Settings and adjustments – Harbor Freight Tools 38119 User Manual

Page 11

SKU 38119

For technical questions, please call 1-800-444-3353.

Page 11

Ensuring all parts are thoroughly clean and dry and burr free, place the chuck over

4.

the end of the spindle, and pull the spindle down using the feed handles, pressing

the chuck jaws hard against the piece of scrap wood until the chuck is forced

home.

Pulley cover knob

Locate the knob with pan head screw and attach to the cover.

1.

Screw on tightly.

2.

adjusting the Drive belt

The drive belt is pre-installed. However, if the belt requires tightening or the

spindle speed needs to be changed, proceed with the following steps:

Undo the Belt Tension Locking Screw to loosen the belt.

1.

Consult the chart inside the pulley cover (or the Drill Speed chart in this manual),

2.

and install the belt in the position corresponding to spindle/drill speed required.

Lever the motor, on its bracket, away from the head, so that tension is applied

3.

to the belt. Tension is correct when the belt deflects by approximately 1/2” at its

center when using reasonable thumb pressure. Lock the motor in this position

using the locking screw.

note: If the belt slips during operation, adjust the belt tension.

SEttIngS anD aDjuStMEntS

before adjustments are made, ensure that the machine is

SWITCHED OFF AND UNPLUGGED. Also make sure

all locking handles and securing screws are FULLY

TIGHTENED when adjustments are completed.

WaRnIng! tO PREVEnt SERIOuS InjuRY:

Secure the drill press to the bench or table top

before using.

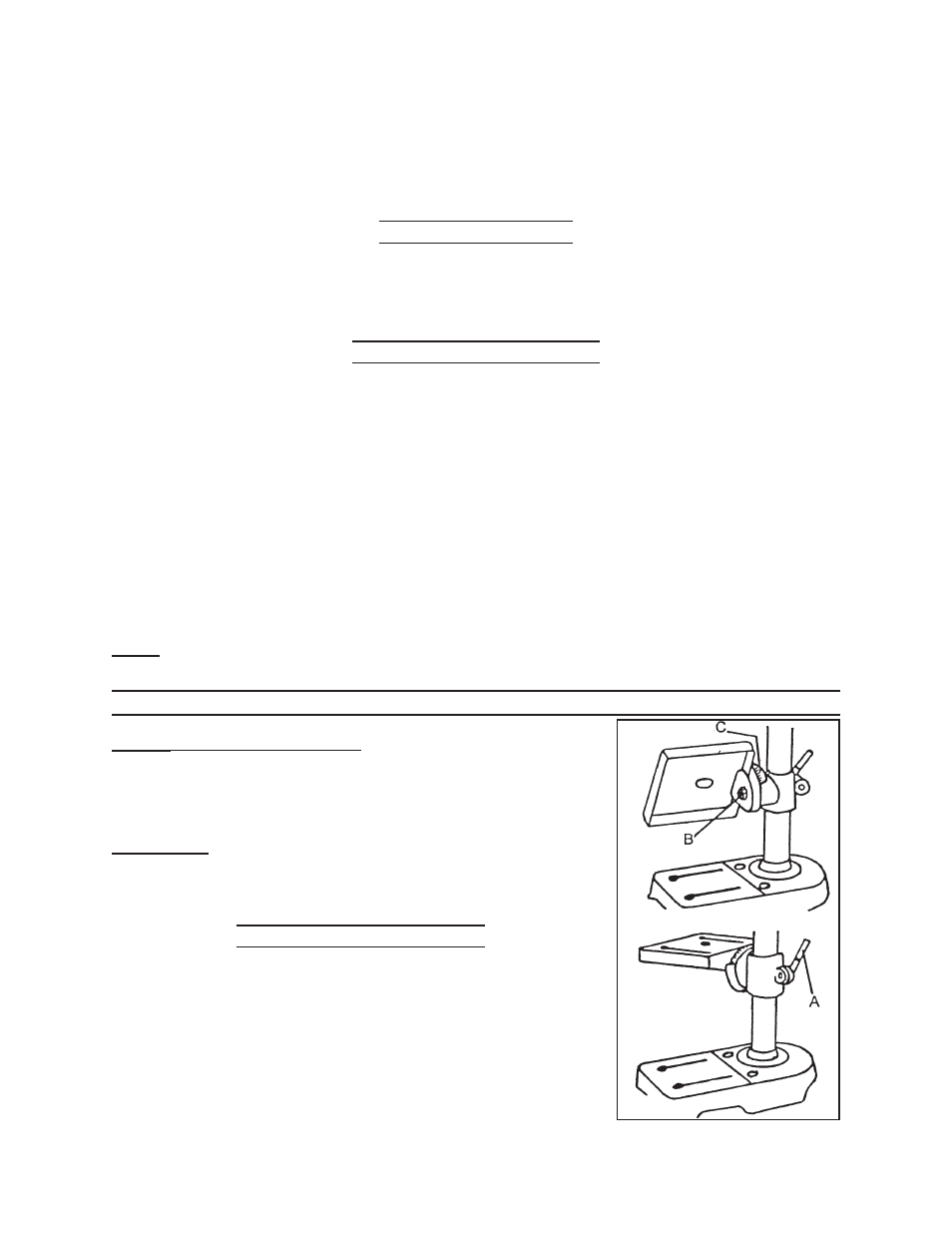

tO aDjuSt thE tabLE

The table is capable of being raised, lowered, or

swiveled about the column by:

Loosening the table support locking handle (A),

1.

adjusting as desired, and re-tightening the handle; or,

Loosening the Set Screw (B), tilting to the desired

2.

position (up to 45° in either direction), and tightening.

Figure 3

REV 01b