefficient 290 or a corresponding one).

Periodically check the amount of water drained out

by the pump through the hole provided in the lower

cover (Fig. 6). It clearly shows the pressure packing

state of wear; replace them if water dripping becomes

continuous and not intermittent.

Loosen and remove the plunger screws (1, Fig. 18).

Remove the upper cover by loosening the four screws

(1, Fig. 19).

For inspecting the pumping unit remove the head by

loosening the eight head screws (1, Fig. 17).

Push the plungers forward by rotating the crankshaft,

then introduce our tool p/n F200030050 (or equivalent)

in between the piston guide and the packing support

(1, Fig. 20).

Ref 300522 Rev.D

01-13