Notice, Air supply maintenance, Storage – Harbor Freight Tools 66103 User Manual

Page 13: General troubleshooting chart

Page 13

For technical questions, please call 1-800-444-3353.

Item 66103

NOTICE

Clean the Spray Gun IMMEDIATELY after use.

Delayed or inadequate cleaning will permanently clog the Spray Gun.

SAFETY

Op

ERA

TION

M

AINTENANCE

SETU

p

7. Use appropriate solvent

(see

Solvent Selection, left)

to wipe down Spray Gun body.

8. Lubricate Spray Gun after cleaning.

A non-silicon oil or a light lubricant may be

used on threaded connections before storing.

Solution Disposal

After cleaning, dispose of cleaning solution

according to the solution manufacturer’s

directions and local hazardous waste standards.

Air Supply Maintenance

Every day, perform maintenance on the air supply according

to the component manufacturers’ instructions.

Storage

Store in a dry, secure area out of reach of children.

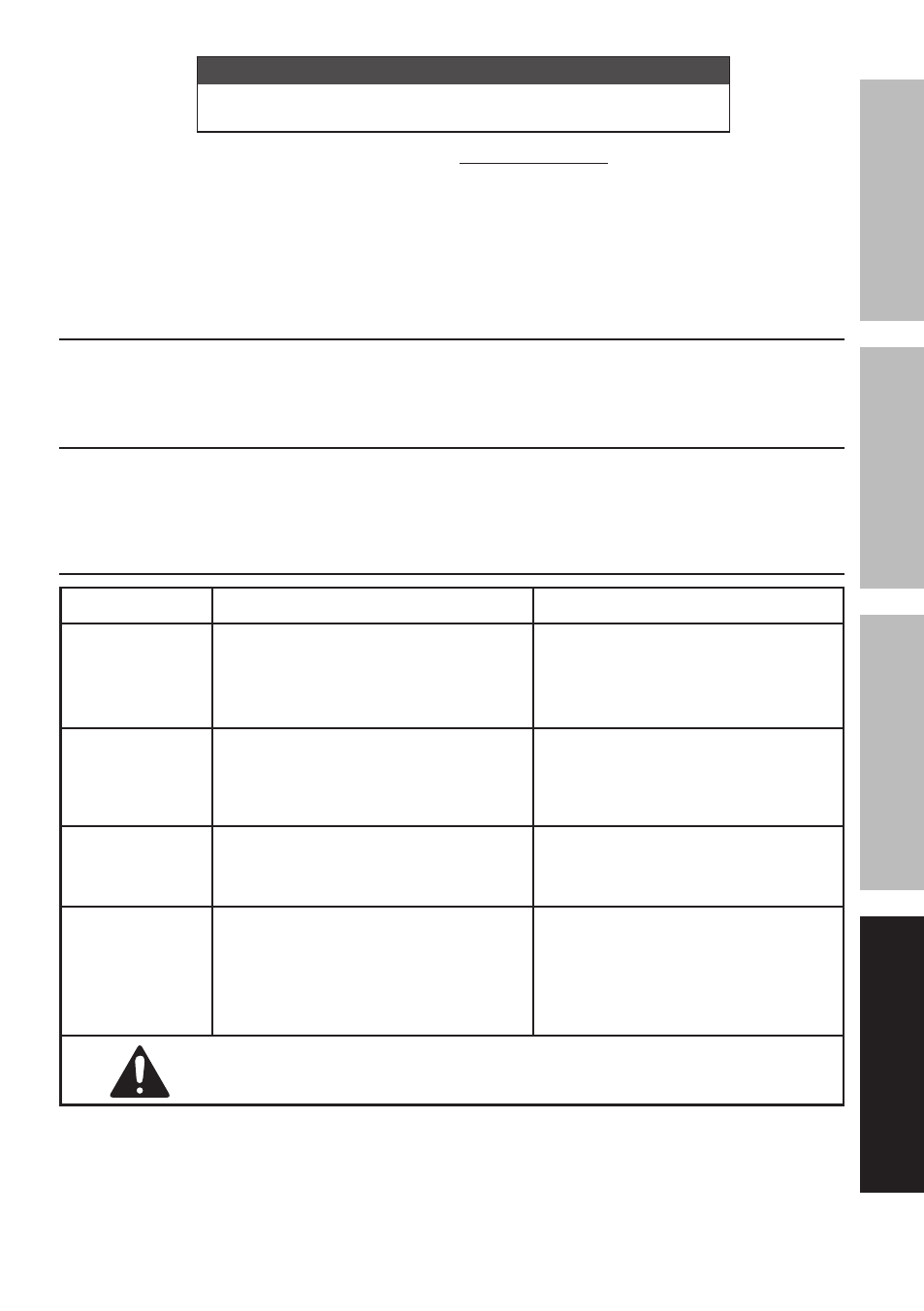

General Troubleshooting Chart

problem

possible Causes

Likely Solutions

Sputtering Spray 1. Low coating level.

2. Clogged Air Vent.

3. Loose fluid inlet connection.

4. Loose/damaged fluid tip/seat.

1. Refill.

2. Clean Air Vent hole.

3. Tighten fluid inlet connection.

4. Adjust or replace fluid tip.

Will Not Spray

1. No pressure at Spray Gun.

2. Fluid Knob not open enough.

3. Fluid too thick.

1. Check air hoses.

2. Open Fluid Knob.

3. Thin fluid or increase air pressure.

(Do not exceed maximum.)

Fluid Tip

Leakage

1. Dirty tip.

2. Broken fluid needle spring.

3. Worn or damaged tip.

1. Clean tip.

2. Replace fluid needle spring.

3. Replace tip and/or needle.

Air Leaking

from Nozzle

1. Dirty air valve/seat.

2. Sticking air valve.

3. Damaged air valve spring.

4. Worn/damaged air valve/seat.

5. Bent valve stem.

1. Clean air valve/seat.

2. Lubricate air valve/seat.

3. Replace air valve spring.

4. Replace air valve.

5. Replace valve stem.

Follow all safety precautions whenever diagnosing or servicing the tool.

Disconnect air supply before service.