Harbor Freight Tools CENTRAL PNEUMATIC 93305 User Manual

Page 9

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

SKU 93305

Page 9

IMPORTANT: Before using for the first time, the spray gun must be cleaned

using a solvent based thinner. If not removed, the red oil used by the

manufacturer for testing and corrosion protection may contaminate paint.

IMPORTANT: The Spray Gun must be cleaned immediately after use.

Improper cleaning is a common reason for the Spray Gun not to work.

3.

Close the Fluid Control Knob (67) and fully open the Fluid Flow Knob (11). See

FIGURE

1 on page 6.

4.

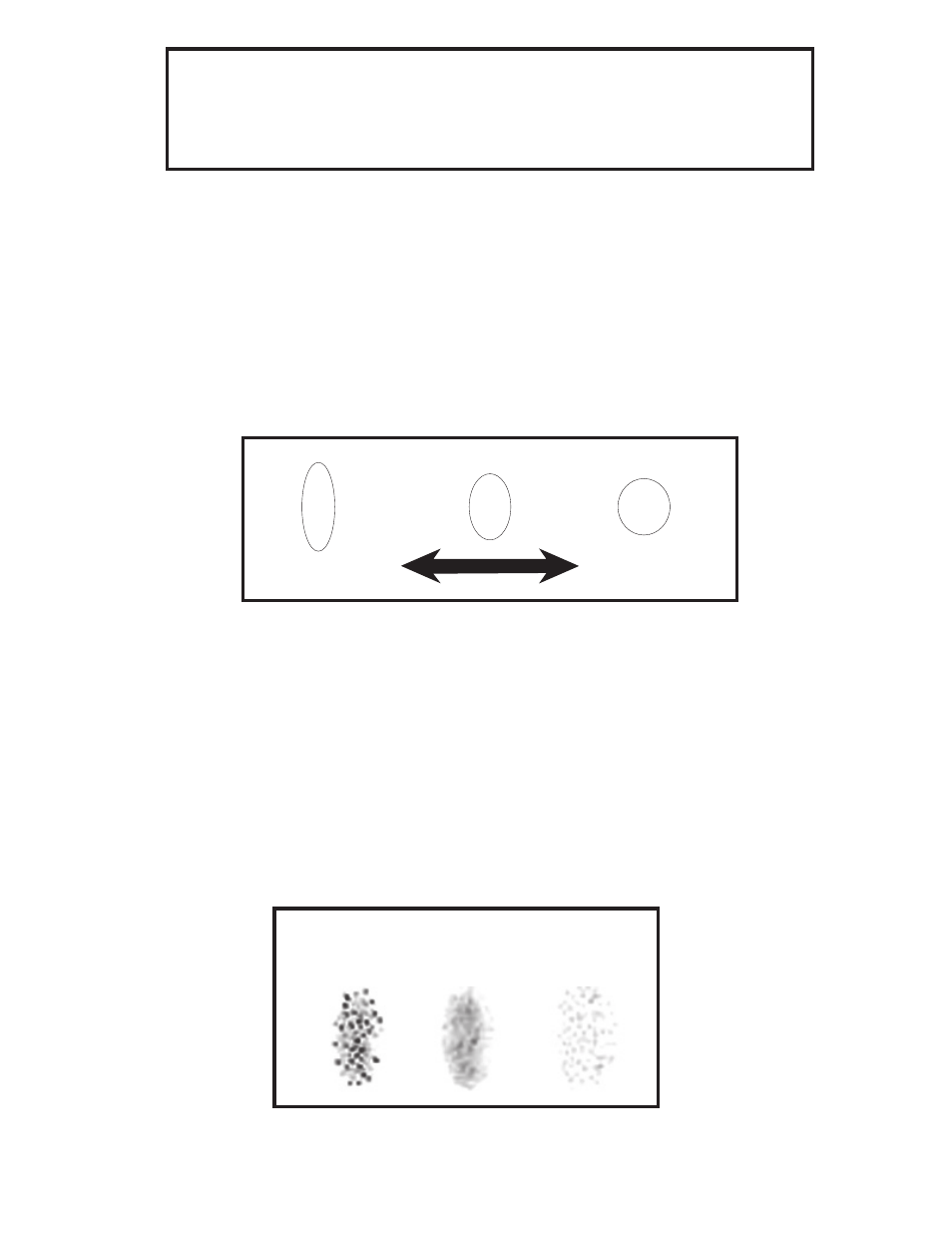

After setting up a piece of scrap material, squeeze the Trigger (78) in short bursts while

turning the Fluid Control Knob (67) counterclockwise and observe the spray patterns

until you see the pattern you want. Also, look at the pattern for consistency. Too much

air may cause the spray to come out too fine. Reduce the air pressure or allow more

material to come out by opening the Fluid Control Knob (67). If the spray appears too

thick (you see globs of paint), close down the Fluid Control Knob (67) slowly, checking

the mixture after each adjustment.

See

FIGURE 6 below.

FIGURE 6

Too Fine

(Loosen)

Too Coarse

(Tighten)

Correct

Pattern Adjustment

Warning!! Never exceed the Maximum Inlet PSI of 43 PSI.

1.

Adjust the Gauge (38) pressure to 10-30 PSI using the Air Regulator (24). If you need

to reduce the air pressure for specific areas, adjust the Air Adjustment Knob (73).

2.

To set the pattern size specific to the job, use the Pattern Control Knob (57) (see

FIG-

URE 1 on page 6). By turning it counterclockwise (all the way open), the pattern will

flatten. Turn the Pattern Control Knob (57) clockwise for a round pattern.

See

FIGURE 5 below.

Flat/Open

Round/Closed

FIGURE 5