Inspection, maintenance, and cleaning, Troubleshooting – Harbor Freight Tools FLAT BOTTOM JACK 95967 User Manual

Page 6

Page 6

SKU 95967

For technical questions, please call 1-800-444-3353.

4.

Adding Hydraulic Oil:

• Turn the Release Valve (4) counterclockwise until Jack is completely lowered.

Remove the Filler Plug (17) from the Reservoir (16). Fill the Reservoir (16) with

oil. Use a high quality hydraulic oil.

5.

Hydraulic System Bleeding Instructions:

Caution: Never bleed the system while Flat Bottom is under a load.

a. To bleed the Flat Bottom Jack, remove the Filler Plug (17) located on the Res-

ervoir (16).

b. Open the Release Valve (4). Press and hold piston down.

c. Insert the Handle (21) in the Handle Bracket (31) and slowly pump the Handle

at least 10 times. Continue pumping until no more air bubbles appear.

d. Leave Handle in “down position” and turn clockwise to close Release Valve.

e. Raise Handle and check oil level, if necessary, top off the Reservoir with hy-

draulic oil.

f. Replace the Filler Plug.

g. Test the Flat Bottom Jack’s performance several times before attempting to lift

an object with the shop crane.

Once satisfied that the shop crane is operating properly, then the crane is ready

to lift an object. (See Figure D.)

INSPECTION, MAINTENANCE, AND CLEANING

BEFORE EACH USE, inspect the general condition of the tool. Check for loose

screws, misalignment or binding of moving parts, cracked or broken parts, damaged elec-

trical wiring, and any other condition that may affect its safe operation. If abnormal noise

or vibration occurs, have the problem corrected before further use. Do not use damaged

equipment.

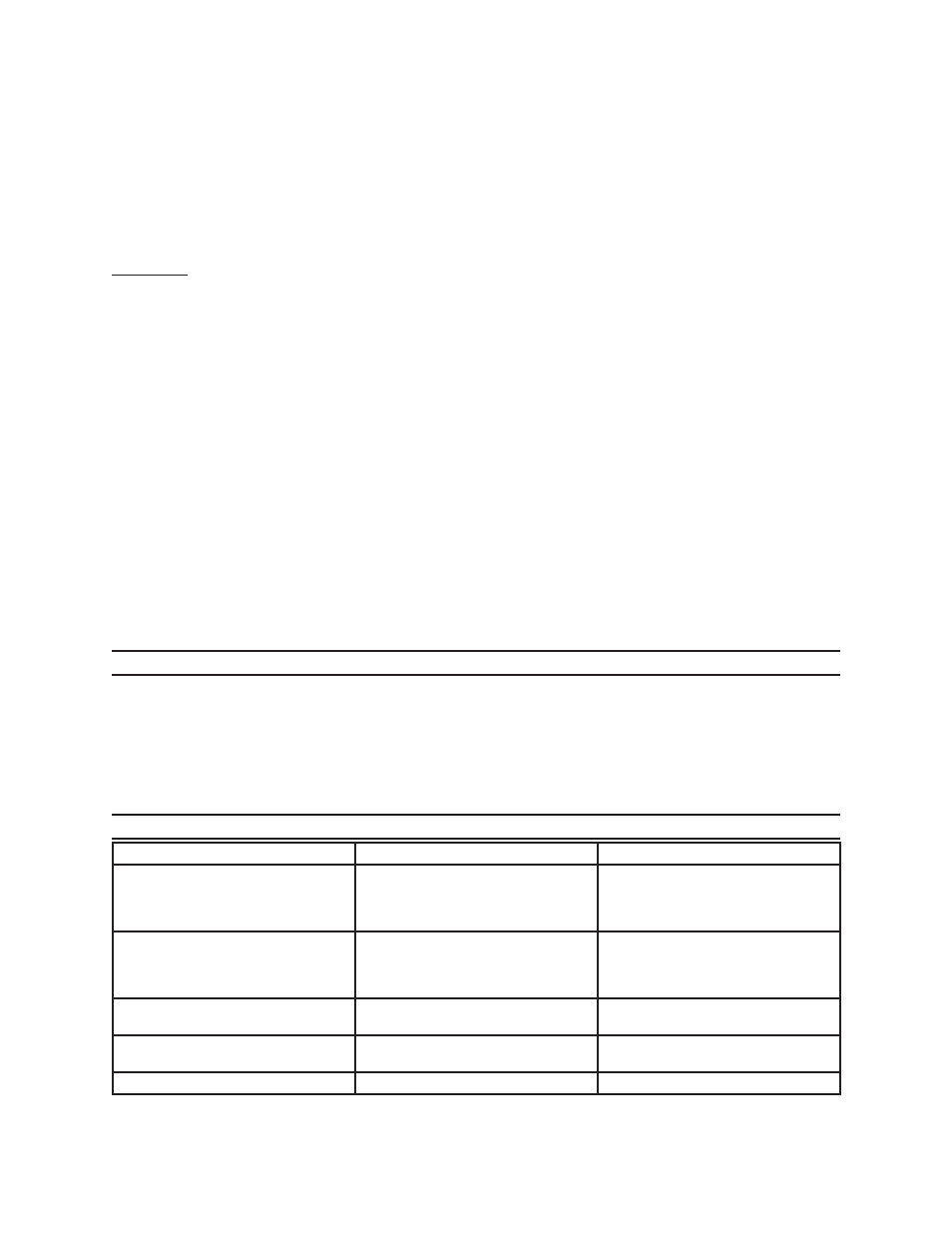

TROUBLESHOOTING

Problem

Possible Causes

Possible Solution

Jack will not lift load.

1. Release Valve not tightly closed.

2. Overload condition.

3. Air supply inadequate.

4. Air trapped in system.

1. Close Release Valve firmly.

2. Do not exceed 8 ton lifting capacity.

3. Ensure adequate air supply.

4. Purge air from system.

Jack will lift, but will not maintain

pressure.

1. Release Valve not tightly closed.

2. Overload condition.

3. Hydraulic unit malfunction or defective

seals.

1. Close Release Valve firmly.

2. Do not exceed 8 ton lifting capacity.

3. Have a qualified service technician

check the hydraulic unit.

Jack will not lower after it is raised.

1. Reservoir overfilled.

2. Linkages binding.

1. Drain oil to proper level.

2. Clean and lubricate moving parts.

Poor lift performance.

1. Hydraulic oil level low.

2. Air trapped in system.

1. Add oil to proper level.

2. Purge air from system.

Will not lift to maximum height.

Hydraulic oil level low.

Add oil to proper level.