Kez series, General pump – General Pump KEZ Owner Manual v.2 User Manual

Page 9

GENERAL PUMP

A member of the Interpump Group

KEZ SERIES

Page 9

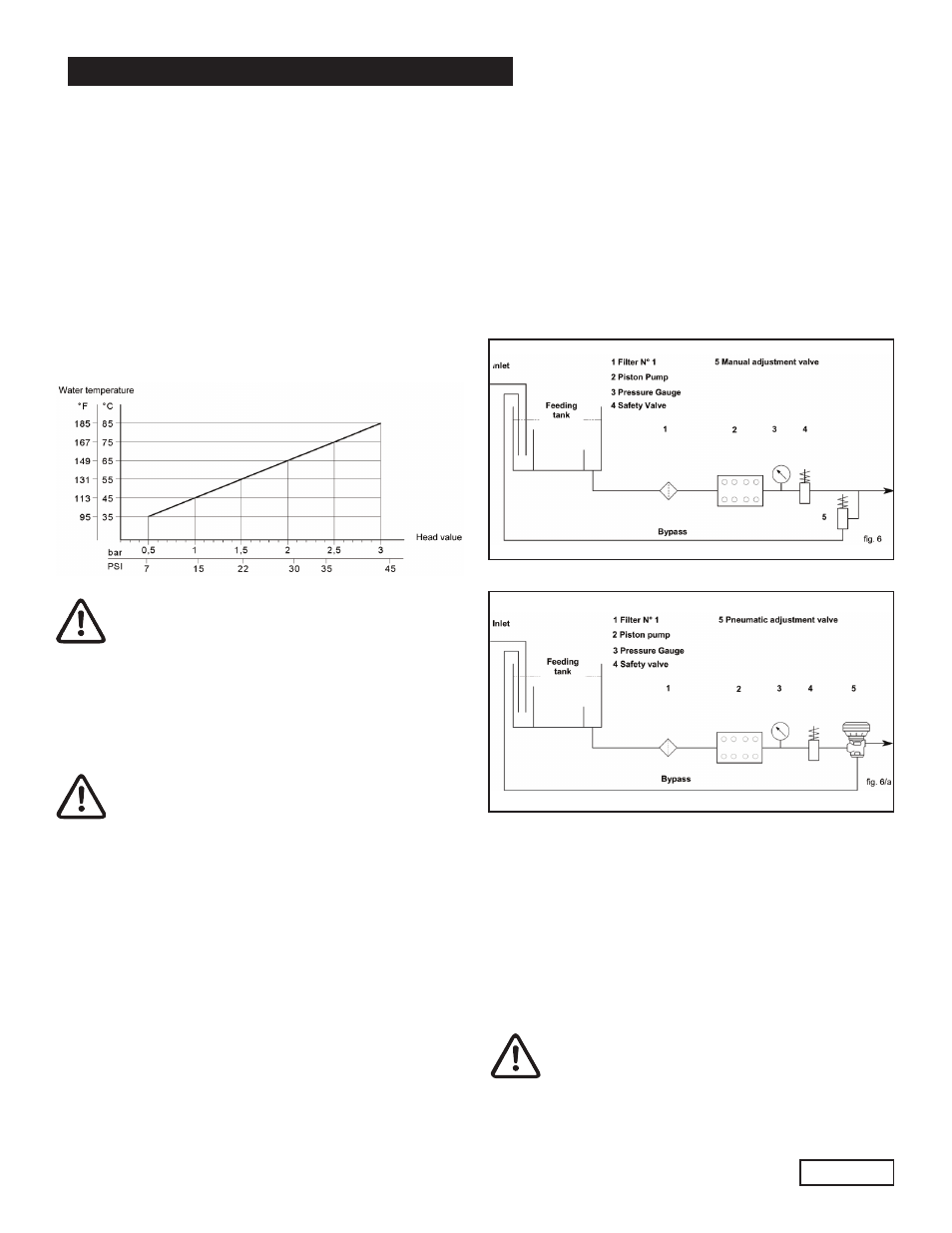

9.4 Hydraulic Connections

In order to isolate the system from the vibrations produced

by the pump, we advise to build the first section of the duct

near the pump (both for intake and delivery) with flexible

hose. The consistency of the intake section must allow to

avoid deformation caused by the depressurization pro-

duced by the pump.

9.5 Pump Feeding

To obtain the best volumetric efficiency, a minimum posi-

tive head of 0.20 meters (7.87 inches) is required. In case

of fluid temperatures ranging from 95

0

to 185

0

F (35

0

to

85

0

C) the correct inlet pressures are specified in the

graph below.

For negative head values, please contact the

Customer Service Department.

9.6 Suction Line

For the pump’s correct operation, the suction line must

have the following characteristics:

1. Minimum internal diameter as indicated in the diagram

in paragraph 9.9, and in any case equal or greater than

the pump head’s value.

Along the duct, avoid localized diameter reductions

that may cause pressure drops with subsequent

cavitation. Absolutely avoid 90

0

elbows, connections with

other hoses, bottlenecks, counter-slopes, upside down “U”

shaped curves, “T” connections.

2. The selected lay-out must allow to avoid cavitation.

3. It should be perfectly airtight, and built in a way that

guarantees perfect sealing over time.

4. Avoid pump emptying when stopping (even partial

emptying).

5. Do not use hydraulic-type fittings,3 or 4 way fittings,

adapters, etc. , since they may hinder the pump’s per

formance.

6. Do not install Venturi turbes or injectors for detergent

intake.

7. Avoid the use of standing valves, check valves, or any

other type of one-way valves.

8. Do not connect the by-pass line from the valve directly

to the pump suction line.

9. Provide appropriate baffle plates inside the tank in

order to avoid water that fows coming from both the by-

pass and feeding lines may create turbulance newr the

tanks outlet port.

10. Make sure that the suction line is perfectly clean inside

before connecting it to the pump.

The filter must be installed a close as possible to the

pump, should allow easy inspection and have the follow-

ing characteristics:

1. Minimum capacity 3 times greater than the pump’s

rated flow value.

2. Filter port diameters must not be smaller than the

pump inlet ports.

3. Filtration degree ranging between 200 and 360 µm.

9.7 Filtering

On the suction line, install 1 filter arranged as shown in fig.

6 and fig. 6/a.

With the manual adjustment valve:

With the pneumatic adjustment valve:

In order to guarantee correct pump operation,

it is important to plan periodical cleaning of

the filter depending on actual pump usage,

water quality and real clogging conditions.

Ref 300665 Rev.C

07-13