BVA Hydraulics PAR1703, PARD1701, PARD1703, PARM1703 User Manual

Page 6

6

To reduce the risk of personal injury and/or property

damage, hydraulic connections must be securely

fastened before building pressure in the system. Release

all hydraulic pressure by disconnecting air source and

actuating the 'dump' valve (PARD series)

or moving the

pump lever to 'neutral' (PAR,PARM series)

and disconnect

air source from pump

before loosening any hydraulic

connection in the system.

Always monitor pressure, load or position using

suitable equipment. Pressure may be monitored by

means of an optional manifold and gauge. Load may be

monitored by means of a load cell and digital indicator.

Correct application position can only be determined by the

operator of the equipment.

These valves

will reposition the load during

handle movement. The amount of load movement

will depend on the speed of the handle movement

between detent positions.

!

OPERATION

(refer to schematic flow path, page 5)

PAR1703 (refer to Figure 5, 7)

1. Check oil level, add oil if necessary.

2. Make sure system fittings and connections are tight and

leak free.

3. Place control valve lever in the middle (Neutral/Hold)

position to prevent accidental lifting or moving of load.

OPERATION

(continued)

PARD1701, PARD1703 (see Figure 8)

These pumps are for use with a single acting

cylinder ONLY! Connect one hose from either

pump oil output port to the input port of a single acting

application such as a cylinder. Block the unused output

port securely. This model

can not be used with double

acting cylinders.

!

Port A

Port B

1

2

3

Figure 7- 3-position valve (all except PARD series)

4. To

start the air motor:

4a. Ensure direction control valve lever is in the '2' (neutral)

position.

4b. Connect air source to input air connection.

5. To direct fluid to and from the application:

5a. Move lever to position '1' to cause fluid to move to the

application. Maintain control valve position until the

desired pressure, load or position is reached.

Note: Do

not continue to operate pump after cylinder plunger is fully

extended or retracted.

5b. Always monitor pressure, load or position using suitable

equipment.

Do not load a hydraulic application (cylinder,

spreader, etc.) to more than 80% of its rated capacity.

5c. Shift the control valve until the desired pressure, load or

position is reached.

Note: Do not continue to operate pump

after cylinder plunger is fully extended or retracted.

5d. Move lever to position '3' to cause fluid to return to the

tank (reservoir).

To turn air motor off:

6. Maintain lever position '3' to depressurize the system.

6a. Disconnect air source from input air connection.

PARM1703 (refer to Figure 6, 7)

These pumps are for use with a single acting

cylinder ONLY! Connect one hose from either

pump oil output port to the input port of a single acting

application such as a cylinder. Block the unused output

port securely. These models

can not be used with double

acting cylinders.

!

4. To

start the air motor:

4a. Ensure direction control valve lever is in the '2' (neutral)

position.

4b. Connect air source to input air connection.

5. To direct fluid to and from the application:

5a. Move lever to position '1' to cause fluid to move to the

application. Maintain control valve position until the

desired pressure, load or position is reached.

Note: Do

not continue to operate pump after cylinder plunger is fully

extended or retracted.

5b. Always monitor pressure, load or position using suitable

equipment.

Do not load a hydraulic application (cylinder,

spreader, etc.) to more than 80% of its rated capacity.

5c. Shift the control valve until the desired pressure, load or

position is reached.

Note: Do not continue to operate pump

after cylinder plunger is fully extended or retracted.

5d. Move lever to position '3' to cause fluid to return to the

tank (reservoir).

To turn air motor off:

6. Maintain lever position '3' to depressurize the system.

6a. Disconnect air source from input air connection.

!

These pumps are for use with a double acting

cylinders ONLY! They can not be used with

single acting cylinders. Ensure that both A and B ports are

properly connected to a double acting application.

