Troubleshooting – Hilti TE 7-C User Manual

Page 14

The outer casing of the power tool is made from

impact-resistant plastic. Sections of the grip are made

from a synthetic rubber material.

Never operate the power tool when the ventilation

slots are blocked. Clean the ventilation slots carefully

using a dry brush. Do not permit foreign objects to

enter the interior of the power tool. Clean the outside

of the power tool at regular intervals with a slightly

damp cloth. Do not use a spray, steam pressure

cleaning equipment or running water for cleaning.

This may negatively affect the electrical safety of the

power tool.

8.3 Cleaning or replacing the dust shield

Clean the dust shield on the chuck with a dry, clean

cloth at regular intervals. Clean the sealing lip by

wiping it carefully and then grease it again lightly

with Hilti grease. It is essential that the dust shield

is replaced if the sealing lip is found to be damaged.

Push the tip of a screwdriver under the edge of the

dust shield and prise it out toward the front. Clean

the area of the chuck in contact with dust shield and

then fit a new dust shield. Press it in firmly until it

engages.

8.4 Maintenance

WARNING

Repairs to the electrical section of the power tool

may be carried out only by trained electrical spe-

cialists.

Check all external parts of the power tool for damage

at regular intervals and check that all controls operate

faultlessly. Do not operate the power tool if parts

are damaged or when the controls do not function

faultlessly. If necessary, the power tool should be

repaired by Hilti Service.

8.5 Checking the power tool after care and

maintenance

After carrying out care and maintenance work on

the power tool, check that all protective and safety

devices are fitted and that they function faultlessly.

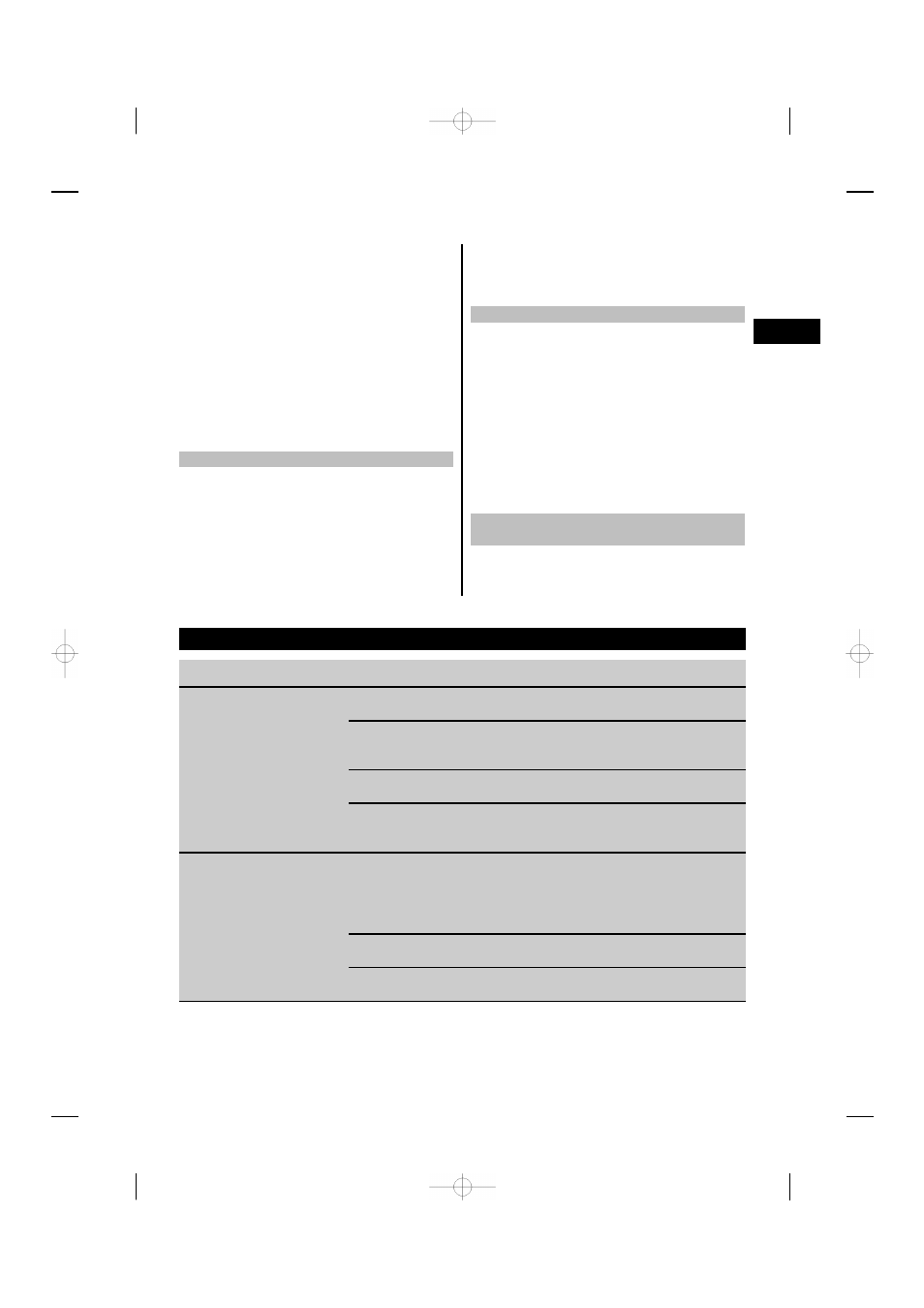

9. Troubleshooting

Fault

Possible cause

Remedy

The power tool doesn’t start.

Interruption in the electric supply.

Plug in another electric appliance

and check whether it works.

Supply cord or plug defective.

Have the supply cord and plug

checked by a trained electrical spe-

cialist and replaced if necessary.

Other electrical fault.

Have it checked by a trained elec-

trical specialist.

The carbon brushes are worn.

Have the supply cord and plug

checked by a trained electrical spe-

cialist and replaced if necessary.

No hammering action.

The power tool is too cold.

Allow the power tool to warm up to

the minimum operating temperat-

ure.

See section: 7.2.1 Working at low

temperatures

The function selector switch is set

to “Drilling without hammering”.

Set the function selector switch to

“Hammer drilling”.

The forward/reverse switch is set

to reverse rotation.

Set the forward/reverse switch to

forward rotation.

en

11