2control panel mounting specifications, Performance data, Fuel consumption data – Hobart Welding Products 000 User Manual

Page 2

2

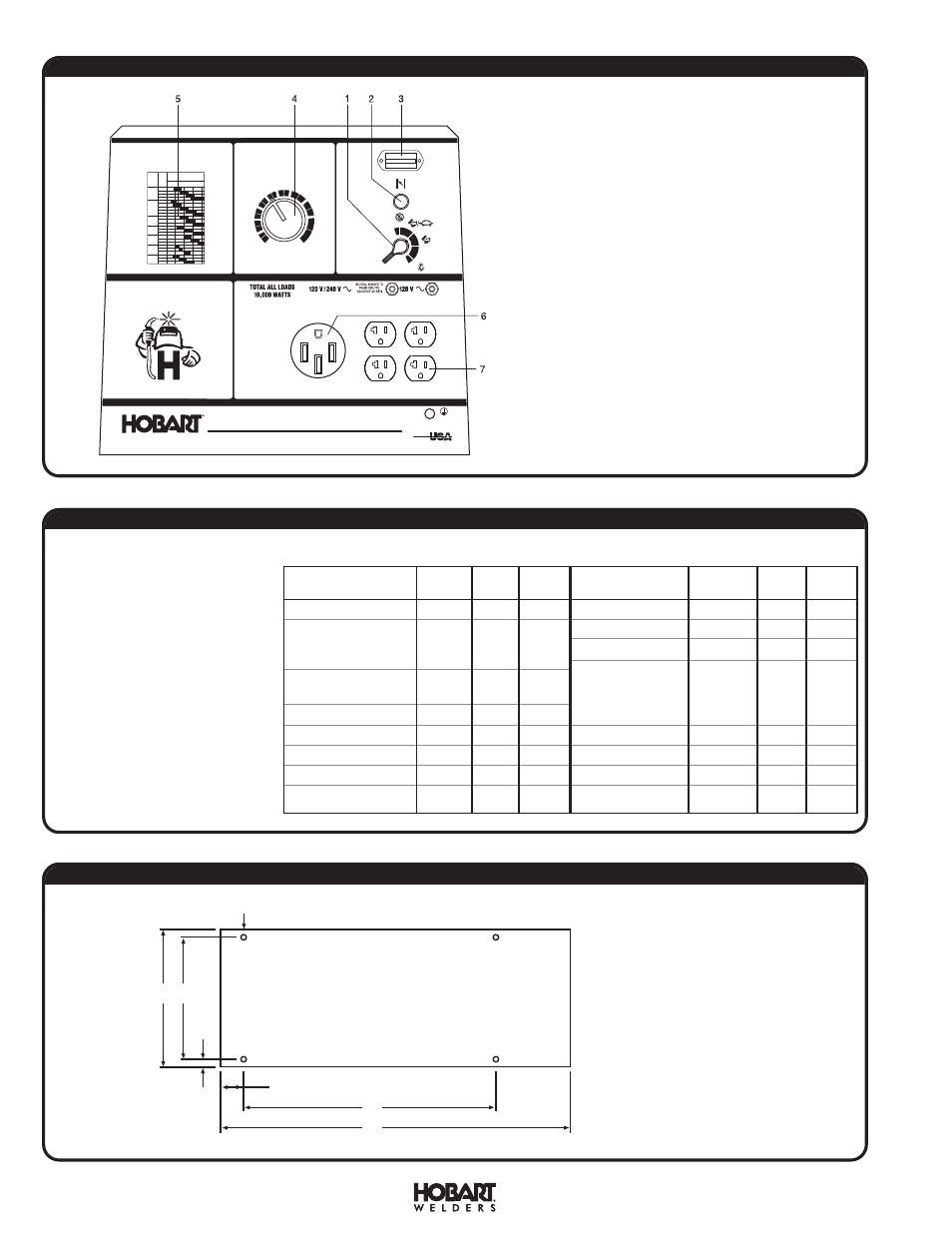

CONTROL PANEL

MOUNTING SPECIFICATIONS

1. Engine Control Switch allows for engine speed

selection. In Run/Idle position, engine runs at idle

speed at no load, and weld/power speed under load.