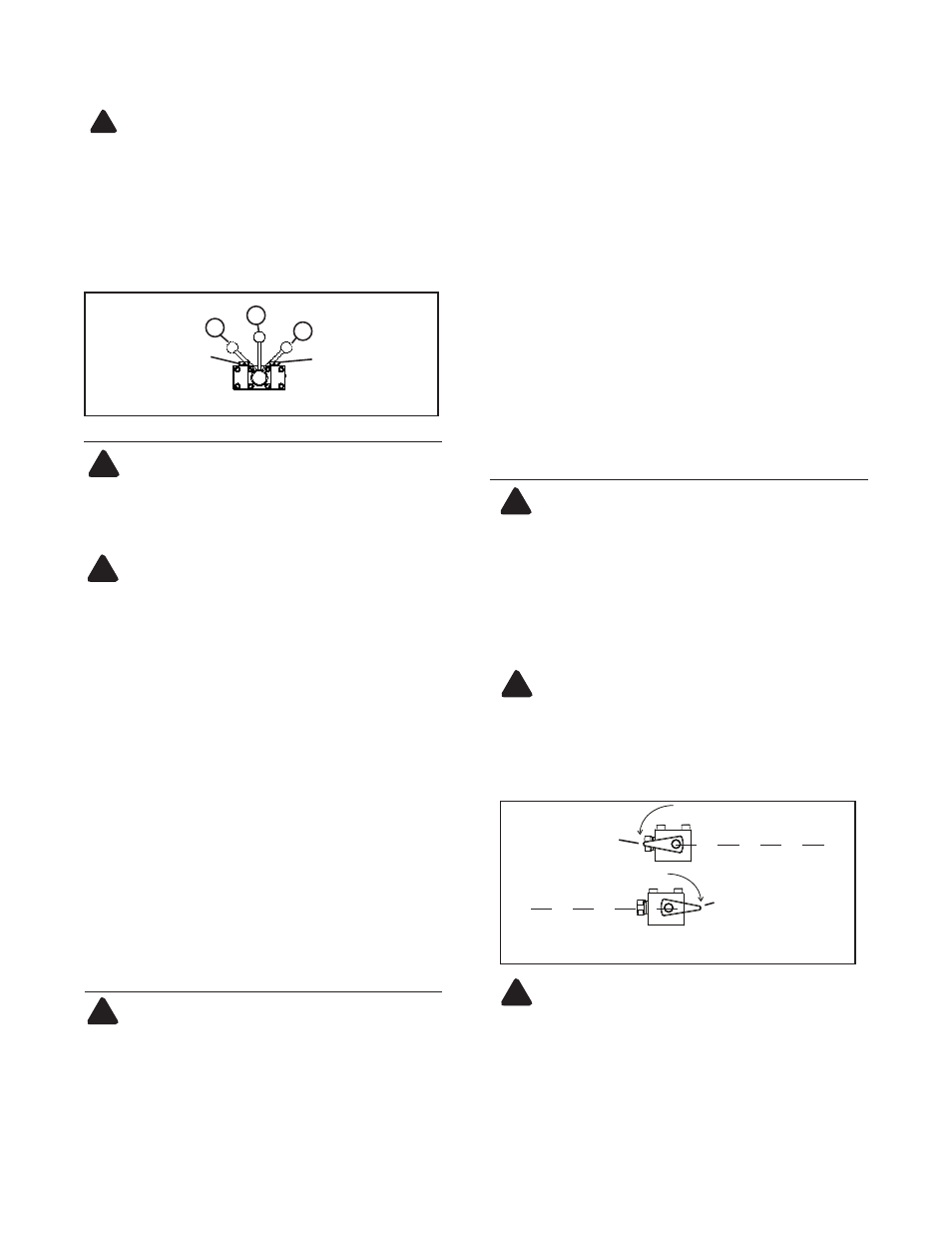

Figure 8- Dump Valve Lever Positions

horizontal

horizontal

"HOLD" position:

will advance, then

hold cylinder when

motor off

"RELEASE" position:

will advance unloaded

cylinder, retract

loaded cylinder

!

!

1. Check oil level, add oil if necessary.

2. Make sure system fittings and connections are tight and

leak free.

3. Place control valve lever in the middle (Neutral/Hold)

position to prevent accidental lifting or moving of load.

1. Check oil level, add oil if necessary.

2. Make sure system fittings and connections are tight

and leak free.

3. Connect to air source.

Once connected to the intended air source, pump

will be energized and oil will flow from the pump to the

application.

ENSURE operator is aware that application

will be pressurized

immediately upon connecting air

source.

PARD1701, PARD1703:

!

4. See Figure 8 below for details.