Trouble shooting guide econo-mizer, Trouble shooting – HP 982 User Manual

Page 10

10

Trouble Shooting Guide

Econo-Mizer

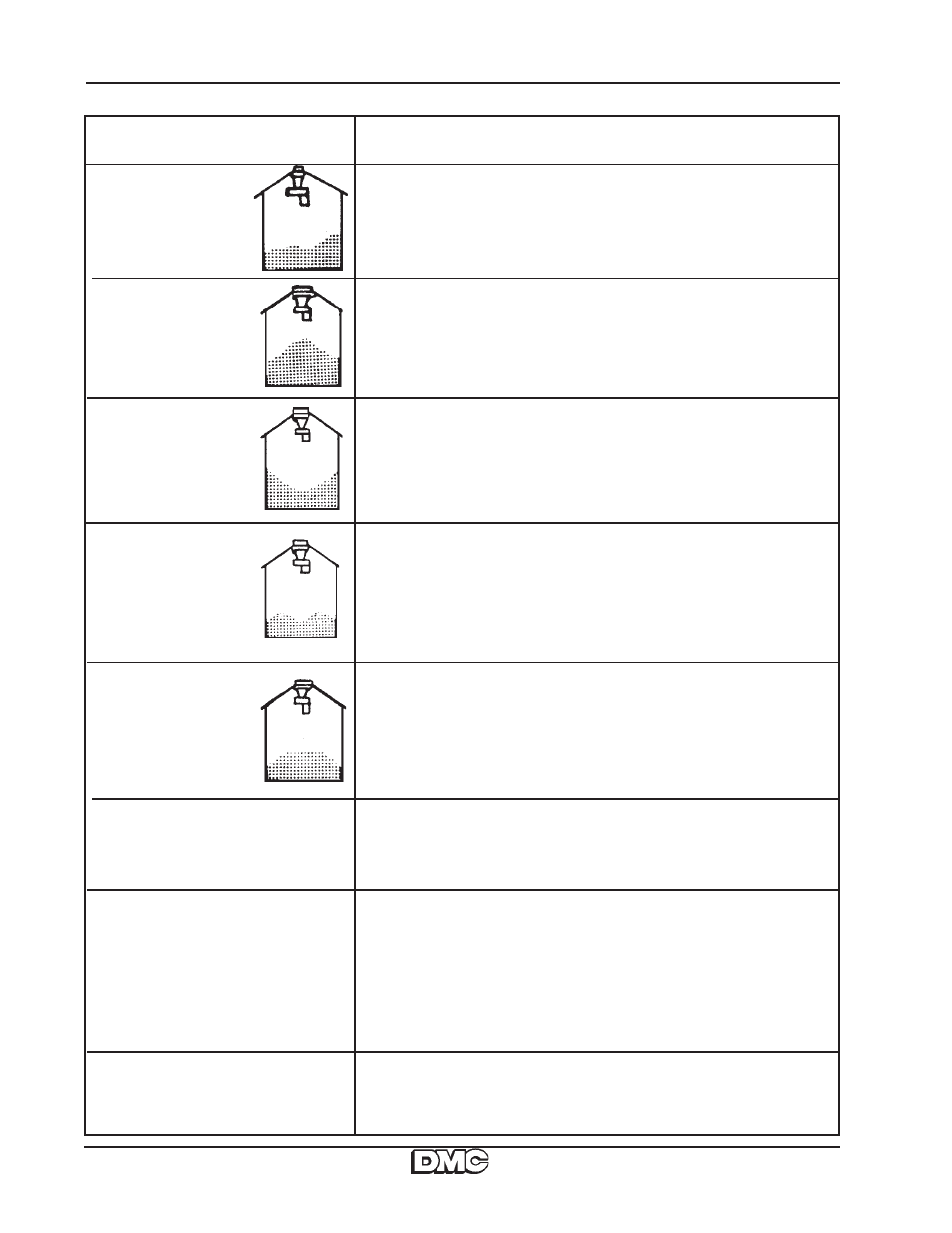

Grain is high on

one side of bin.

a. Spreader is not hung level.

b. Grain is not hitting the center of the baffle

c. The baffle is too high causing the grain to slide off one side.

d. The flow of grain is not adequate to fill the center hopper,

see instructions for cone baffle hopper.

Grain is high at the

center of bin.

a. Slide gate is open too far.

b. Check to make sure spreader is running.

c. Grain is overflowing the main hopper - raise center baffle

or slow grain flow rate.

Grain is low at the

center of bin.

a. Slide gate is not open enough.

b. Slingers on pan are set too far out.

Grain forms “donut”

a few feet from wall.

a. Slingers on pan are set too far out (grain is hitting the wall

and bouncing back).

b. Open slide gate to fill center of bin.

c. Spreader model is not adequate for bin size.

Grain not getting

all the way to wall.

a. Spreader pan is turning the wrong direction: Pan should

turn clockwise when viewed from the top.

b. Rubber drive wheel is slipping - replace if badly worn.

c. Spreader is hanging too high in the center of the bin.

d. Spreader model is not adequate for bin size.

Spreader swings

when starting.

a. Hanging chains are not installed correctly - they should

be equally spaced and positioned as in Figure 2 of

installation instructions.

Spreader does

not run.

a. Rubber drive wheel may be slipping due to excessive

moisture or broken motor mount spring.

b. Motor overload may have tripped. It will reset auto-

matically after the motor has cooled.

c. Blown fuse or circuit breaker.

d. Too much voltage drop. See Table A for proper wiring

size.

TROUBLE SHOOTING

a. Spreader pan is turning the wrong direction: Pan should

turn clockwise when viewed from the top.

Spreader pan slows

down when loaded.

PROBLEM

CORRECTION