Micron Technology Turbofan User Manual

Page 17

DRAFT

16

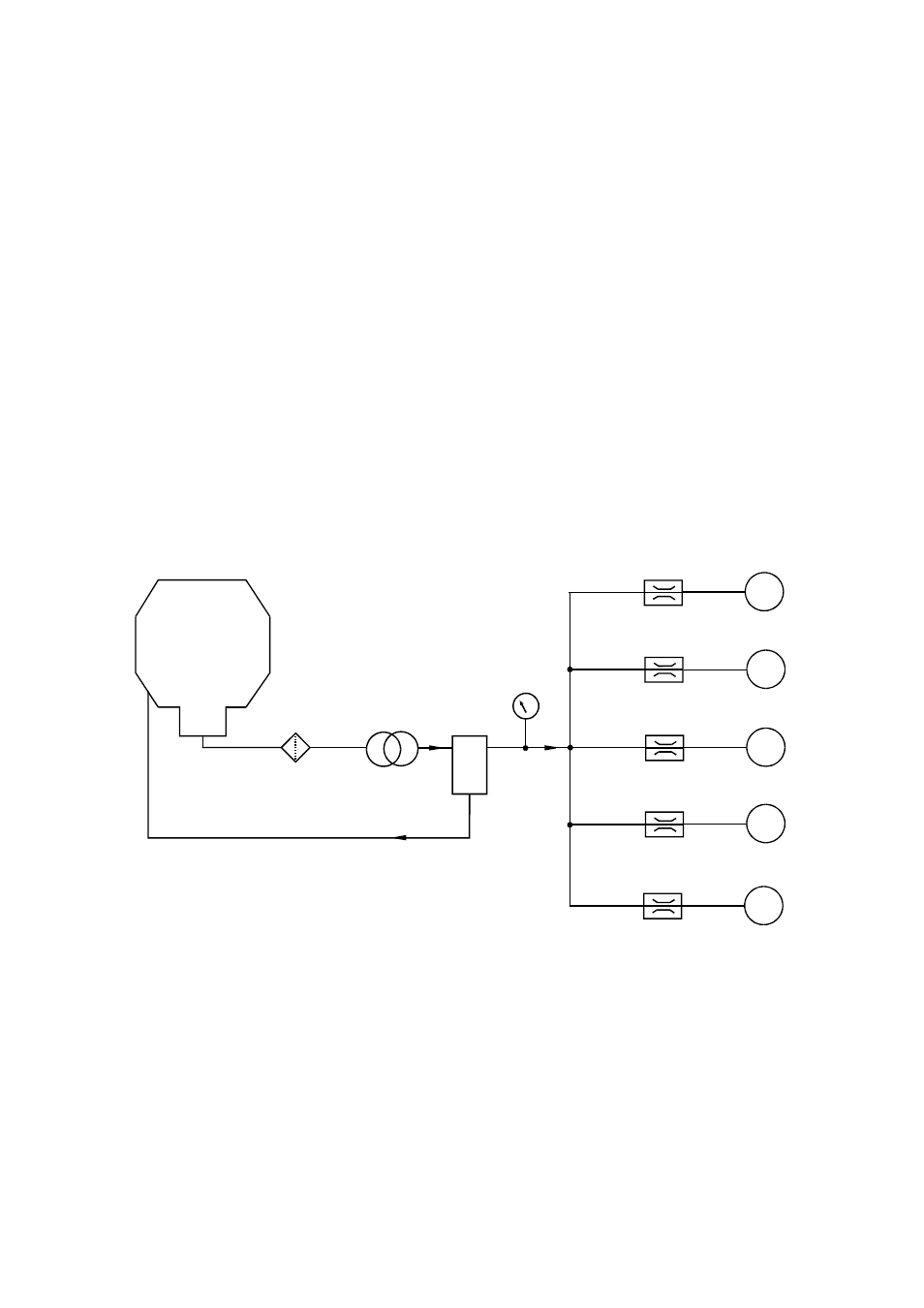

If a new sprayer is being designed or an original pump is to be replaced, it is suggested

that a diaphragm or centrifugal type is chosen. This should be able to provide a pressure

of about 1 – 3 bar (15 – 45 psi) and should be capable of delivering the maximum flow

rate of the sprayer plus the flow required for tank agitation (if a mechanical agitator is not

used). An output of 60 l/min is satisfactory for most low volume sprayers without

mechanical agitation.

A chemical on/off valve must be fitted in the main feed to the sprayheads. This may be

mechanically or solenoid operated. A multi-position valve can be used to select different

groups of sprayheads if required.

A filter must be incorporated in the chemical supply to the sprayheads. This should have

an 0.5 mm (50 mesh/inch) or finer mesh filter. The filter may be installed either in the

suction or pressure line of the pump but the filter must always be before the flow

restrictors and should preferably be before the pressure regulator. Fig 8 shows the

recommended chemical feed configuration for a typical sprayer.

Figure 8. Typical configuration of chemical feed to heads

SPRAY HEADS

FLOW

RESTRICTORS

PRESSURE

GAUGE

CHEMICAL

TANK

RETURN LINE TO AGITATOR

SUCTION STRAINER

CHEMICAL PUMP

ON/OFF AND

PRESSURE

CONTROL

VALVE