Kez series, General pump – General Pump KEZ Owner Manual v.1 User Manual

Page 13

GENERAL PUMP

A member of the Interpump Group

KEZ SERIES

In case the pump has not run for a long period

of time, verify the correct operation of the suc-

tion and delivery valves.

10.2 Start-up

1. When starting the pump for the first time, check for

the correct direction of rotation.

2. The pump must be started off-load.

3. Verify correct feeding pressure.

4. During operation check that the rotating speed does

not exceed the rated value.

5. Before putting the pump under pressure let it run for

at least 3 minutes.

6. Before stopping the pump, release the pressure by

acting on the adjustment valve or on any discharging

device, and reduce RPM (diesel applications).

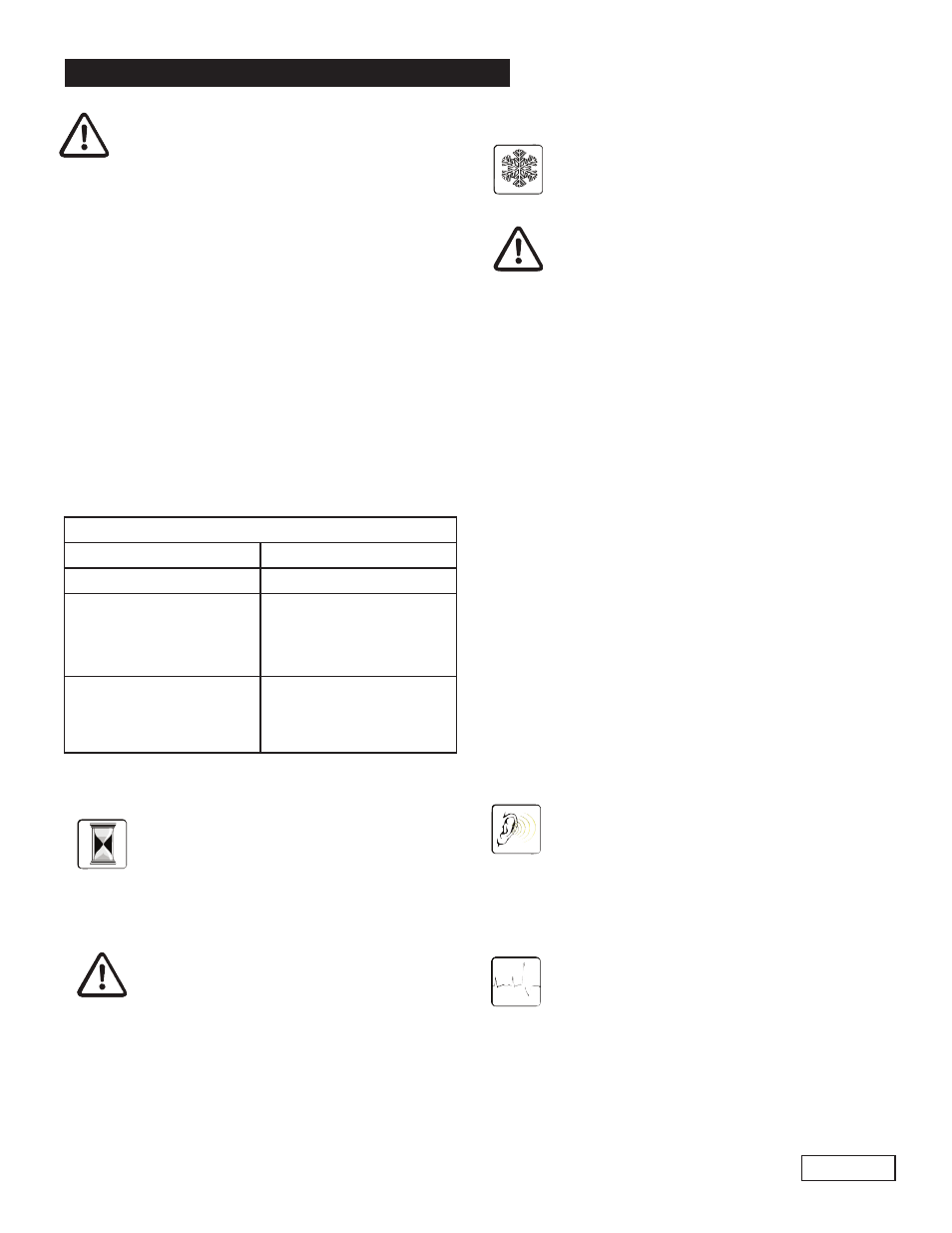

11. PREVENTIVE MAINTENANCE

PREVENTIVE MAINTENANCE

EVERY 500 HOURS

EVERY 1000 HOURS

Check oil level

Change oil

Check / Replace:

• Valves

• Valve seats

• Valve springs

Check / Replace:

• H.P packings

• L.P. packings

To guarantee pump reliability and efficiency, respect the

maintenance intervals as indicated in the table in fig. 14.

f

ig. 14

12. STOPPING THE PUMP FOR LONG PERIODS

12.1 Inactivity for Long Periods

If the pump is started up for the first time after a

long period from the shipment date, before start-

ing operation check the oil level, check the

valves as indicated in Chapter 10, and therefore

follow the start-up procedures described.

12.2 After Use

After use the pump should be drained. The use

of anti-freeze or preserving solutions is recom-

mended. Any hose connection needing to be left

disconnected should be properly protected and

greased.

13. PRECAUTIONS AGAINST FREEZING

In areas and periods of the year where there is

risk of freezing, follow the instructions indicated

in Chapter 11 (see paragraph 12.2).

In the presence if ice, in no case must the

pump be started until the entire circuit has

been completely thawed out; not complying

with this indication may cause serious

damage to the pump.

14. WARRANTY TERMS

The duration and the terms of the warranty are contained

in the purchase contract. The warranty is void if:

a) The pump has been used for purposes that differ

from that agreed.

b) The pump has been fit with an electric or diesel

engine with performance greater than that indicated

in the table.

c) The required safety devices were un-adjusted or dis

connected.

d) The pump was used with accessories or spare parts

not supplied by General Pump.

e) Damage was caused by:

1) improper use

2) the non-observance of maintenance instructions

3) use not compliant with operating instructions

4) insufficient flow rate

5) faulty installation

6) incorrect positioning or sizing of the hoses

7) non-authorized design changes

8) cavitation

15. TROUBLESHOOTING

The pump does not produce any noise at

start-up:

• The pump is not primed and is running dry

• There is no water in the inlet line

• The valves are blocked

• The delivery line is closed and does not allow

the air in the pump to be discharged

The pump pulses irregularly (knocking):

• Air suction

• Insufficient feeding

• Bends, elbows, fittings along the suction line

obstruct the fluid’s passage

• The inlet filter is dirty or too small

• The booster pump, where provided, supplies

insufficient pressure or flow rate

• The pump is not primed due to insufficient

head or the delivery line is closed during

priming

Page 13