Hf series, General pump – General Pump HF Owner Manual User Manual

Page 13

GENERAL PUMP

A member of the Interpump Group

HF SERIES

Page 13

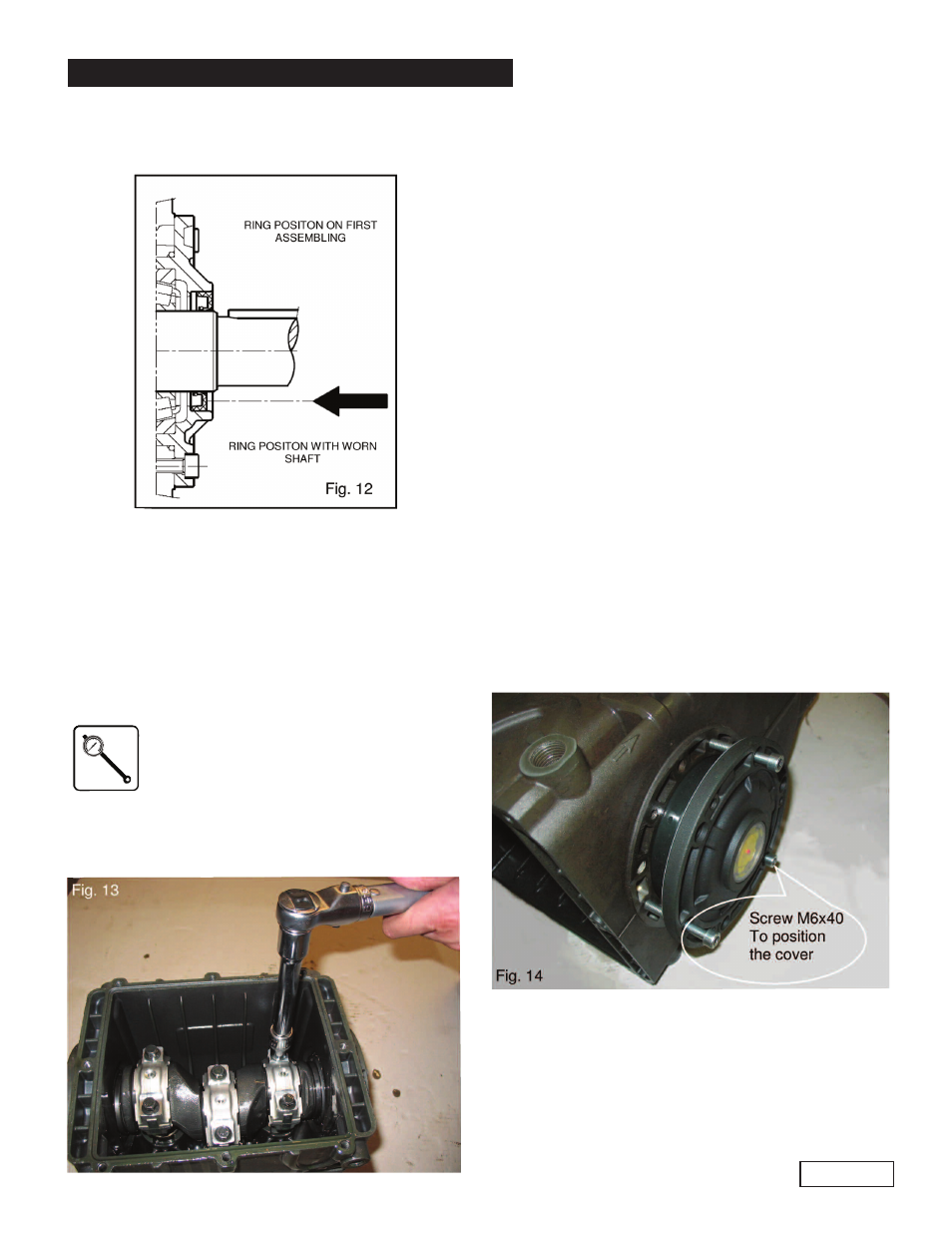

C) Before reassembling the side covers, check the seal

lips for wear. If they need replacing, fit the new ring

following the indications in Fig. 12.

E) Fit the back cover putting the dipstick hole upward.

11.1.3 Disassembling / Reassembling of the bearings

and shims

The type of bearings (conical roller) ensures there is no

end float on the crankshaft; the shims are to be determined

to reach that purpose. To disassemble, reassemble and if

required replace them, it is absolutely necessary to do as

indicated below.

Disassembling / reassembling of the crankshaft

without replacing the roller bearings

After removing the side covers, as indicated on point

11.11.1, check the rollers and reces for wear; if they are in

good state, accurately clean the components with suitable

degreaser and grease them again evenly with oil (same as

the pump oil).

The same shims can be used again, taking care to fit them

under the sight glass cover.

After installing the complete unit (sight glass side flange +

crankshaft + engine side flange), check that the rolling

couple - with connecting rods free - is at least 4 Nm, max

7 Nm.

To position the two side covers on the crankcase, you

can use 3 screws (M6 x 40) first, and then the original

screws to fix them.

The rolling couple of the crankshaft (with connecting rods

coupled) must not exceed 8 Nm.

NOTE: Should the shaft show diameter wear in the seal

position, it is possible to avoid grinding it by fitting the

seal further as indicated in Fig. 12. Before installing the

cover, (sight glass side) check the shim rings have been

placed. To help the covers fit on the crankcase, you can

use 3 screws M6 x 40, and then finish screwing them

with the original bolts (M16 x 18).

D) Install the connecting rod cap taking care the

numbers match and tighten the relevant bolts in 3

different stages:

1.

Approach torque 6-8 Nm

2.

Presetting torque 25-28 Nm

3.

Tightening torque 38 Nm

NOTE: The screws must be greased on the thread and

under the head.