Fill-Rite FR313 REMOTE PUMPS User Manual

Page 3

Model FR713

Full 1/3 HP, 220/240 VAC, 50/60Hz motor

Pumps are furnished with factory installed anti-siphon devices

and must be installed in accordance with the applicable

requirements of the Automotive and Marine Service Station

Code, NFPA No. 30A, and the National Electrical Code, NFPA

No. 70. They are designed for use either inside or outside of

buildings subject to the acceptance of inspection authorities

having jurisdiction at points of installation.

Complete installation must include one (or more) UL listed

remote dispenser(s) with a UL listed emergency shut-off

valve with fusible link located at dispenser inlet. If a non-UL

listed dispenser is used without a solenoid valve, the system

must consist of one dispenser only. All piping should be

Schedule 40. Use UL classified gasoline and oil resistant pipe

compound on all threaded joints.

See Remote Dispenser Owner's Operation & Safety Manual for

complete installation and operation instructions. The following

dispensers are available from Fill-Rite.

Model 317 "Weights & Measures" Elite

Models 315S, 315ST with ±2% accurate meter

Model FR307 AST "Weights & Measures", UL listed

Models FR305R, 305R AST with ±2% accurate meter

Pump has a built-in check valve with pressure relief to prevent

fluid thermal expansion from causing unsafe system pressures.

DO NOT USE ADDITIONAL CHECK VALVES OR FOOT

VALVES UNLESS THEY HAVE PROPER PRESSURE RELIEF

VALVES BUILT INTO THEM.

Mechanical Installation

Mount pump securely on top of tank in proper position for

connecting piping to dispenser. Tighten pump by using pipe

wrench ONLY on tank adapter, being careful not to damage

anti-siphon return line.

The FR713, 303, and the 313 require a 1¼" suction pipe.

