Installation, Temperature control, Water supply – Fulton Electric (FB-W) Hot Water Boiler User Manual

Page 11: Step controllers, Water quality, Water specifi cation

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

SECTION 2

FBW-IOM-2014-0311

INSTALLATION

2-5

Drain Valve

PID Type Temperature Controller

Boilers 100kW and larger: staged element sequencer for

modulation of output

Temperature Control

Temperature control is achieved via an operating and high

limit temperature controller. The high limit temperature

controller is a temperature switch that is set to shut the boiler

off if the water temperature exceeds the set point. For ASME

Section IV hot water boiler, the high limit must be below 250

F.

The operating controller is a temperature sensor and PID

Type controller that converts a temperature measurement

into a 4-20 ma signal. The signal, which is proportional to the

temperature of the water in the boiler, is used to energize/de-

energize the contactors or step controller. The step controller

(power modulation) will energize/de-energize each element

based on a preset sequence to maintain the outlet water at a

preset temperature.

Step Controllers

At start up stage number one is fi rst “on” with additional

stages added as demanded. When set point is reached, the

fi rst “on” stage is removed followed by the next stage “on”.

Where control is a fraction of the total load, a sequence of on-

steps will advance through the total number of stages, trailed

by a sequence of “off ” steps. In this way all contactors and

heaters tend to operate equally.

A back up operating temperature switch is supplied on each

boiler and will act to energize/de-energize all elements

simultaneous based on boiler water outlet temperature.

Water Supply

Water Quality

The quality of the water used in the boiler will aff ect the

life of the elements and pressure vessel and it is strongly

recommended that a competent water treatment concern

be consulted prior to the operation of the boiler. Boiler

internals damaged due to adverse water conditions cannot

be replaced under warranty.

