Locating the water pump, Safety opera tion maintenance setup – Harbor Freight Tools Pacific Hydrostar 212cc Gasoline Powered Clear Water Pump 69774 User Manual

Page 9

Page 9

For technical questions, please call 1-800-520-0882.

ITEM 69774

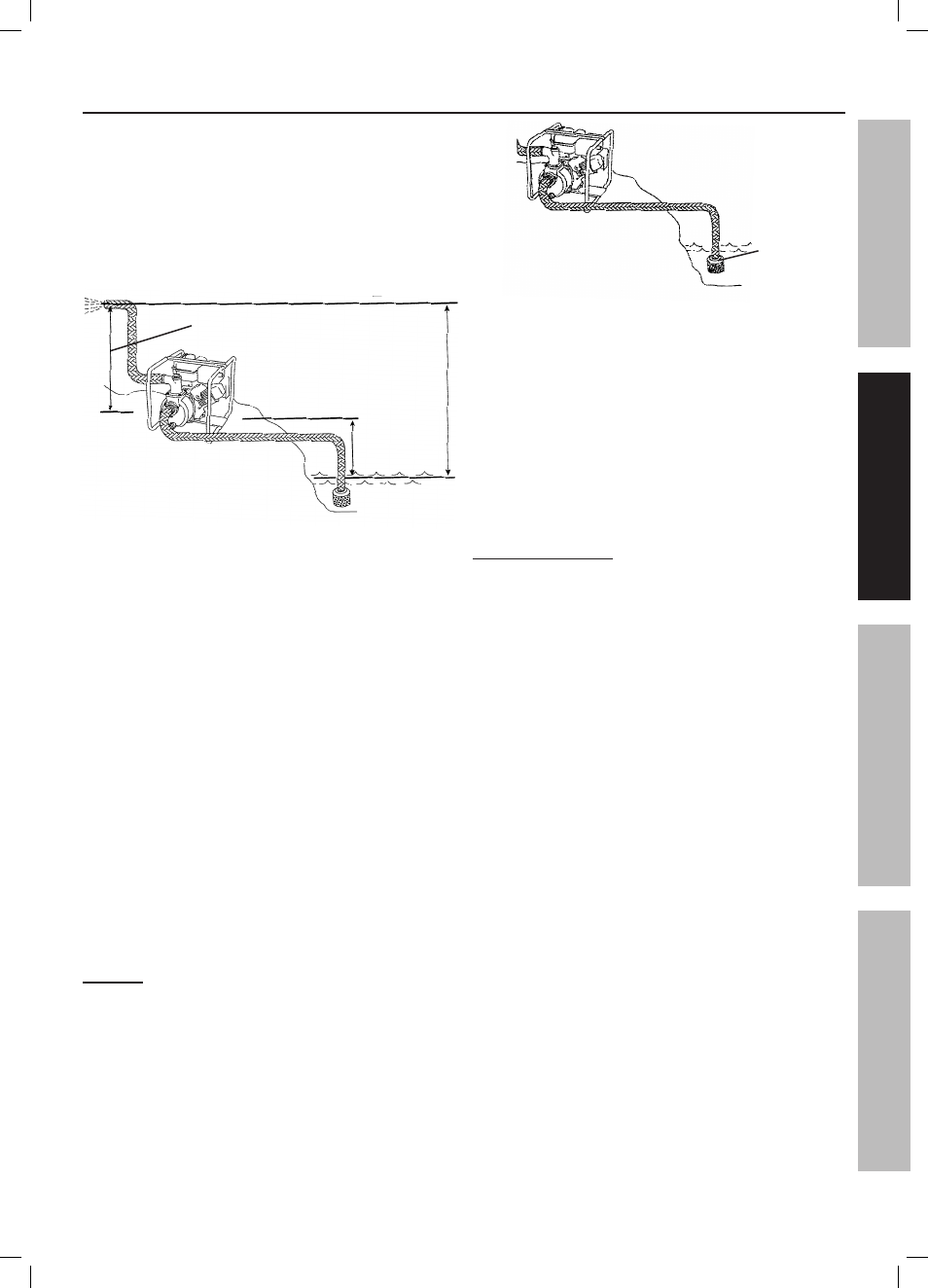

Locating the Water Pump

Locate the Water Pump on a flat, level, sturdy surface

capable of supporting the weight of the Pump.

1. For best Pump performance, place the Pump near

the water level and use hoses that are no longer

than necessary. This will allow the Pump to produce

the greatest output with the least self‑priming time.

See diagram below.

Total Head

Suction

Head

Water Pump

Discharge Head

As the head (pumping height) increases, pump

output decreases. The length, type, and size of the

suction and discharge hoses can also significantly

affect Pump output.

Discharge head capability is always greater than

suction head capability. This means pumping height

for the Intake Hose (suction head) should be shorter

than the pumping height for the Discharge Hose.

Minimizing suction head (placing the Pump

closer to the water level) will also help reduce

self‑priming time. This is the time it takes the

Pump to bring the water from the water level

to the Pump during the initial operation.

2. Route the Intake Hose with the Intake Strainer

fully immersed in the water supply source.

3. Place Strainer into water to be pumped.

CAUTION: Immerse strainer fully in water.

Do not operate Pump without Strainer connected

to end of suction hose. Keep Strainer out of sand

or silt by placing Strainer in a bucket or on stones.

NOTICE: If there is an air leak in the suction line,

you may not be able to prime the pump.

Use of a thread sealant is recommended.

4.

Strainer

Secure the Intake Hose in place to keep it

from moving once the Pump is turned on.

The Intake Hose should be as short as

possible for more efficient operation.

5. Route the discharge hose to the desired discharge

location. If necessary, connect additional discharge

hoses to direct the discharge to the desired location.

Make sure to secure the discharge hose in place

to keep it from moving once the Water Pump is

turned on. The discharge hose should be kept as

short as possible for more efficient operation.

Operation Concerns

1.

CAVITATION: This is the sudden formation and

collapse of low‑pressure vapor (bubbles) across the

vanes of the impeller.

Cause: When the surface pressure on a liquid

becomes low enough, the liquid will begin to boil

(even at room temperature). With centrifugal pumps,

cavitation can occur when the suction vacuum

becomes too great, allowing water vapor or bubbles

to form at the impeller. The rapid pressure increase

can cause impeller damage.

Solution: Minimizing suction head and using

the largest practical suction hose diameter will

reduce the likelihood of cavitation.

Do not use

a suction hose with a diameter smaller than

the Pump’s Intake Port (2″ diameter).

2.

WATER HAMMER PRESSURE: This is energy sent

back to the Pump due to sudden stoppage of water

flowing from the Pump.

Cause: Water hammer pressure is more likely to

occur when using a very long discharge hose. If the

flow of water at the end of the discharge hose is shut

off suddenly, energy is sent back to the pump. This

causes a large pressure spike in the Pump housing,

leading to potential damage to the Pump casing.

Solution: Use as short a discharge hose as possible

and

turn off water pump before closing water flow.

SAFETY

OPERA

TION

MAINTENANCE

SETUP