Hydronic piping – Lochinvar 000 - 500 User Manual

Page 24

24

4

Hydronic piping

Installation & Service Manual

RELIEF VALVE

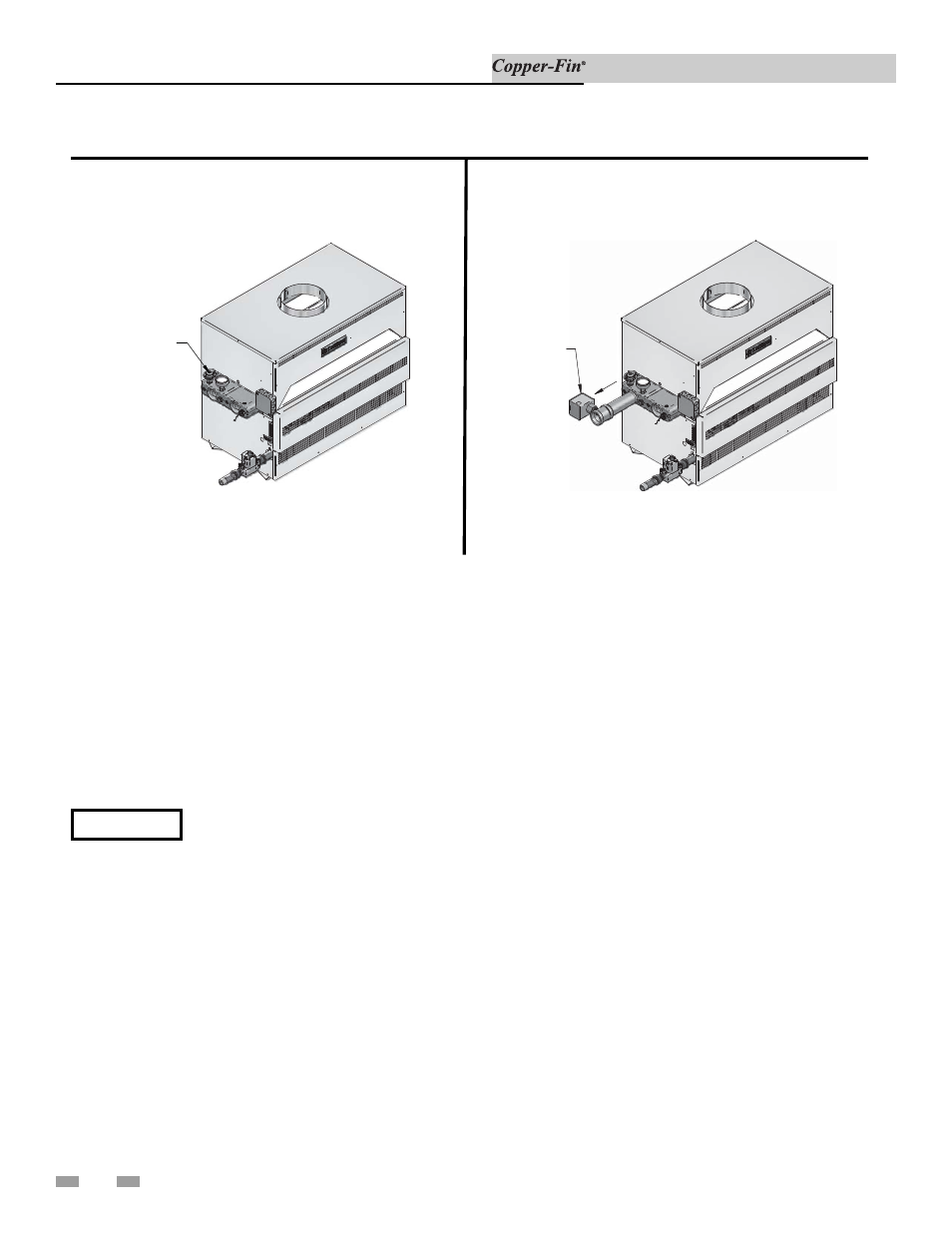

Figure 4-1_Relief Valve - CBN315-500

This appliance is supplied with a relief valve(s) sized in

accordance with ASME Boiler and Pressure Ves

sel Code,

Section IV (“Heating Boilers”). The re lief valve(s) is mounted

directly into the heat ex

chang

er inside the header (see

FIG.’s 4-1 and 4-2). To pre vent water damage, the dis charge

from the relief valve shall be piped to a suit able floor drain for

disposal when relief occurs. No reducing couplings or other

restrictions shall be installed in the discharge line. The

discharge line shall allow complete drainage of the valve and

line. Relief valves should be manually operated at least once a

year.

ƽ CAUTION

Avoid contact with hot discharge water.

FLOW SWITCH

Figure 4-2_Water Flow Switch - CBN315-500

A water flow switch is available as a factory sup plied option on

all heating boilers and water heaters (see section 7). The flow

switch should be wired between terminals X and B. Remove the

jumper between the X and B terminals on the terminal strip.

This wiring connection installs the flow switch in the 24 VAC

safety cir cuit to prove water flow before main burner ig ni tion. A

flow switch installed with the fac

to

ry sup

plied minimum

adjustment setting requires a spe cif ic minimum flow to make

the switch and start burner operation. The flow rate required is

a function of the diameter of pipe and tee used for installation.

Ensure that the pump installed on the boiler will supply

adequate flow to make the flow switch con tacts and operate the

appliance.

Relief Valve

Water Flow Switch (if equipped)