BVA Hydraulics PEW0501T, PEW1002T, PEW1503T, PEW1505T, PEW3005T User Manual

Page 6

3. Remove vent cap on the top plate of the reservoir.

4. Use a funnel to fill reservoir to about 2" from top of reservoir

plate.

5. Wipe up any spilled fluid and reinstall the vent cap.

Changing Hydraulic Oil

1. For best results, change hydraulic oil once a year.

2. Remove drain plug, tilt the pump then pour used fluid into

a sealable container.

3. Dispose the hydraulic oil in accordance with local

regulations.

4. Fill hydraulic oil, then reinstall vent cap.

Cleaning

Clean oil filter screen periodically with nonflammable solvent,

then blow dry before reassemble back to pump.

Storage

1. When not in use, depressurize and disconnect hydraulic

hoses from application.

2. Wipe clean, thoroughly.

3. Store in clean, dry environment. Avoid temperature

extremes.

4. For transportation or long term storage, shield pump with

a protective cover.

6

TROUBLESHOOTING

A system failure may or may not be the result of a pump malfunction. The following information is intended to be used as an

aid in determining if a problem exists.

Pumps should be repaired only be repaired by authorized BVA Service Center.

MAINTENANCE

1. Keep areas around pump unobstructed in order to provide

good air flow around the motor and pump. Try keep the

motor and pump as clean as possible.

2. Inspect hoses and connections daily. Replace damaged

components immediately with BVA Hydraulics

replacement parts only.

3. Tighten connections as needed. Use non-hardening pipe

thread compound when servicing connections.

4. Check hydraulic oil level every 40 hours of operation. Add

hydraulic oil if necessary.

5. Completely change the hydraulic oil every 300 hours of

operation. Change the oil more frequently when pump is

used in an extremely dusty environment or when the oil has

been overheated. Use only good quality hydraulic oil. We

recommend BVA hydraulic oil (F01 & F05), Mobil DTE 15M

or equivalent. To order the oil, refer to service parts section.

Use

only the manufacturers recommended hydraulic oil.

Use of other hydraulic oil may result in pump failure

and will void warranty.

Adding Hydraulic Oil

1. Make sure electric motor is OFF.

2. Depressurize and disconnect hydraulic hose from

application.

