Mks series, General pump – General Pump MKS Owner Manual User Manual

Page 14

GENERAL PUMP

A member of the Interpump Group

MKS SERIES

Page 14

10.2 Start-up

1. When starting the pump for the first time, check for

the correct direction of rotation.

2. The pump must be started off-load.

3. Verify correct feeding pressure.

4. During operation, check that the rotating speed does

not exceed the rated value.

5. Before putting the pump under pressure let it run for

at least 3 minutes.

6. Before stopping the pump, release the pressure by

acting on the adjustment valve or on any discharging

device.

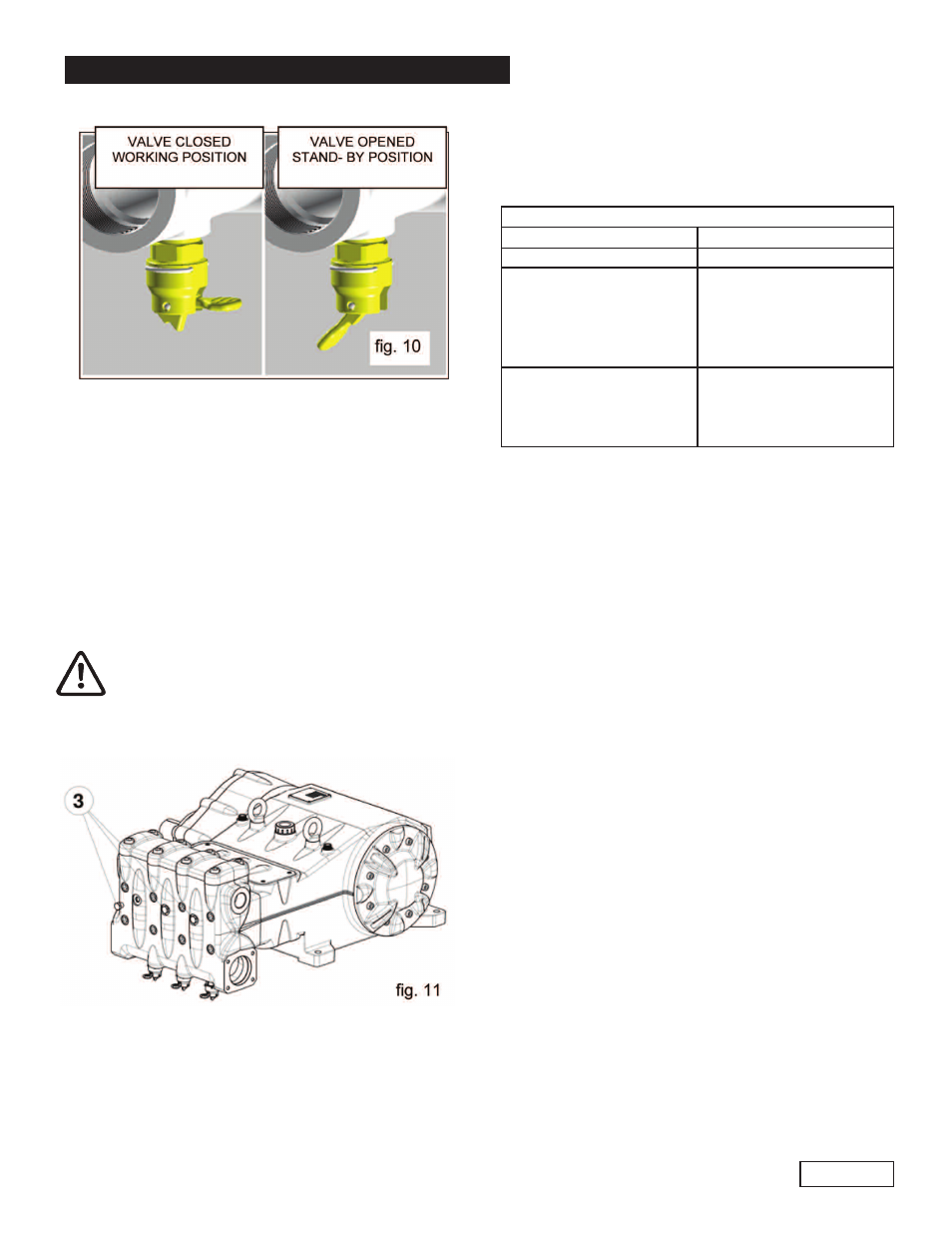

In case of priming problems caused by insuffi-

cient feeding, it’s possible to intervene by

removing the three front caps on the head (see

position 3, fig. 11).

11. PREVENTIVE MAINTENANCE

PREVENTIVE MAINTENANCE

EVERY 500 HOURS

EVERY 1500 HOURS

Check oil level

Change oil

Check / Replace:

• Valves

• Valve seats

• Valve springs

• Valve guides

Check / Replace:

• H.P packings

• L.P. packings

To guarantee pump reliability and efficiency, respect the

maintenance intervals as indicated in the table below.

12. STOPPING THE PUMP FOR LONG PERIODS

12.1 Filling the Pump With An Anti-Corrosion

Emulsion or Anit-freeze By Using An External

Diaphragm Pump As In The Layout Shown in

Paragraph 9.7.

a) Close the filter draining, if open.

b) Be sure that the connecting hose is clean, spread

with grease and connect it to the high pressure outlet

port.

c) Fit a suction hose to the membrane pump. Open the

pump suction connection and fit hose between it and

the membrane pump.

d) Fill the container with the solution/emulsion.

e) Put the free extremeties of the suction line and the

high pressure outlet hose inside the container.

f) Start up the diphragm pump.

g) Pump the emulsion until it comes out of the high

pressure hose.

h) Continue pumping for at least another minute; if

needed, the emulsion can be reinforced by adding,

for example, Shell Donax

i) Stop the pump, remove the hose from the suction

connection and close it with a plug.

j) Remove the hose from the high pressure outlet port.

Clean, grease and plug both connections and the

hoses.

12.2 Hoses

a) Before greasing and protecting the hoses according

to the previously described procedure, dry the con

nections using compressed air.

b) Cover with polyethelene.

c) Do not wrap them too tightly; be sure there is no

bending.

f

ig. 14

Ref 300670 Rev. B

05-13