Kl series, General pump – General Pump KL User Manual

Page 10

GENERAL PUMP

A member of the Interpump Group

KL SERIES

Page 10

11. MAINTENANCE INSTRUCTIONS

11.1 Crank mechanism maintenance.

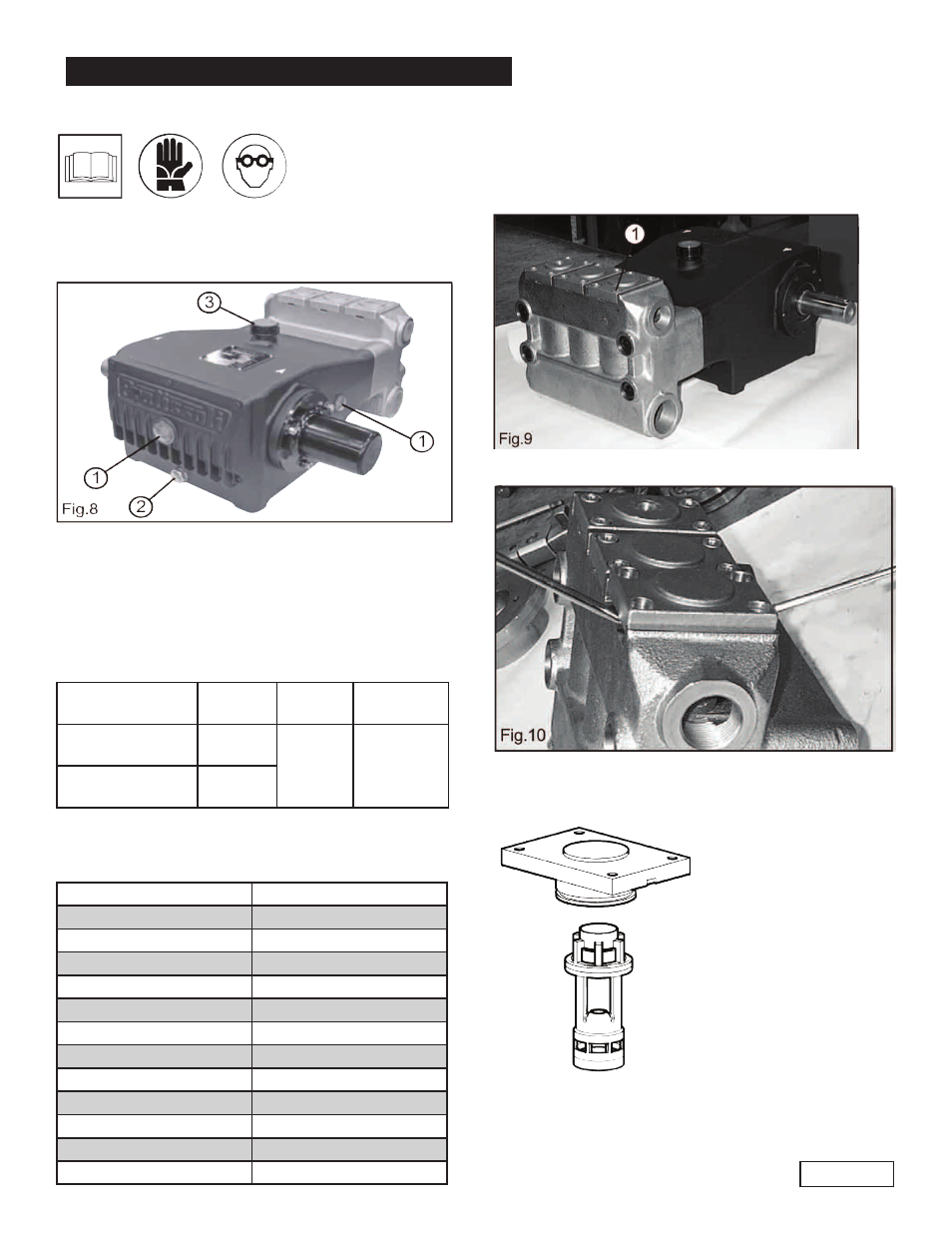

Check oil level through the oil level indicator 1, Fig 8 at

least on a weekly basis.

If necessary, top up from the oil plug 3, Fig. 8.

Check the oil when cold and change the oil when still

hot (pump still at working temperature.).

In order to drain the oil from the pump remove the

magnetic plug 2, Fig. 8.

At every oil change clean the magnetic plug 2, Fig. 8 and

check the lower cover of Fig. 6 for grease

sediments or deposits.

OIL CHANGES

Hours

Qty.

Oil

Type

First Change

50

3.1

quarts

ISO

220

Subsequent

Changes

500

BRAND

TYPE

AGIP

ACER 220

ARAL

MOTANOL HP 220

AVIA

AVILUB RSL 220

BP

ENERGOL HL 220

CASTROL

ALPHA ZN 220

ESSO

NUTO 220

FINA

SOLNA 220

IP

HYDRUS 220

MOBIL

DTE OIL BB

SHELL

TELLUS C 220

TEXACO

REGOL OIL 220

TOTAL

CORTIS 220

Oil should be changed at least once a year.

Recommended oils:

11.2 Fluid end maintenance

The fluid end does not require periodical maintenance.

Service operations are limited to valve inspection

and/or replacement, when necessary. In order to remove

the valves:

Loosen and remove the valve cover screws (Fig. 9).

In order to facilitate pulling the valves out, marked

marked notches in the valve cover are provided (Fig 10).

Valve components of each

valve unit are pressed

together in one single block

and therefore they can be

easily

replaced

and

installed back in place.

Separating the various

components of the valve

unit is carried out by

means of simple tools as

shown in Fig. 11, 12, 13 on

page 11).