Welch Vacuum 2546 WOB-L Pinston Pump User Manual

Page 9

9

Section 6: MAINTENANCE

6.10 MAINTENANCE ON A WELCH PRESSURE / VACUUM PUMP

Welch dry pressure/vacuum units are 100% oil-free. The pump employs a non-lube piston

and cylinder. No maintenance is necessary for the bearings. All bearings are sealed and

permanently lubricated. Lubrication should not be attempted. The units are built for continuous

duty operation with the quietness and durability of a diaphragm, but with piston performance.

Section 7: TROUBLESHOOTING

7.10 VACUUM PROBLEMS

Leakage, contamination, and unusual outgassing are the general causes of problems

associated with poor vacuum. To operate at maximum effi ciency, a system must be thoroughly

clean. If the system is completely clean and free from leaks, and unwarranted vacuum

problems still exist, the pump should be checked. A simple criterion for the condition of the

pump is the determination of its maximum vacuum capability. This can be accomplished by

blocking of the intake and reading the vacuum level on the gauge

7.20 PRESSURE PROBLEMS

Leakage and contamination are the general causes of problems associated with poor

pressure. To operate at maximum effi ciency a system must be thoroughly clean. If the system

is completely clean and free from leaks, and unwarranted pressure problems still exist, the

pump/compressor should be checked by a service technician.

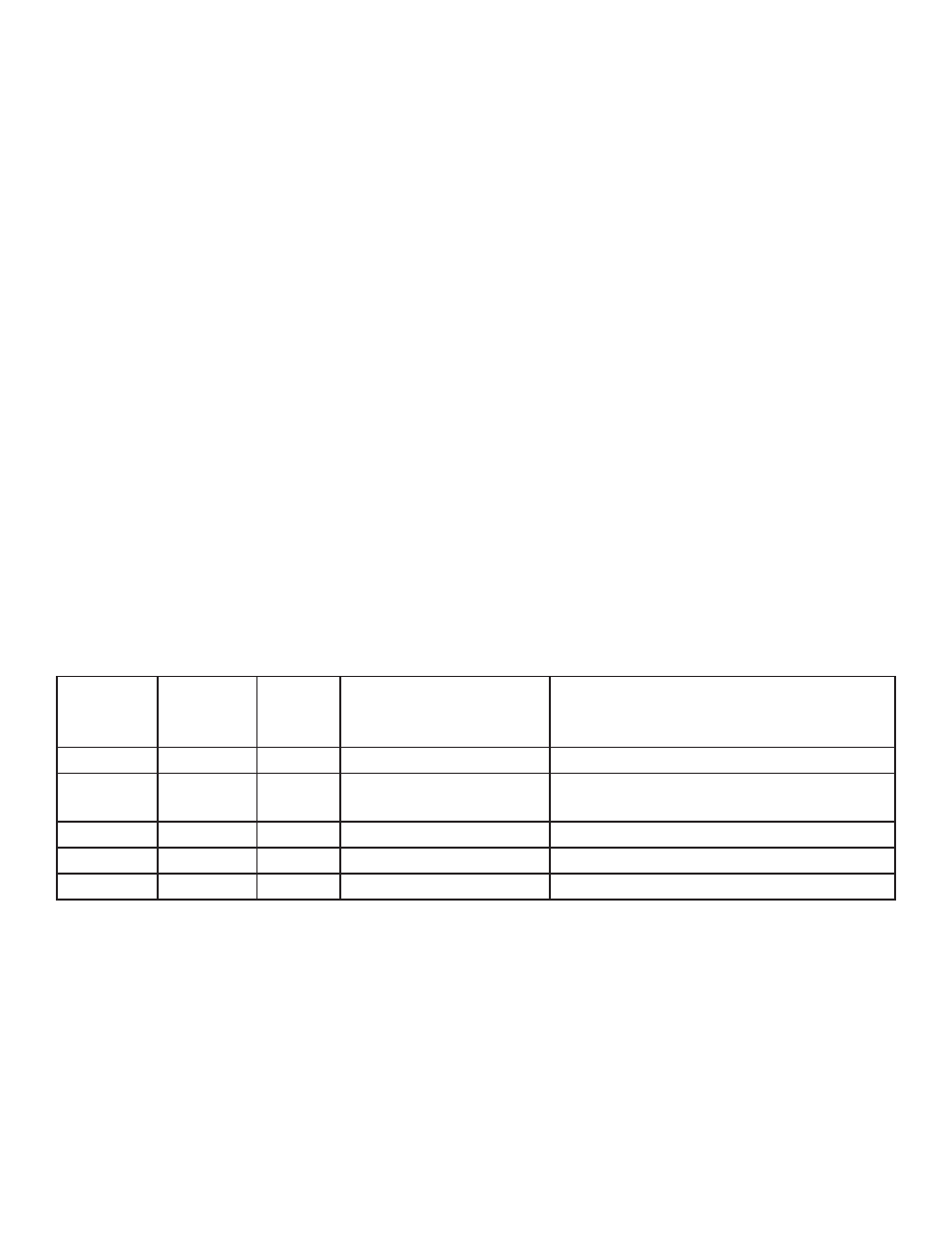

7.30 TROUBLESHOOTING GUIDE

Poor

Pumping

Speed

Poor

Pressure

Loud

Unit

Possible Cause

Corrective Action

X

X

X

Damaged valves

Replace fl apper valves

X

X

X

Debris in valves

Remove debris and check for valve

damage

X

X

X

Damaged gasket

Replace gasket

X

X

X

Loose head screw

Tighten head screw

X

X

X

Loose fi tting

Tighten fi tting