Mss series, General pump – General Pump MSS Owner Manual User Manual

Page 14

GENERAL PUMP

A member of the Interpump Group

MSS SERIES

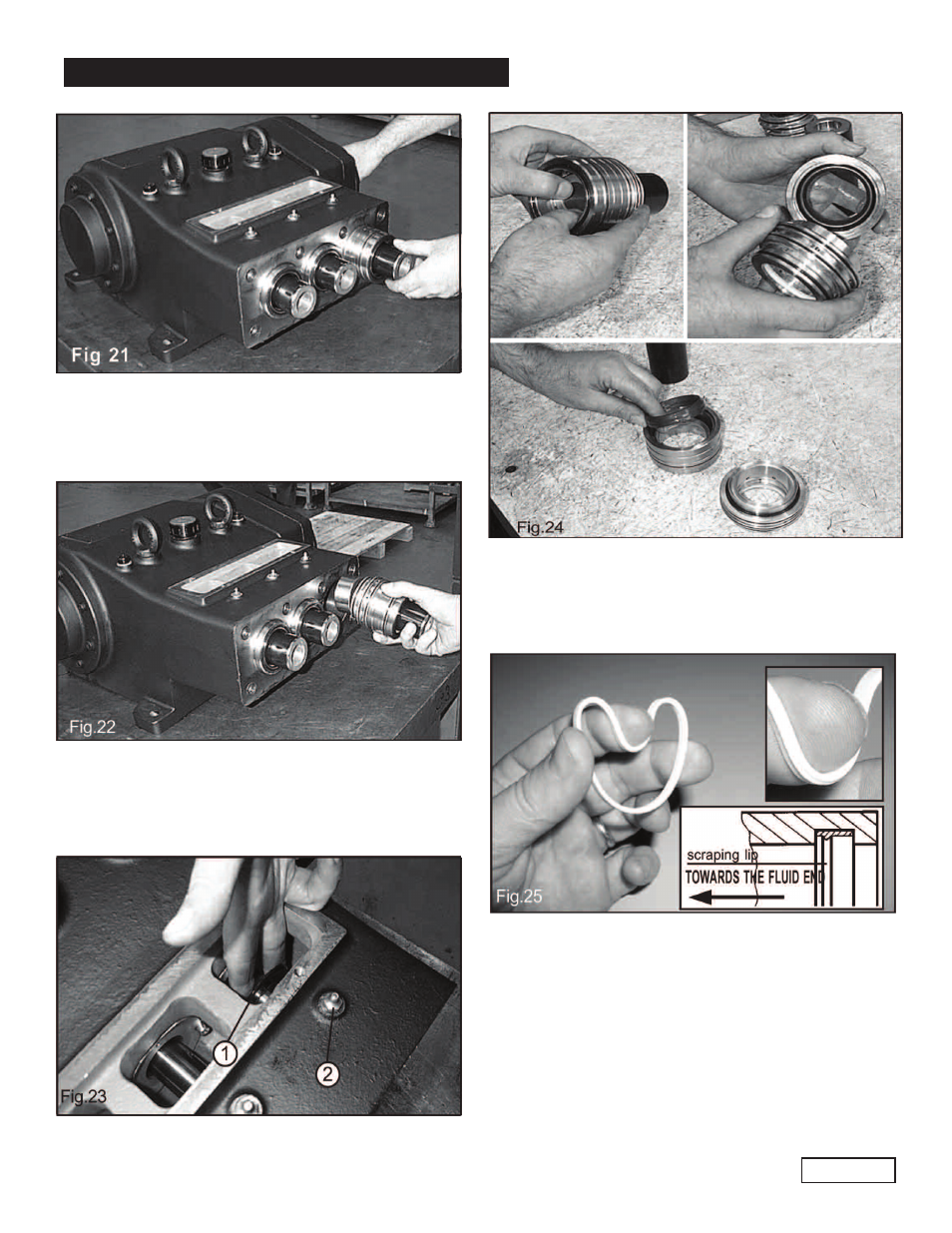

With the tool in place, rotate the crankshaft until the

packing support is pushed out together with plungers and

cylinders (Fig. 21 and Fig. 22).

Repeat the operation for each pumping unit.

Remove the wipers from the plunger guides (1, Fig. 23).

In order to fit the new scraper in place shape it manually

as shown in Fig. 25. VERY IMPORTANT! The scraper is

provided with an internal lip which performs the correct

scraping effect only if oriented towards the fluid end. See

window inside Fig. 25. Put the pumping unit components

together and fit them back in the pump crankcase. Tighten

the plunger screws (1, Fig. 18) with a torque

wrench set for 72.3 ft. lbs. Grease the pressure packings

through the greasers (2, Fig 23) by means of a hand

pump. Stop greasing when the pump trigger becomes

hard to operate: that means the grease chamber is full.

Put head back in place , with head screws tightened at

180.8 ft. lbs.

Separate the pumping unit components and check them

for wear. Pressure packing replacement is carried out

by hand without need for special tools (Fig. 24). A little

bit of grease helps slide the packings into the packing

support. Pressure Packings and o-rings should always be

replaced at every disassembling of the pumping unit.

Page 14

Ref 300522 Rev.D

01-13