Harbor Freight Tools 42696 User Manual

Page 6

Bleeding the System

If any air becomes trapped in the system during initial connections or at a later time, the following steps should

be taken to bleed the system.

Note: Air in the system will cause the ram to rise and fall as the handle is pumped. If the ram does not fully

extend, add oil through the Filler Plug (#33B).

Step 1)

Place the Jack Handle (#19A) on the Release Valve. Open the Release Valve (#4B) by turning

the Jack Handle (#19A) counterclockwise.

Step 2)

Open the Filler Plug (#33B) on the side of the jack.

Step 3)

Pump the Jack Handle (#19A) rapidly several times.

Step 4)

Close the Release Valve (#4B) by turning the Jack Handle (#19) fully clockwise. Test the

function of the jack, and repeat, if necessary.

Step 5)

Replace the Filler Plug (#33B).

Caution:

When not in use, make sure pressure is released by turning the Jack Handle fully

counterclockwise. This will prolong the life of the Log Splitter.

Operating the Log Splitter

Note:

Make sure the Release Valve (#4B) is turned fully clockwise to the closed position.

Step 1)

Make certain that the maximum length of each log to be split does not exceed

27". If the log exceeds this length, it must be cut to no longer than 27". The logs

diameter is not to exceed 8".

Step 2)

Place the Log between the Jack Support (#1A) and the Blade Assembly (#4A).

Step 3)

Insert the Jack Handle (#19A) into the Handle Sleeve (#27B)-see Figure 2. The Jack

Handle must fit into the Handle Sleeve (#27B) firmly. Turn the Jack Handle (#19A)

until you feel it slide securely into place.

Step 4)

Pumping the Jack Handle (#19A) up and down will raise the Jack Support up to the Blade

Assembly (4A) until the log is split.

Warning: Keep clear of the area surrounding the log while it is being split. Be alert to falling sections

of the log as it is split. Keep spectators well clear of the work area while the Log Splitter is being used.

Step 5)

Once the Log is split, slowly release the Release Valve (#4B) by turning counterclockwise

and remove the pieces from the Log Splitter. To back the Blade Assembly (#4A) off of the log,

turn the Jack Handle (#19A) counterclockwise. This will release the pressure and lower the

Hydraulic Jack.

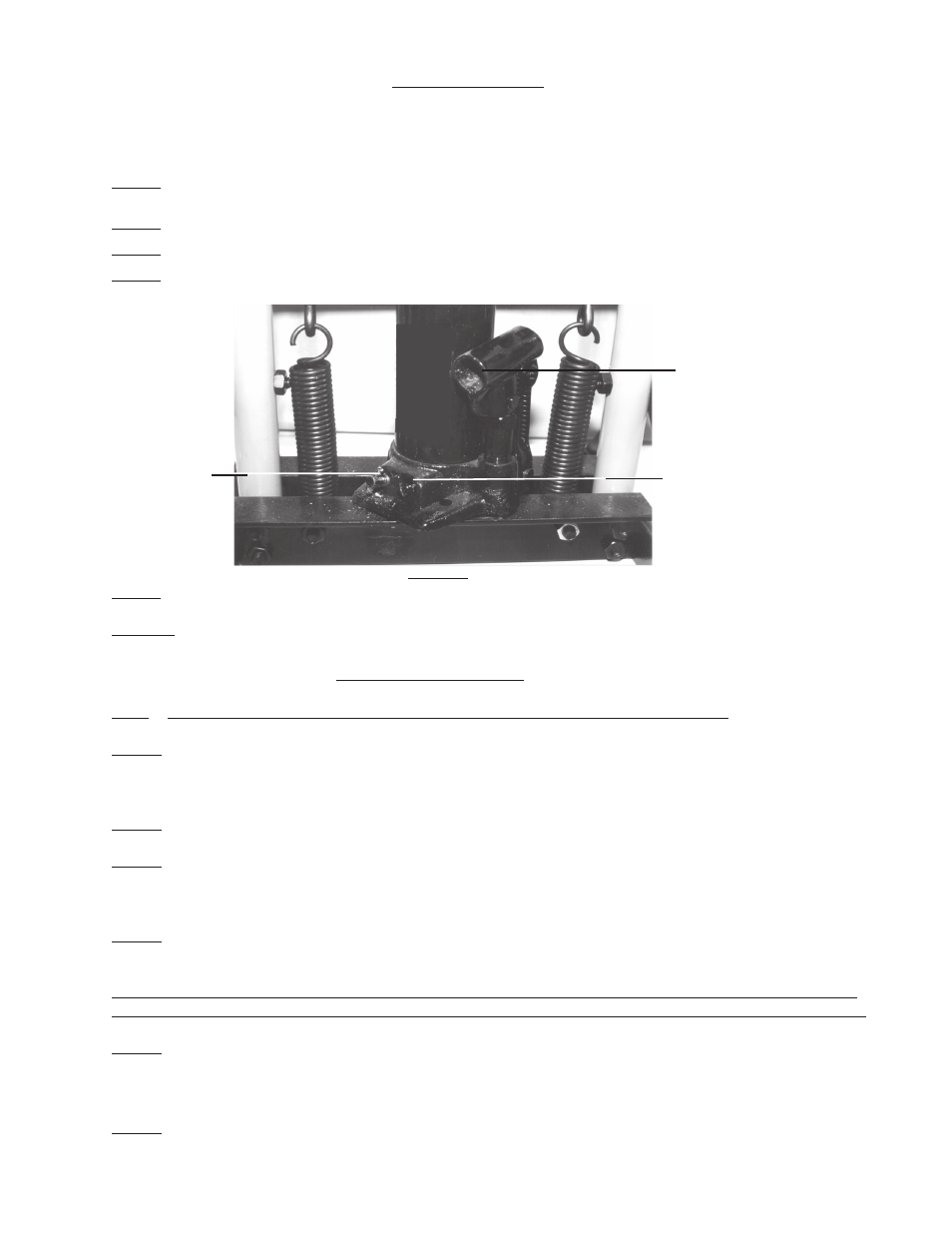

Release

Valve (#4B)

Plastic Cap

Safety Valve (#10B)

Handle Sleeve (#27B)

#42696

Page 6

Figure 2

Step 6)

Continue the preceding steps until all logs have been split.

(DO NOT ADJUST)