Kl series, General pump – General Pump KL User Manual

Page 12

GENERAL PUMP

A member of the Interpump Group

KL SERIES

Page 12

11.3 Pumping unit maintenance

The only maintenance operation required for the pumping

unit is to periodically check the amount of water

drained out by the pump through the hole

provided in the lower cover (Fig 6, page 9).

It clearly shows the pressure packing state

of wear; replace them if water dripping

becomes continuous and not intermittent.

In order to check for the pumping units, separate the

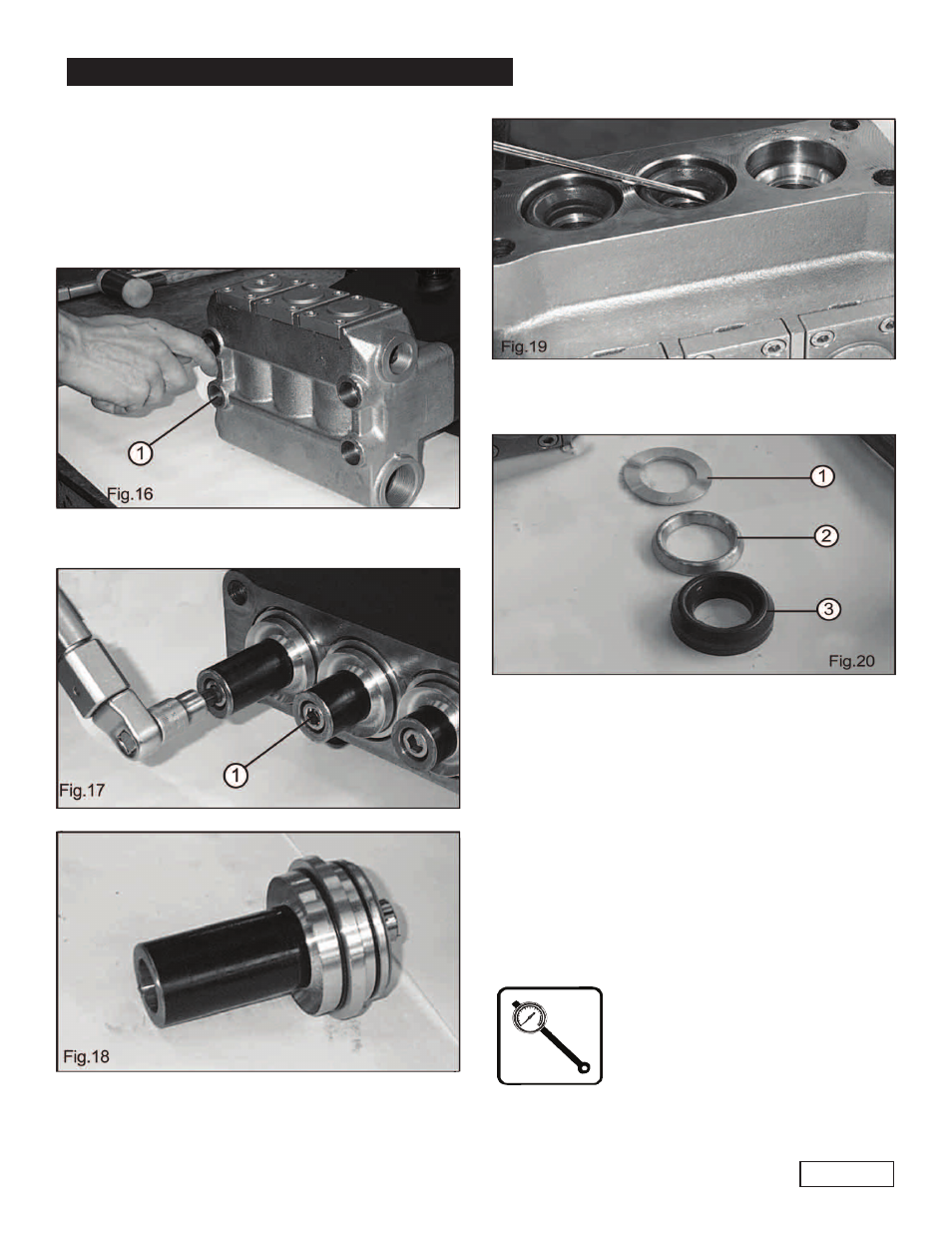

complete fluid end from the pump by removing the four

bolts (1, Fig. 16).

Remove the plunger screws (1, Fig. 17).

Once fluid end and plunger screws are removed,

cylinders and plungers are free to slide out without any

other operation (Fig. 18). Check the state of wear of the

parts and replace where necessary. Every o-ring should

be replaced at every inspection.

Replace pressure packings every time the fluid end

is disassembled. The operation can be carried out with

simple tools or by hand as well (Fig 19).

When reassembling make sure of the correct order of

the entire package made up of the following components

(Fig. 20):

1. Spacer

2. Packing ring

3. Pressure packing (two pieces)

A little bit of grease helps when sliding the pressure

packings into the fluid end. Fit the plunger back in place

without tightening the plunger screw. Fit the cylinder

back in place and then tighten the plunger screw with a

torque wrench set for 50.6 ft. lbs.

Fit the fluid end back in place and

tighten the four bolts (1, Fig 16) with a

torque wrench set for 133.8 ft. lbs.