BVA Hydraulics PAR1703, PARD1701, PARD1703, PARM1703 User Manual

Page 7

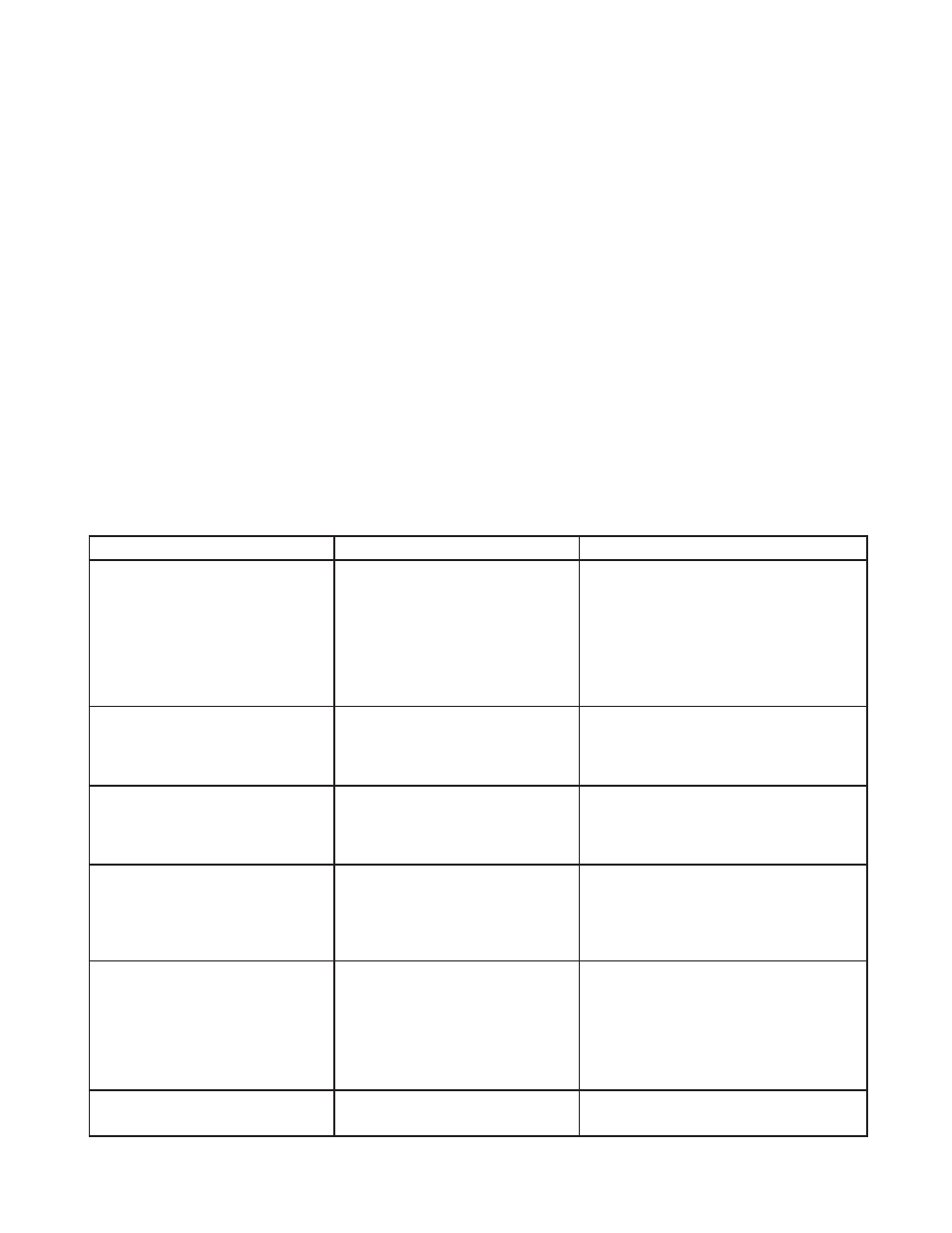

TROUBLESHOOTING GUIDE

The following information is intended as an aid in determining if problem exists. Pumps should be repaired only by authorized

BVA Service Center. For repair service, contact service center in your area.

7

Symptom

Possible Causes

Corrective Action

Application does not extend, move or

respond to pressurized fluid

• Overload condition

• Loose couplers

• Faulty couplers

• Pump malfunction

• Inadequate air supply

• Remedy overload condition

• Tighten couplers

• Replace couplers

• Contact service center

• Ensure air source can dedicate:

44 CFM @ 80 psi for 1.7 hp pumps

Application responds to pressurized

fluid, but system does not maintain

pressure

• Overload condition

• Pump or valve malfunction

• Application/connection leaking

• Remedy overload condition

• Contact

Service Center

• Replace application/connection

Application responds slower than

normal

• Loose connection or coupler

• Restricted hydraulic line or fitting

• Application/connection leaking

• Tighten connection or coupler

• Clean and replace if damaged

• Replace application/connection

Application does not return fluid to

pump (i.e. cylinder will not retract)

• Malfunctioning coupler, damaged

application

•

Secure load by other means-

Depressurize pump and hose, remove

coupler and/or application, then renew or

replace

Application does not fully extend

(cylinder or spreader)

• Reservoir overfilled

• Fluid level in pump is low

•

Secure load by other means-

Depressurize pump and hose, remove

application, then drain fluid to proper level

•

Secure load by other means-

Depressurize pump and hose, remove

application, then fill fluid to proper level

Poor performance

• Fluid level in pump is low

• Ensure proper fluid level

MAINTENANCE

Important: Use only good quality hydraulic fluid. Never use

brake fluid, transmission fluid, turbine oil, motor oil, alcohol,

glycerin etc. Use of other than good quality hydraulic oil will

void warranty and damage the pump, hose, and application.

We recommend Mobil DTE 13M or equivalent.

1. Inspect hoses and connections daily. Replace damaged

components immediately.

2. Tighten connections as needed. Use non-hardening pipe

thread compound when servicing connections.

Adding Hydraulic Fluid

1. Depressurize and disconnect hydraulic hose from

application/ cylinder.

2. With pump in its upright, horizontal position, remove the

air vent plug located on the top plate of the reservoir.

3. Use a small funnel to fill the oil to within 3/4" (19mm)

of the opening.

4. Wipe up any spilled fluid and reinstall the air vent plug/

reservoir cap.

Changing Hydraulic Fluid

1. For best results, change fluid once a year or every 300

hours of use.

2. Repeat # 2 above, then pour used fluid into a sealable

container.

3. Dispose of fluid in accordance with local regulations.

4. Fill with a good quality hydraulic fluid as recommended

above. Reinstall air vent plug/ reservoir cap.

Lubrication

When pump is operated on daily basis, the manufacturer

recommends installing an inline oiler and air dryer. Use

SAE grade oil (5W to 30W).

Storage

1. When not in use, depressurize and disconnect hydraulic

pump from application.

2. Wipe clean, thoroughly and store in clean, dry

environment. Avoid temperature extremes.

3. For transportation or long storage, replace the air vent

plug with shipping plug.