Hf series, General pump – General Pump HF Owner Manual User Manual

Page 7

GENERAL PUMP

A member of the Interpump Group

HF SERIES

Page 7

9. PUMP INSTALLATION

9.1 Positioning

The pump must be installed on a rigid and perfectly flat

and horizontal base by means of the proper four M16 x 1.5

threaded feet. The base should be rigid enough to avoid

any misalignment or flexing on the pump/transmission cou-

pling axis due to the torque involved during operation.

The unit should not be rigidly fixed on the floor

but be installed upon vibration dampeners. For

special applications contact our technical department.

An eye-bolt is provided on top of the crankcase for easy

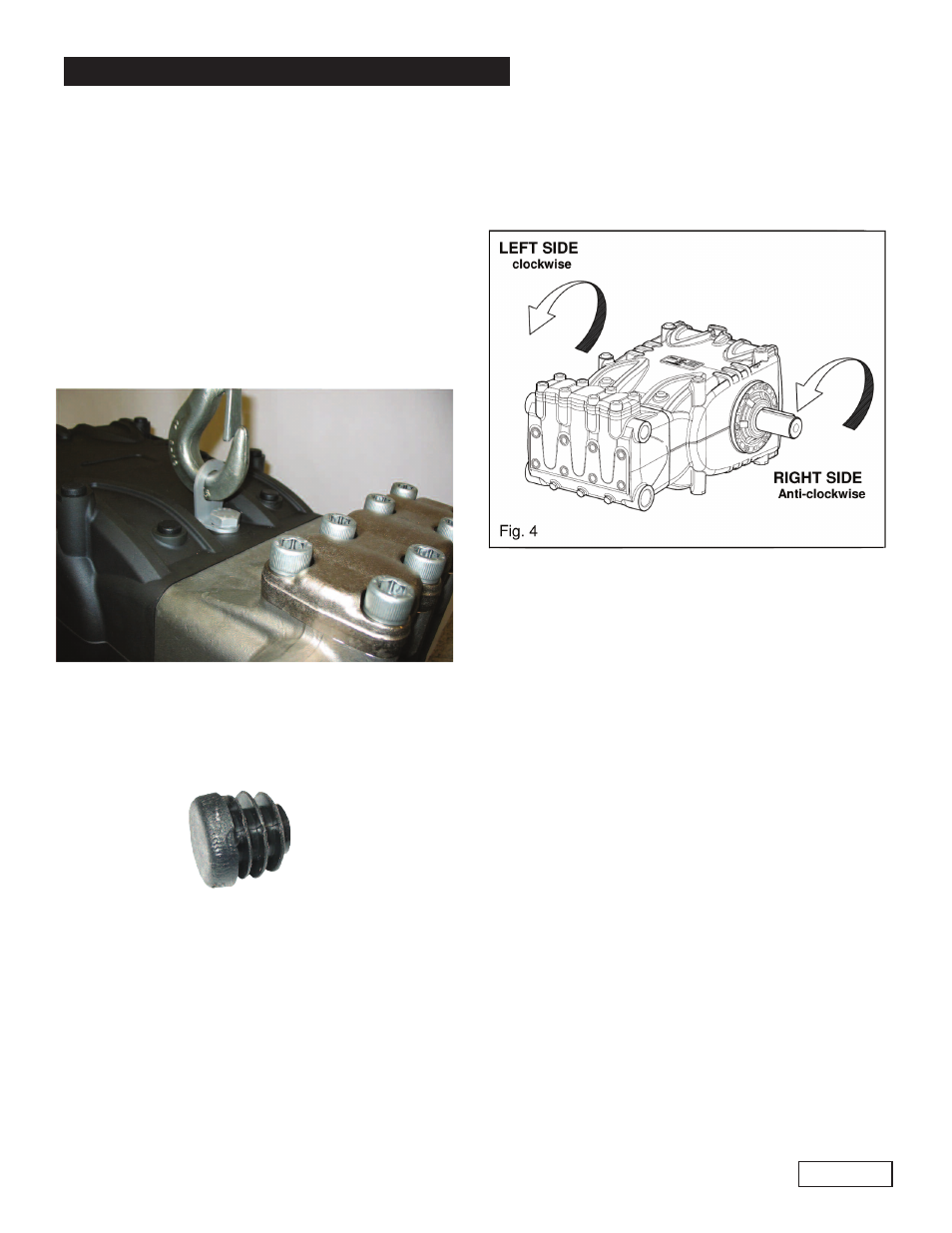

handling of the pump (see picture below).

9.2 Direction of rotation

An arrow situated on the crankcase near the shaft

indicates the correct direction of rotation. Fig. 4 shows

the direction of rotation looking at the pump from

the fluid end side.

9.3 Water connections

In order to isolate the high pressure equipment from the

pump vibrations it is suggested, where applicable, to use

flexible hoses for both suction and delivery lines at least

for the first length. The flexible suction hose must be

rigid enough to prevent it from collapsing during the

suction stroke, when a partial vacuum may occur.

9.4 Suction line

The pump life is considerable influenced by the effective-

ness of the suction line which must have the following

characteristics:

1. The internal diameter of the suction line should be at

least 30 mm (see the diagram on point 9.7) in any

point, possibly larger depending on the drop in

pressure due to the length and shape of the line.

2. It should be as straight as possible minimizing

changes in size and direction and positioned in such

a way to allow air pockets and bubbles to escape.

3. It should be perfectly airtight.

4. It should be completely free from 90o elbows, diameter

reductions, counter slopes, “T” connections and and

should not be connected with other pipelines.

5. It must be positioned in such a way to prevent the pipe

emptying after the pump stops.

6. Do not use high pressure hydraulic fittings like 90

o

elbows, high pressure adaptors, high pressure 3 or 4

way nipples, and so on.

7. Do not install any kind of detergent infector along the

suction line.

8. Do not install standing valves, check valves or other

The eye bolt can be replaced with a plastic cap (see

below), in order to protect the thread in the crankcase.

The plastic cap is provided with the pump.

The oil plug must absolutely be replaced by the oil

stick and the oil level checked. Make sure that you can

easily reach the oil stick even after the unit has been

assembled.

Never use rigid coupling on the shaft.

The following transmission types are suggested:

-

Hydraulic by means of a flange

-

Pulleys

-

Cardan joint (within the max working angles indicated

by the manufacturer).