Vent clearances and framing, A. pipe clearances to combustibles, B. wall penetration framing – Heat & Glo Fireplace Heat & Glo 6000GL-IPI-R User Manual

Page 33

Heat & Glo • 6000GL-IPI-R, 6000GL-IPI-S • 2102-900 Rev. R • 6/09

33

A. Pipe Clearances to Combustibles

WARNING! Risk of Fire! Maintain air space clearance to

vent. DO NOT pack insulation or other combustibles:

• Between ceiling fi restops

• Between wall shield fi restops

• Around vent system

Failure to keep insulation or other material away from

vent pipe may cause over heating and fi re.

8

8

Vent Clearances and Framing

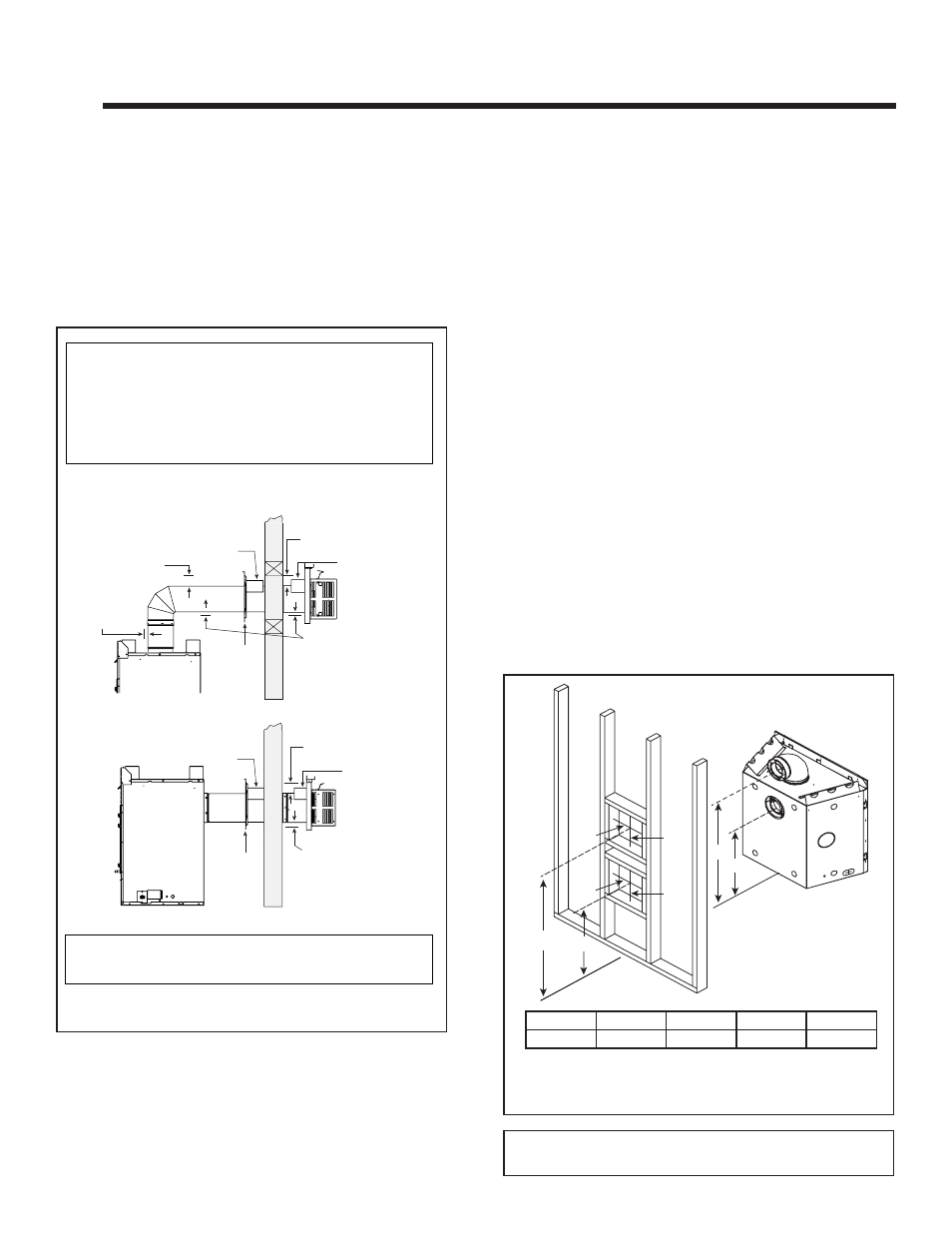

Figure 8.1 Horizontal Venting Clearances To Combustible

Materials

* When using SLP or SL-D pipe, minimum clearances from the vent pipe to combus-

tible materials at inside wall firestops are: Top: 2-1/2 in. (64 mm)

Bottom: 1/2 in. (13 mm)

Sides: 1 in. (25 mm)

Note: Heat shields MUST overlap by a minimum of 1-1/2 in. (38 mm).

• DVP heat shield - designed to be used on a wall 4 in. to 7-1/4 in. (102 mm to 184

mm) thick.

• If wall thickness is less than 4 in. the existing heat shields must be field trimmed. If

wall thickness is greater than 7-1/4 in. a DVP-HSM-B will be required.

• SLP heat shield - designed to be used on a wall 4-3/8 in. to 7-5/8 in. (111 mm to

194 mm thick).

• If wall thickness is less than 4-3/8 the existing heat shields must be field trimmed.

If wall thickness is greater than 7-5/8 in. a DVP-HSM-B will be required.

(DVP-SLP Pipe Shown)

3 in. (76 mm)

top clearance *

1 in. (25 mm)

clearance

bottom & sides

Heat

Shield

Wall

Shield

Firestop

Heat

Shield

WALL

3 in. (76 mm)

top clearance *

1 in. (25 mm)

clearance

bottom & sides

Heat

Shield

Wall

Shield

Firestop

Heat

Shield

WALL

3 in. (76 mm)

top clearance

1 in. (25 mm)

clearance around

vertical sections

A*

B*

10 in.

12 in.

C

D

10 in.

12 in.

Figure 8.2 Wall Penetration

* Shows center of vent framing hole for top or rear venting. The center of the

hole is one (1) in. (25.4 mm) above the center of the horizontal vent pipe.

A*

B*

C

D

Inches

42-3/4

27-7/8

41-3/4

26-7/8

B. Wall Penetration Framing

Combustible Wall Penetration

Whenever a combustible wall is penetrated, you must

frame a hole for the wall shield fi restop(s). The wall shield

fi restop maintains minimum clearances and prevents cold

air infi ltration.

• The opening must be framed on all four sides using the

same size framing materials as those used in the wall

construction.

• SLP pipe - A wall shield fi restop must be placed on each

side of an interior wall. A minimum 1-1/2 in. (38 mm)

overlap of attached heat shields must be maintained.

• DVP pipe - A wall shield fi restop is required on one side

only on interior walls. If your local inspector requires a

wall shield fi restop on both sides, then both wall shield

fi restops must have a heat shield (refer to Section 16.B.)

attached to them.

• See Section 10.M. for information for regarding the in-

stallation of a horizontal termination cap.

Non-Combustible Wall Penetration

If the hole being penetrated is surrounded by noncom-

bustible materials such as concrete, a hole with diameter

one inch greater than the pipe is acceptable.

Whenever a non-combustible wall is penetrated, the wall

shield fi restop is only required on one side and no heat

shield is necessary.

Note: When terminating horizontally off the top of the unit

using SLP pipe, a 10 in. x 10 in. framing hole is required.