2. Engine Choke Control. Use control to change engine

air/fuel mix.

3. Engine Hour Meter. Combined with the Fastex “no

tools” oil change feature, routine service is easily

monitored and performed.

4. Amperage Control. Easy to set up for welding, and the

amperage control does not have to be turned up to

maximum to gain full auxiliary output.

5. Amperage Selection Chart. Explains weld settings for

typical electrode diameter sizes and types.

6. 120/240 Volt Receptacle. This versatile, 50-amp

circuit-breaker-protected receptacle can supply up to

10,000 watts of 230-volt power or, up to 10,000 watts of

120-volt power through two separate 120-volt circuits.

(Note: Protective covers not shown.)

7. 120 Volt Receptacle. Protected by two 20-amp

circuit breakers.

Champion 10,000

10,000-WATT AUXILIARY POWER GENERATOR • 230-AMP DC/CC WELDER

AMPERAGE ADJUST

ENGINE

AC POWER: TOTAL ALL LOADS 10,000 WATTS

MADE IN

GND/PE

120 V / 240 V

START

RUN

RUN / IDLE

OFF

CHOKE

3/32

1/8

5/32

3/16

5/64

3/32

1/8

5/32

3/16

3/32

1/8

5/32

3/32

1/8

5/32

3/32

1/8

5/32

3/32

1/8

5/32

3/32

1/8

5/32

ELECTRODE

DIAMETER

50

10

0

15

0

200

AMPERAGE

RANGE

6010

&

6011

6013

7014

7018

7024

Ni-Cl

308L

MAX

MIN

80

100

120

140

160

180

200

220

PERFORMANCE DATA

Fuel Consumption Data

The Champion 10,000 offers modern, fuel

efficient engines from Robin or Kohler. With

the OHV design, automatic idle and 10 gallon

fuel tank, you can expect to put in long hours

before having to stop and refuel. For example:

• Welding at 125 amps, 100% duty cycle,

uses about 1 gal of fuel every hour.

• While not welding, the engine drops to idle

speed using about 1/2 gal of fuel every hour.

• On a typical job using 1/8-in 7018 electrodes

(125 amps, 20% duty cycle) you can expect

over 16 hours of operation.

• Under a continuous load of 4,000 watts

of auxiliary power, the Champion 10,000

would run for about 9 hours.

A. 18 in (457 mm)

B. 16-9/16 in (421 mm)

C. 3/4 in (19 mm)

D. 3 in (76 mm)

E. 31-1/2 in (800 mm)

F. 37-1/2 in (953 mm)

G. 13/32 in (10 mm) Diameter

4 Holes

Engine End

G

A

B

C

D

E

F

Typical Power Requirements for Farm, Home and Contractor Equipment

Rating

14 in

1-1/2 HP

2 HP, 14 in

HID

Metal Halide

Mercury

Vapor

400 gph

900 gph

1 HP

1.7 HP

Equipment

Band Saw

Air Compressor

Electric Chain Saw

Flood Lights

Submersible Pump

Centrifugal Pump

High Pressure Washer

Wet & Dry Vac

Starting

Watts

2500

8200

1100

125

313

1000

1250

600

900

6100

900

Running

Watts

1100

2200

1100

100

250

—

1000

200

500

1600

900

Rating

1/2 HP

1/3 HP

1-1/2 HP

550 PSI

700 PSI

1/3 HP

1/2 HP

1/2 in

8-1/4 in

10 in

Starting

Watts

3400

1720

8200

4500

6100

2150

3200

600

1400

6300

Running

Watts

1000

720

2200

1400

1600

750

1050

600

1400

1800

Equipment

Portable Conveyor

Farm-Duty Motors Std.,

(e.g. Conveyors, Feed

Augers, Air Compressors)

Washer 2 gal/min

2 gal/min

Refrigerator or Freezer

Sump Pump

Hand Drill

Circular Saw

Table Saw