Installation, Warning – HP HUSKY 716 User Manual

Page 2

2

308983

Installation

Pressure Relief Procedure

WARNING

PRESSURIZED EQUIPMENT HAZARD

The equipment stays pressurized until pressure is

manually relieved. To reduce the risk of serious

injury from pressurized fluid, accidental spray, or

splashing fluid, follow this procedure whenever you

D

Are instructed to relieve pressure

D

Stop pumping

D

Check, clean, or service any system equipment

D

Install or clean fluid nozzles

1.

Shut off the air to the pump.

2.

Open the dispensing valve, if used.

3.

Open the fluid drain valve to relieve all fluid

pressure, and have a container ready to catch the

drainage.

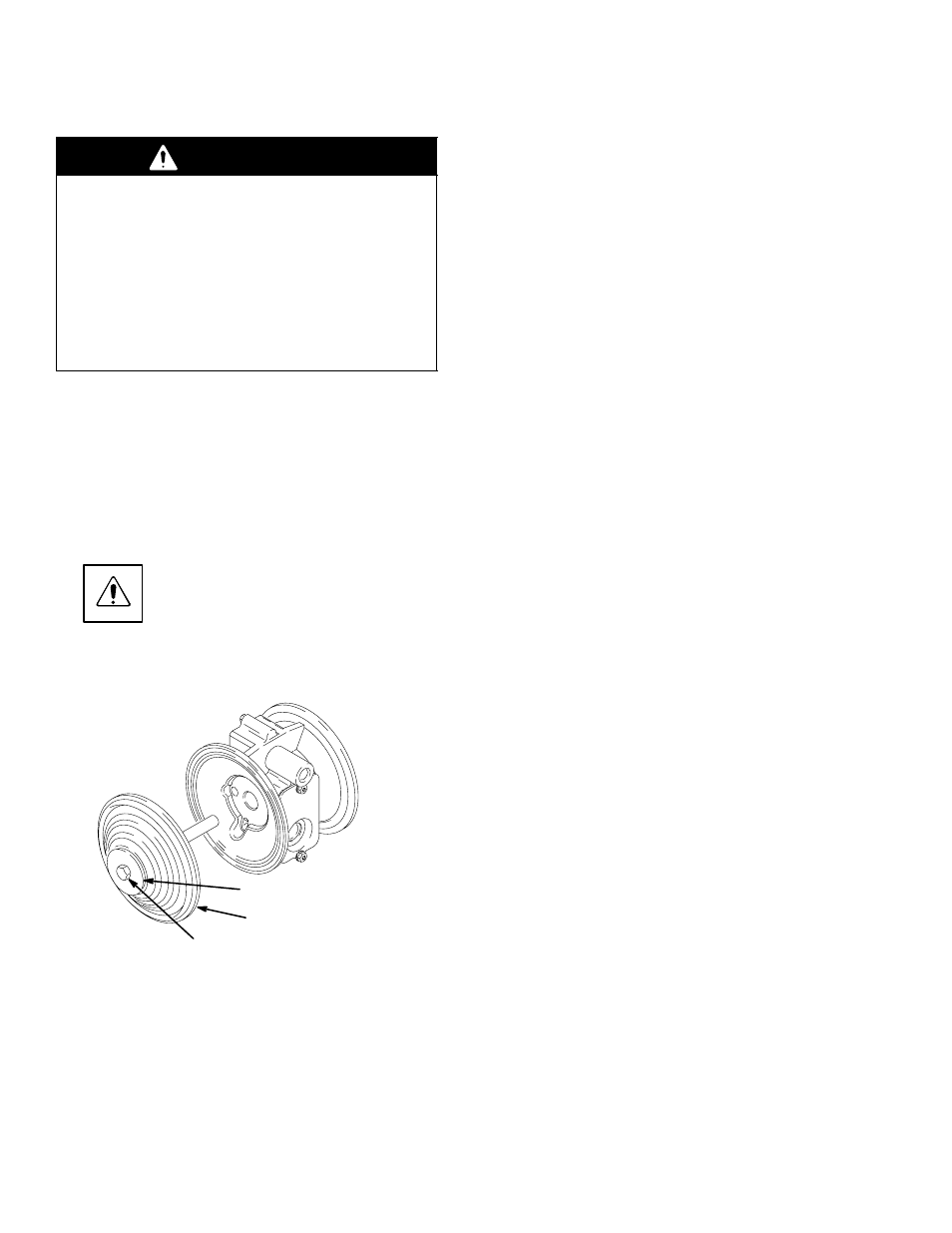

Removing the Existing Air Motor

1.

Follow the Pressure Relief

Procedure above.

2.

Remove the outlet and inlet manifolds, grounding

strip, and vee clamps. Remove the center housing

(shown below) from your Husky 715 pump.

fluid-side diaphragm plate

diaphragm shaft screw

diaphragm

9091A

3.

From the center housing that you took off of the

pump, remove the diaphragm shaft screws,

fluid-side diaphragm plates, and diaphragms. You

will re-use these. Do not re-use the diaphragm

shaft or the air-side diaphragm plates with the new

air motor.

Installing the New Air Motor

1.

Apply medium-strength (blue) Loctite

R

(9) or

equivalent to threads of diaphragm shaft screw.

Install on one end of the diaphragm shaft the

following parts (see proper order in Parts

Drawing): air-side diaphragm plate, diaphragm,

fluid-side diaphragm plate, packing o-ring (7), and

diaphragm shaft screw.

NOTE: The words “AIR SIDE” on the diaphragm

and the flat side of the air-side diaphragm plate

must face toward the diaphragm shaft.

2.

Put grease (8) on the diaphragm shaft, and

carefully (do not damage the shaft u-cups) run the

diaphragm shaft through the center housing bore.

3.

Repeat step 1 for the other end of the diaphragm

shaft, and torque the diaphragm shaft screws to 80

to 90 in-lb (9 to 10 N-m) at 100 rpm maximum.

4.

Install the muffler.

When installing vee clamps in step 6, orient center

housing so air inlet is approximately 45

_

above

horizontal and the muffler is approximately horizontal.

5.

Apply thin, even film of grease on inside of vee

clamp.

6.

Position fluid covers, install vee clamps around

fluid and air covers, install grounding strip on vee

clamps, and torque vee clamp nuts from 80 to 90

in-lb (9 to 10 N-m).

7.

Make sure all check valve parts are in place.

8.

Install manifold o-rings (6) and manifolds, and

torque manifold bolts from 80 to 90 in-lb (9 to

10 N-m).

Operating the Retrofitted Pump

See instruction manual 308981 for Operating and

Service instructions and Parts information.