Kez series, General pump – General Pump KEZ Owner Manual v.1 User Manual

Page 8

GENERAL PUMP

A member of the Interpump Group

KEZ SERIES

Page 8

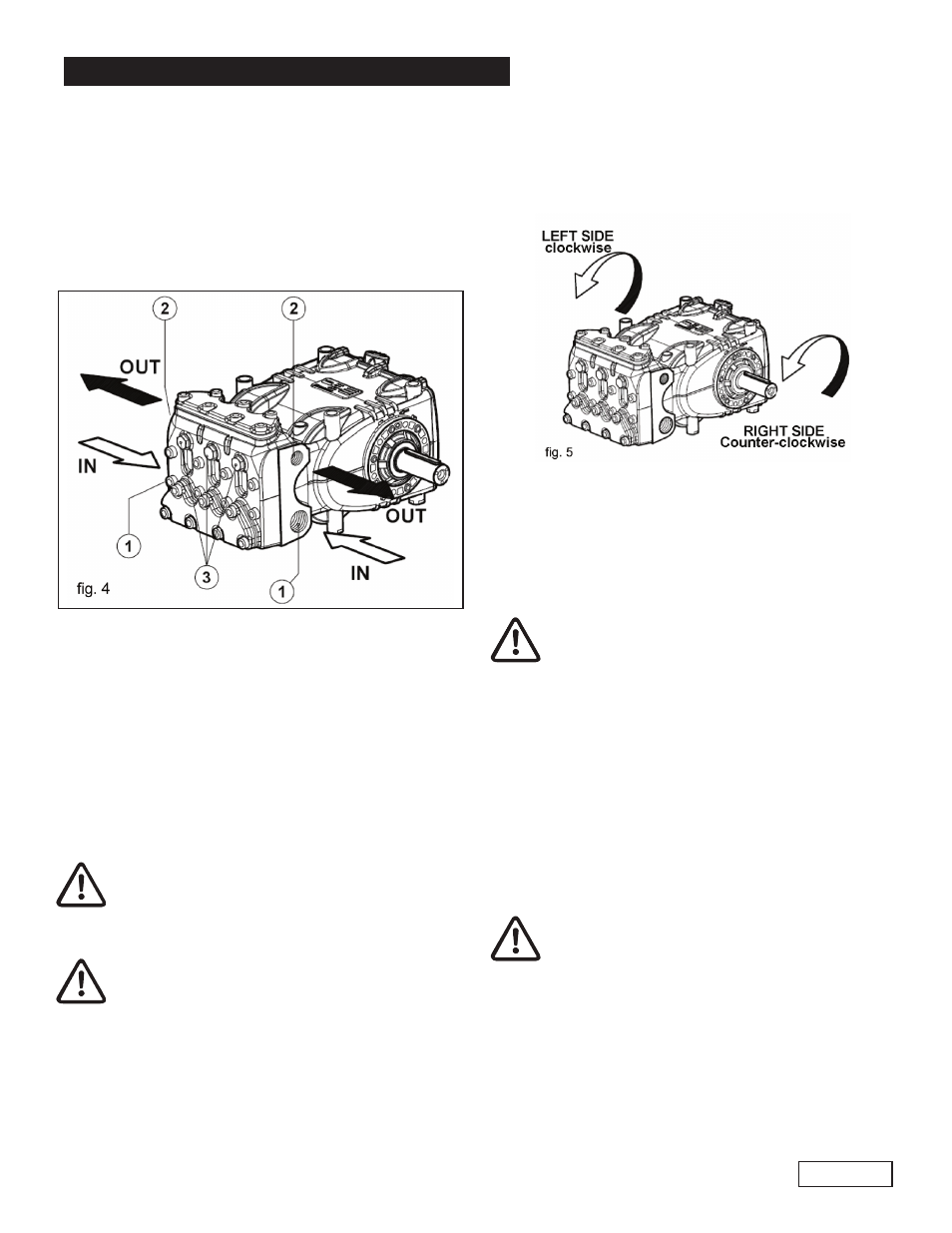

8. PORTS AND CONNECTIONS

KEZ Series pumps (see fig. 4) are provided with:

1. 2 inlet ports “IN”, 1” Gas. The line can be connected

to either of the two inlet ports; the ones not being

used must be hermetically sealed.

2. 2 outlet ports “OUT”, Ø 1/2” Gas

3. 3 auxiliary ports, 1/4” gas; used for the pressure

gauge only.

9. PUMP INSTALLATION

9.1 Installation

The pump must be installed in a horizontal position using

the correct threaded feet M12; fasten the screws with a

torque value of 59 ft. lbs (80 Nm). The base must be per-

fectly flat and sufficiently rigid in order to avoid bending and

misalignments on the pump/transmission coupling axis due

to the torque applied during operation. The unit must not be

rigidly fixed to the pavement, but requires the use of anti-

vibration elements. For special applications, please contact

the Customer Service Department.

Replace the oil cap (red), located on the rear

crankcase cover with the oil dipstick and

check oil level. The oil dipstick must always be

accessible, even when the unit is assembled.

The pump’s chaft (PTO) must not be rigidly

connected to the motor unit. The following

transmission

types

are

suggested:

• hydraulic by means of flange; for correct applica

tion, please contact the Customer Service

Department

• V-belt

• Cardan Joint (please respect the maximum

working angles indicated by the manufacturer)

• Flexible joint

9.2 Direction of rotation

An arrow situated on the crankcase near the shaft indi-

cates the correct direction of rotation. Standing in front of

the pump head, the direction of rotation must be a shown

in fig. 5.

9.3 Version Change

A right version pump is defined when: observing the pump

from the head side, the PTO shank is on the right side.

A left version pump is defined when: observing the pump

from the head side, the PTO shank is on the left side.

NOTE: Fig. 5 shows a right version.

The version may be changed only by special-

ized and authorized personnel by carefully fol-

lowing the instructions that follow:

1. Separate the hydraulic part from the mechan

ical part as indicated in Chapter 2, paragraph

2.2.1 of the repair manual.

2. Rotate the mechanical part by 180

0

, and repo

sition the rear crankcase cover so that the oil

dipstick is facing upwards; reposition the lifting

bracket and the related closing caps in the

upper part of the crankcase; finally, correctly

reposition the identification plate in its appro

priate seat on the crankcase.

Be sure that the lower draining holes on

the crankcase near the plungers are open,

and not closed by the plastic caps as

required for the previous version.

3. Join the hydraulic part with the mechanical

part as indicated in Chapter 2, paragraph

2.2.5 of the repair manual.