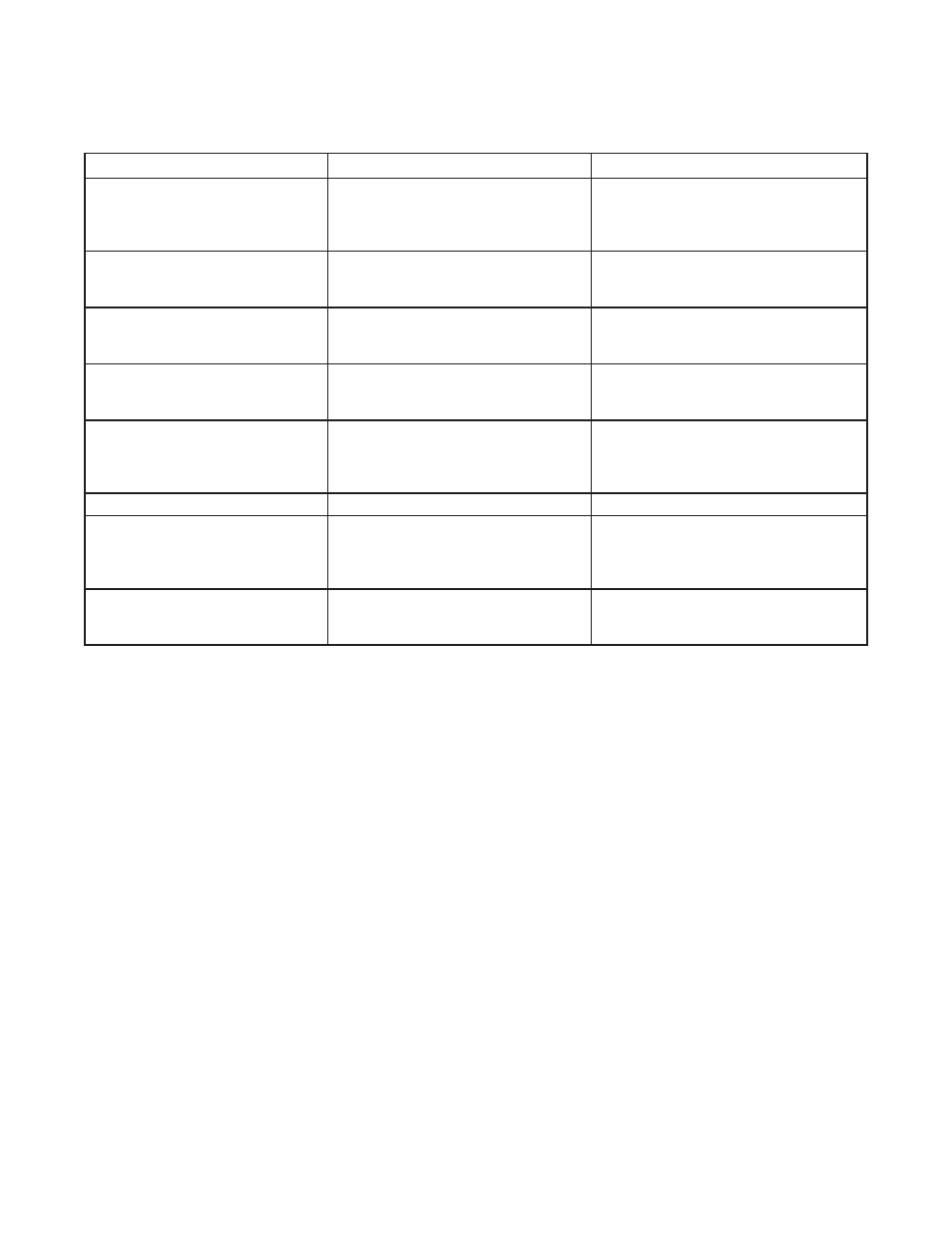

Symptom

Possible Causes

Corrective Action

Motor will not start

• No power or wrong voltage

• Damaged power cord

• Tripped circuit breaker

• Loose or faulty wiring

• Check the power supply & voltage

•

Contact Customer Service

•

Ensure electrical supply is adequate

•

Contact Customer Service

Erratic cylinder action

• Air in system or pump cavitation

• External leak

• Internal hydraulic leak

• Follow pump instructions for bleeding air

• Tighten all connections

• Contact Service Center

Pump fails to maintain

pressure

• External leak

• Internal hydraulic leak

• Pump or valve malfunction

• Tighten all connections

• Contact Service Center

Cylinder extends partially

•

Hydraulic oil level too low in pump

•

Load is above the capacity of system

•

Cylinder is sticking or binding

•

Fill and bleed the system

•

Use the correct equipment

•

Contact Service Center

Cylinder moves slower than normal

• Loose connection or coupler

• Restricted hydraulic line or fitting

• Pump not working correctly

• Cylinder seals leaking

• Tighten

• Clean and replace if damaged

• Check pump operating instructions

• Replace cylinder

Cylinder leaks hydraulic fluid

• Worn or damaged seals

• Replace cylinder

Cylinder will not retract or

retracts slower than normal

• Loose couplers

• Weak or broken retraction springs

• Cylinder damaged internally

• Pump reservoir too full

• Tighten couplers

• Replace cylinder

• Replace cylinder

• Drain hydraulic fluid to correct level

Motor cuts out

• Extension cord too long

• Faulty motor

• Overheated motor trips circuit breaker

• Replace

•

Replace or repair

•

Allow motor to cool, reset circuit breaker