Notice – Harbor Freight Tools CENTRAL PNEUMATIC 94572 User Manual

Page 11

Page 11

For technical questions, please call 1-800-444-3353.

Item 94572

NOTICE

Clean the Spray Gun IMMEDIATELY after use.

Delayed or inadequate cleaning will permanently clog the Spray Gun.

SAFETY

Op

ERA

TION

M

AINTENANCE

SETU

p

6. Test the consistency by spraying

on a piece of scrap material.

If it still appears too thick, add a very small

amount of thinner (not included)and mix

thoroughly. Use the proper thinner for

the type of paint. Thin CAUTIOUSLY.

Proceed slowly, adding minimal

amounts at a time.

DO NOT exceed the

manufacturer’s thinning recommendations.

Fan Direction

7.

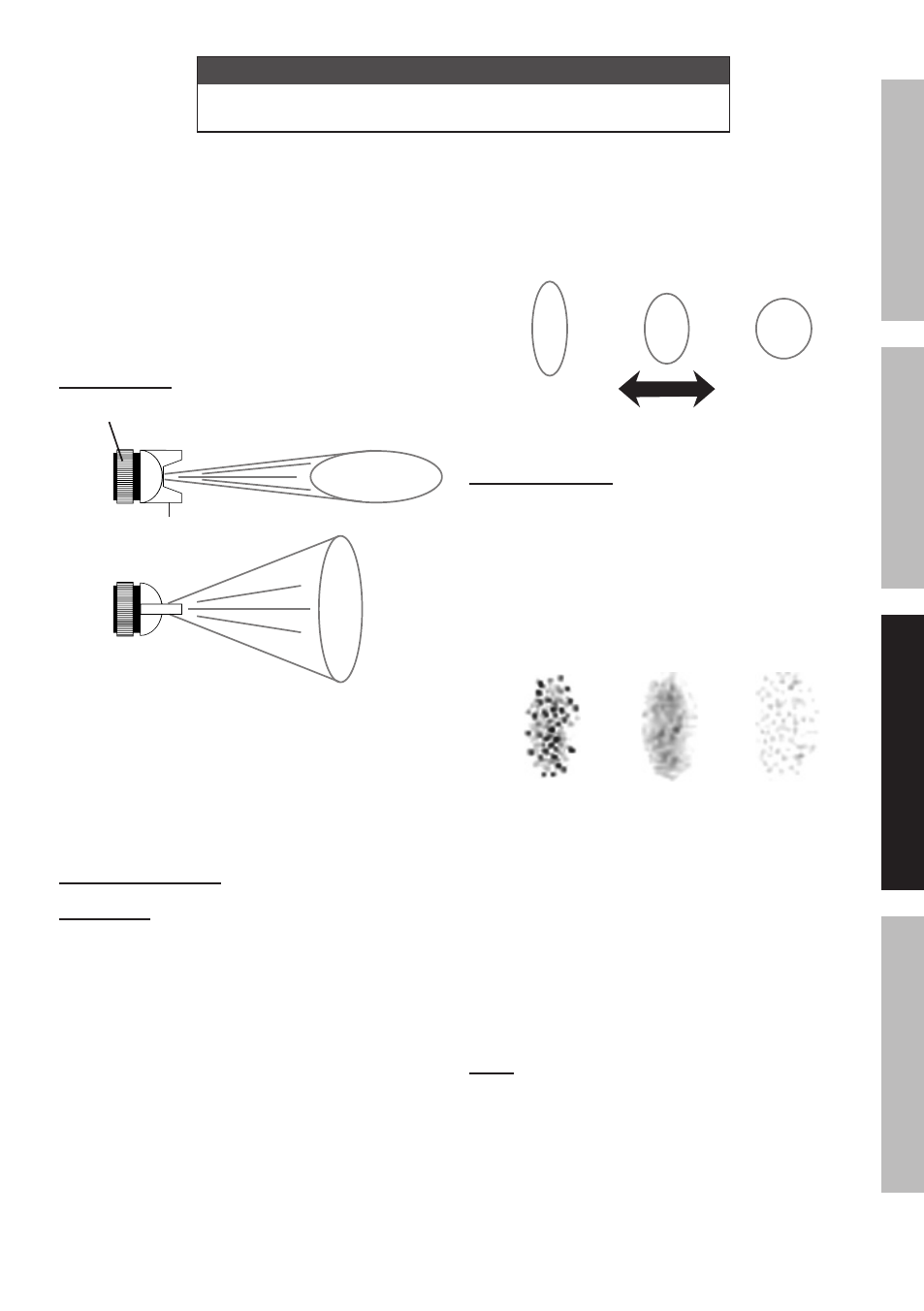

Figure D: Fan Direction

Horizontal Fan

Vertical

Fan

Nozzle

Lock Ring

To change the direction of the

fan from horizontal to vertical,

loosen the Lock Ring and turn the Nozzle 90°.

8. After the adjustment, tighten

the Lock Ring by hand.

pattern Adjustment

WARNING! Do not exceed the Maximum Air

pressure shown on the Specification chart.

9. Adjust the air supply pressure during

operation with the Trigger fully depressed and

the Air Knob fully open.

If reducing air pressure for specific areas,

use the Air Knob.

10. Use the Pattern Knob to

adjust the spray pattern.

Turn Pattern Knob counterclockwise

(all the way open) to flatten the spray pattern.

Turn it clockwise for a round spray pattern

- see Figure E: Pattern Adjustment.

Figure E: pattern Adjustment

Flat/

Open

Round/

Closed

Fluid Adjustment

11. Turn the Fluid Knob clockwise

until it is fully closed.

12. After setting up a piece of scrap

material, squeeze the Trigger in short

bursts while turning the Fluid Knob

counterclockwise to set the amount of fluid

- see Figure F: Fluid Adjustment.

Too Fine

(Decrease

air flow)

Too Coarse

(Increase

air flow)

Correct

Figure F: Fluid Adjustment

If spray is too fine:

Reduce the air pressure or allow more paint

to come out by opening the Fluid Knob.

If spray is too thick (globs of paint):

Close the Fluid Knob slowly,

checking the pattern after each adjustment.

Note: Change nozzle and needle size

according to the thickness and type of paint

being used. Generally, larger diameter nozzles

are more suitable for thicker paints.