Harbor Freight Tools 42933 User Manual

Page 12

SKU 42933

For replacement parts, please call 1-800-444-3353.

Page 12

Bevel Cross Cutting

1.

Loosen the Bevel Lock Knob (71) and pull out the Bevel Index

Knob (74).

2.

Turn the motor assembly clockwise or counterclockwise,

selecting the desired angle (variable or indexed, i.e., 45

degrees).

3.

Tighten the Bevel Lock Knob (71) and push in the Bevel Index Knob (74).

4.

Push the Handle backward so that the Saw Blade is in behind the stock to be cut.

5.

Secure the stock to be cut against the table and fence. If the stock length is short, do

not hold with your hand. Use a clamp to hold in place.

6.

Adjust the Anti-kickback Arm (15) so it just clears the stock.

7.

Press the green Switch (122). Squeeze the Trigger and push the Handle all the way

back.

8.

When the cut is complete, release the Trigger and push the Handle all the way back.

Compound Cross Cutting

Compound crosscutting combines the mitre and bevel functions. Set the Saw Blade angles

as previously described. Continue to follow steps 4 through 9, above.

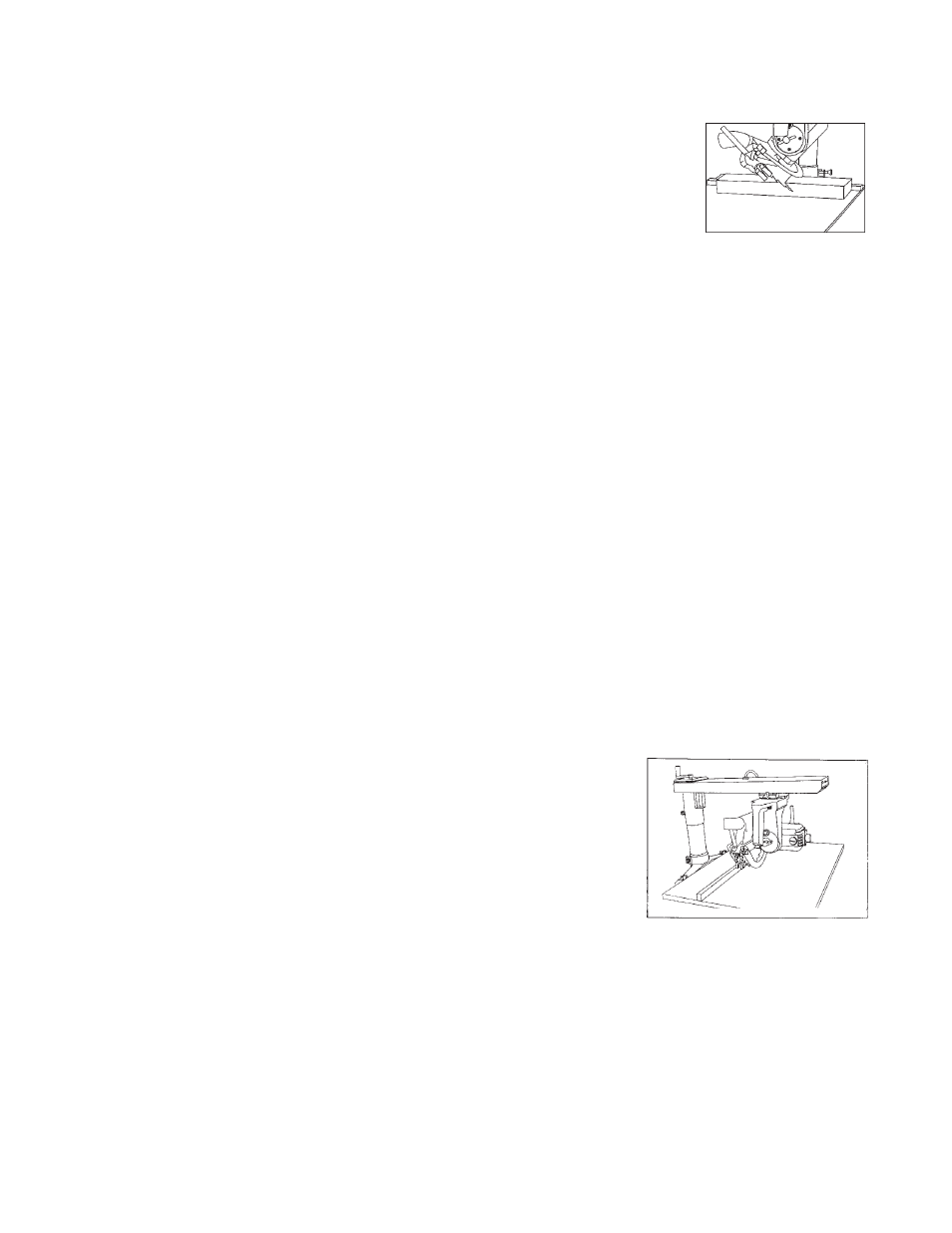

In-Rip Cutting

Ripping is the process of cutting stock along the grain (or lengthwise). The stock if fed into

the Saw Blade against the blade rotation (similar to a table saw). The fence is used as a

guide to help maintain cutting width.

1.

Loosen the yoke Clamp Handle (66) and pull out the

Yoke Index Knob.

2.

Turn the motor assembly to the left and lock the Yoke

Index Knob at 90 degrees.

3.

Tighten the yoke Clamp Handle (66).

4.

Adjust the Saw Blade Safety Guard (7) so it is just above

the surface of the stock to be ripped.

5.

Adjust the Anti-kickback Arm (13) so it is just above the

stock surface.

6.

Adjust the Carriage Arm so that the Saw Blade is at the desired depth for the rip cut,

and securely lock the Carriage Lock Knob in place.

Note that the larger portion of the stock being ripped should be between the Fence

and the Saw Blade.

7.

Adjust the Elevating Handle (100) so that the Saw Blade is 1/16 inch into the worktable.

8.

Verify that the Bevel Index Knob is locked into 0 degrees.