1. positioning the torch, 2. torch movement during welding – Hobart Welding Products POWERPAK OM-478 User Manual

Page 66

OM-478 Page 62

SECTION 14 – GUIDELINES FOR TIG WELDING (GTAW)

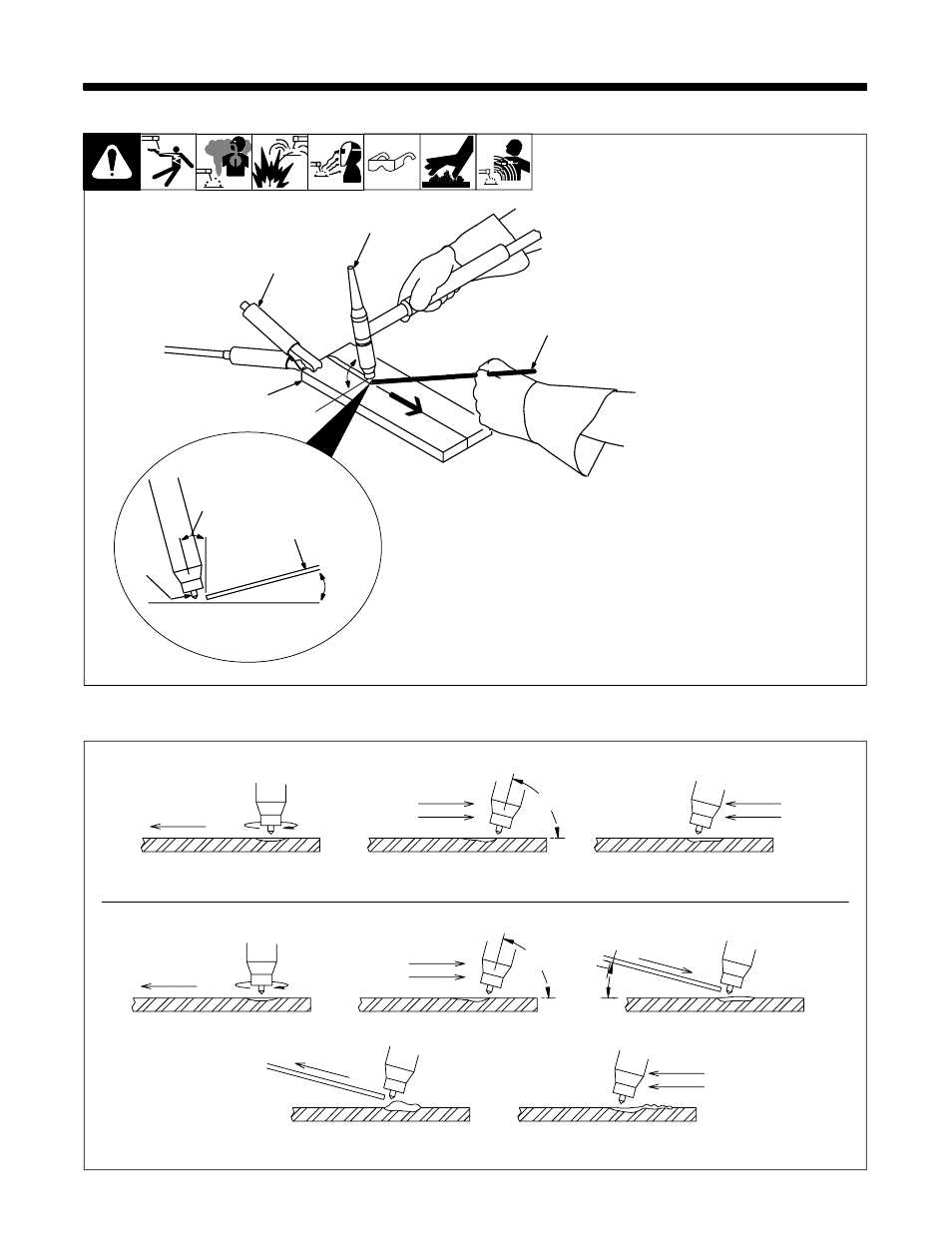

14-1. Positioning The Torch

ST-161 892

Y

Weld current can damage

electronic parts in vehicles.

Disconnect both battery

cables before welding on a

vehicle. Place work clamp as

close to the weld as possible.

1

Workpiece

Make sure workpiece is clean

before welding.

2

Work Clamp

Place as close to the weld as

possible.

3

Torch

4

Filler Rod (If Applicable)

5

Tungsten Electrode

Select and prepare tungsten

according to Sections 13-1, and

13-2 or 13-3.

Tungsten extension is the distance

the tungsten extends out gas cup of

torch.

Arc length is the distance from the

tungsten to the workpiece.

As a general guide, start with an

extension and arc length equal to

diameter of tungsten.

1

10–25

°

10–15

°

4

5

2

3

4

90

°

14-2. Torch Movement During Welding

ST-162 002-B

Tungsten Without Filler Rod

Tungsten With Filler Rod

Form pool

Tilt torch

Move torch to front

of pool. Repeat process.

75

°

75

°

Welding direction

Form pool

Tilt torch

Add filler metal

Move torch to front

of pool. Repeat process.

Remove rod

Welding direction

15

°