Water Specifi cation

All water supplies contain some amount of solids, dissolved

gases and dissolved minerals. These materials may promote

corrosion, deposition and/or fouling of equipment. To prevent

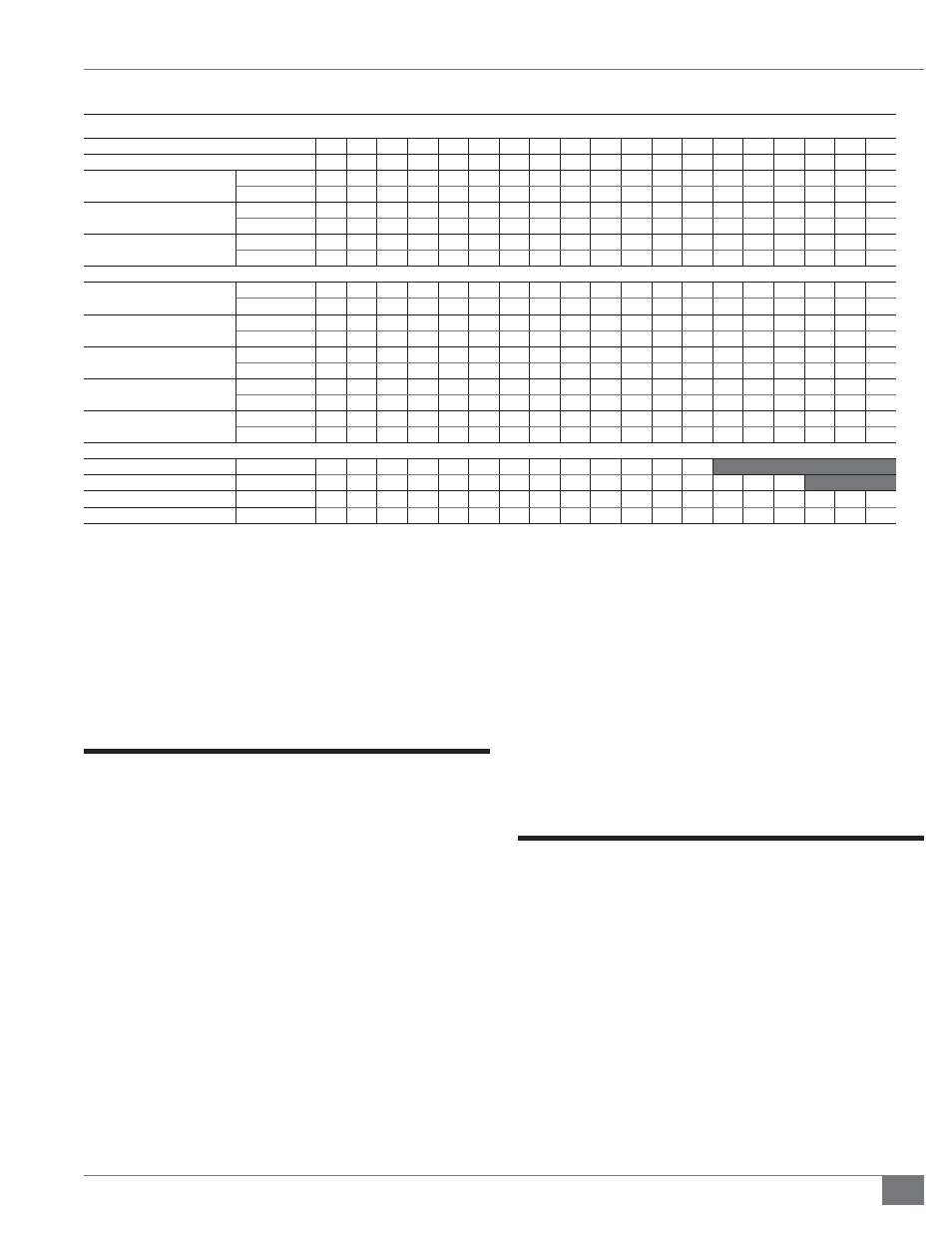

TABLE 1B - SPECIFICATIONS

Model FB-W

012

015

018 024 030 036 050 070 105 140 175

210 280 350 420 490 560 630 700

Number of Elements

1

1

1

2

2

2

2

2

3

4

5

6

4

5

6

7

8

9

10

Output

1000 BTU/HR

41

51

62

82

103

124

172

241

362

483

603

724

966 1207 1449 1690 1932 2173 2415

1000 KCAL/HR

10

13

16

21

26

31

43

61

91

122

152

182

243

304

365

426

487

548

609

Approx. Shipping Weight

LB 420

420

420

450

450

450

580

580

950 1088 1225 1225 1380 1615 1850 2039 2150 2320 2660

KG 191

191

191

204

204

204

263

263

431

494

556

556

626

733

839

925

975 1052 1207

Water Capacity

GALLONS

13

13

13

13

13

13

21

21

51

51

68

68

132

133

133

169

169

234

234

LITERS

49

49

49

49

49

49

79

79

193

193

257

257

500

503

503

640

640

886

886

Heater Connection Sizes

Hot Water Outlet

IN 1.25 1.25 1.25 1.25 1.25 1.25

2

2

2

2

2

2

2

2

2.5

3

3

3

3

MM

32

32

32

32

32

32

51

51

51

51

51

51

51

51

64

76

76

76

76

Hot Water Inlet

IN 1.25 1.25 1.25 1.25 1.25 1.25

2

2

2

2

2

2

2

2

2.5

3

3

3

3

MM

32

32

32

32

32

32

51

51

51

51

51

51

51

51

64

76

76

76

76

Drain Outlet

IN

1

1

1

1

1

1

1

1

1

1

1.25 1.25 1.25 1.25

1.5

1.5

1.5

1.5

1.5

MM

25

25

25

25

25

25

25

25

25

25

32

32

32

32

38

38

38

38

38

Safety Valve Inlet (160 PSIG)

IN 0.75 0.75 0.75 0.75 0.75 0.75 0.75 0.75 0.75 0.75 0.75 0.75 0.75 0.75 0.75 0.75 0.75 0.75 0.75

MM

19

19

19

19

19

19

19

19

19

19

19

19

19

19

19

19

19

19

19

Safety Valve Outlet (160 PSIG)

IN

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

MM

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

Electrical Power Requirements (Amps)

208V 3 Phase

34

42

50

67

84

100

139

195

292

389

486

583

778

Consult Factory

230V 3 Phase

31

38

46

61

76

91

126

176

264

352

440

528

703

879 1055 1231

Consult Factory

460V 3 Phase

16

19

23

31

38

46

63

88

132

176

220

264

352

440

528

616

703

791

879

575V 3 Phase

13

16

19

25

31

37

51

71

106

141

176

211

282

352

422

493

563

633

703

Specifi cations are approximate.

Fulton reserves the right to change dimensions and/or specifi cations without notice. Voltage applied higher than the above ratings will

result in higher amp draws. 160 PSIG design boilers operate up to 130 psi, 230 F.