3

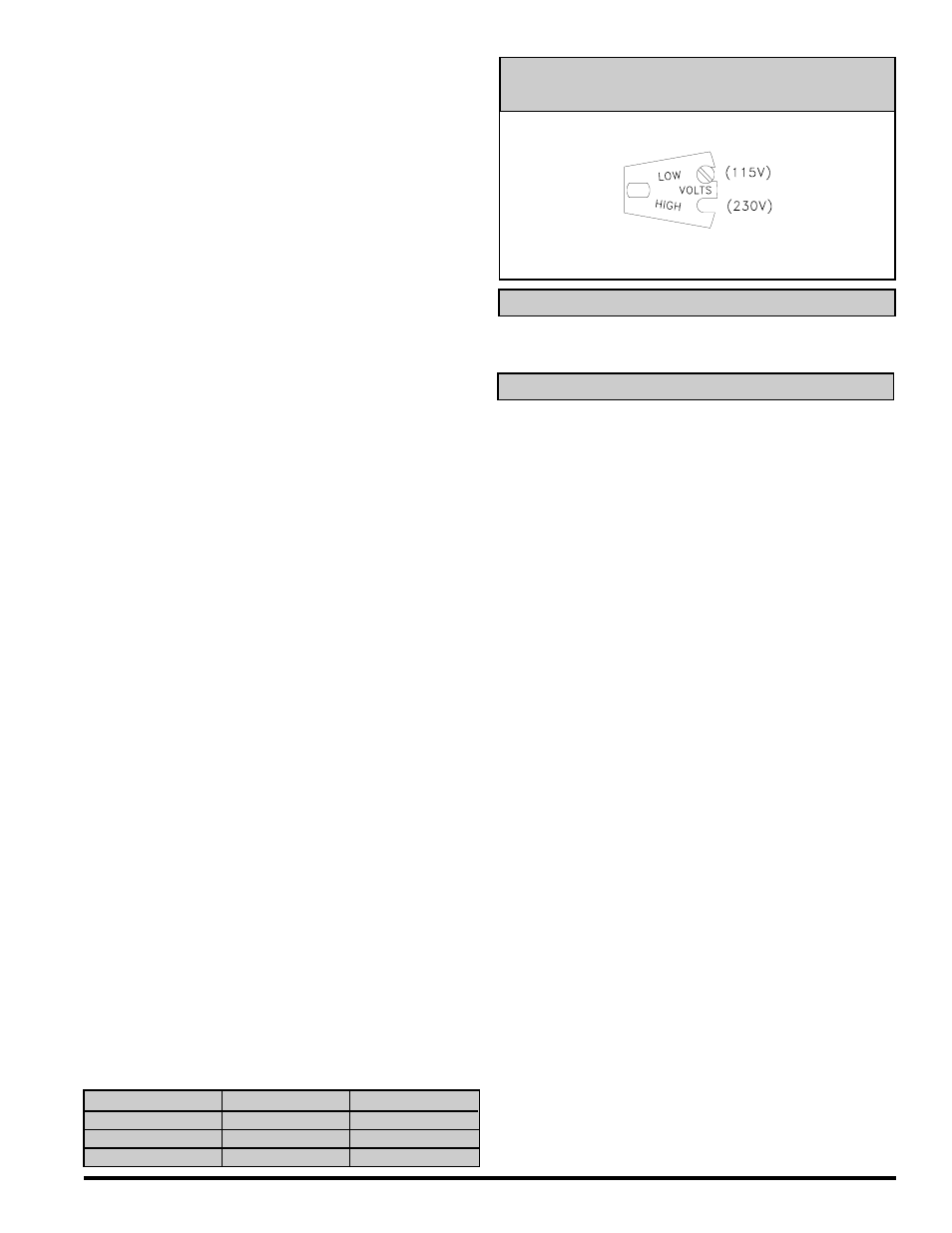

MODELS 303, 313

Franklin motors

Voltage select screw should be placed next to

correct voltage setting (115VAC shown)

VOLTAGE SELECTION SWITCH

Models 303 and 313 Design Features:

Inlet: 2" male NPT on bung, 1¼" female NPT on suction pipe

Outlet: 1" NPT

Built in check valve, bypass and pressure relief valves.

(Anti-siphon device prevents thermal expansion pressure

buildup.)

CAUTION: DO NOT INSTALL ADDITIONAL FOOT

VALVE OR CHECK VALVE DURING INSTALLATION

WITHOUT PRESSURE RELIEF VALVE. HOUSING

OR PLUMBING CRACKING MAY RESULT.

Cast iron pump housing: bronze rotor and carbon vanes

Overall Dimensions: 14¾" (37.5cm) wide x 14½" (36.8cm)

high x 7¾" (19.7cm) deep

Explosion proof motor

313: ¾ HP 115/230 VAC-60Hz dual voltage motor, 1725

RPM, 11 amps at 115 VAC or 5.5 amps at 230 VAC

303: ½ HP 115/230 VAC-60Hz dual voltage motor, 1140

RPM, 9.2 amps at 115 VAC or 4.6 amps at 230 VAC

Thermal overload protection

Ball bearing construction; no greasing or oiling required

Models 303 & 313 Performance:

25 psi (1.72 bar) maximum outlet pressure

313: up to 30 gpm (114 lpm)

303: up to 20 gpm (76 lpm)

Maximum viscosity of fluid pumped: diesel fuel

Maximum operating ambient temperature: 150°F

(65.6°C)

Minimum operating ambient temperature: -15°F (-27°C)

(Consult factory for extreme temperature applications)

Minimum dry vacuum: 14" (35.6cm) of mercury

Minimum suction lift: 10' (3m) for gas & 18' (5.5m) for diesel

fuel. The lift in feet is equivalent to the vertical distance

from the surface of the fluid in the tank to the inlet of the

pump, PLUS the friction losses through the vertical and

horizontal runs of pipe, all elbows and other fittings. Sys-

tems should be designed to require a minimum amount

of suction lift.

Fluid Compatibility

The FR713, 303, and the 313 are compatible with the

following fluids:

Diesel, Gasoline, Kerosene, Mineral Spirits, Heptane,

and Hexane

NOTE: Only the 303 and FR713 versions are

recommended for gasoline applications.

The FR713, 303, and the 313 are NOT compatible with the

following fluids:

Acetone, Ammonia, Benzene, Bleach, Hydrochloric

Acid, Ink, and Toluene

If in doubt about compatibility of a specific fluid, contact

supplier of fluid to check for any adverse reactions to the

following wetted materials.

Cast Iron

Steel

Stainless Steel

Bronze/Iron

Carbon

Polyester

Fiber

Viton

Buna N

Zinc Plated Steel

Ceramic

Aluminum

OPTIONS

INSTALLATION