2. troubleshooting – Hobart Welding Products 150 STI User Manual

Page 16

OM-951 Page 14

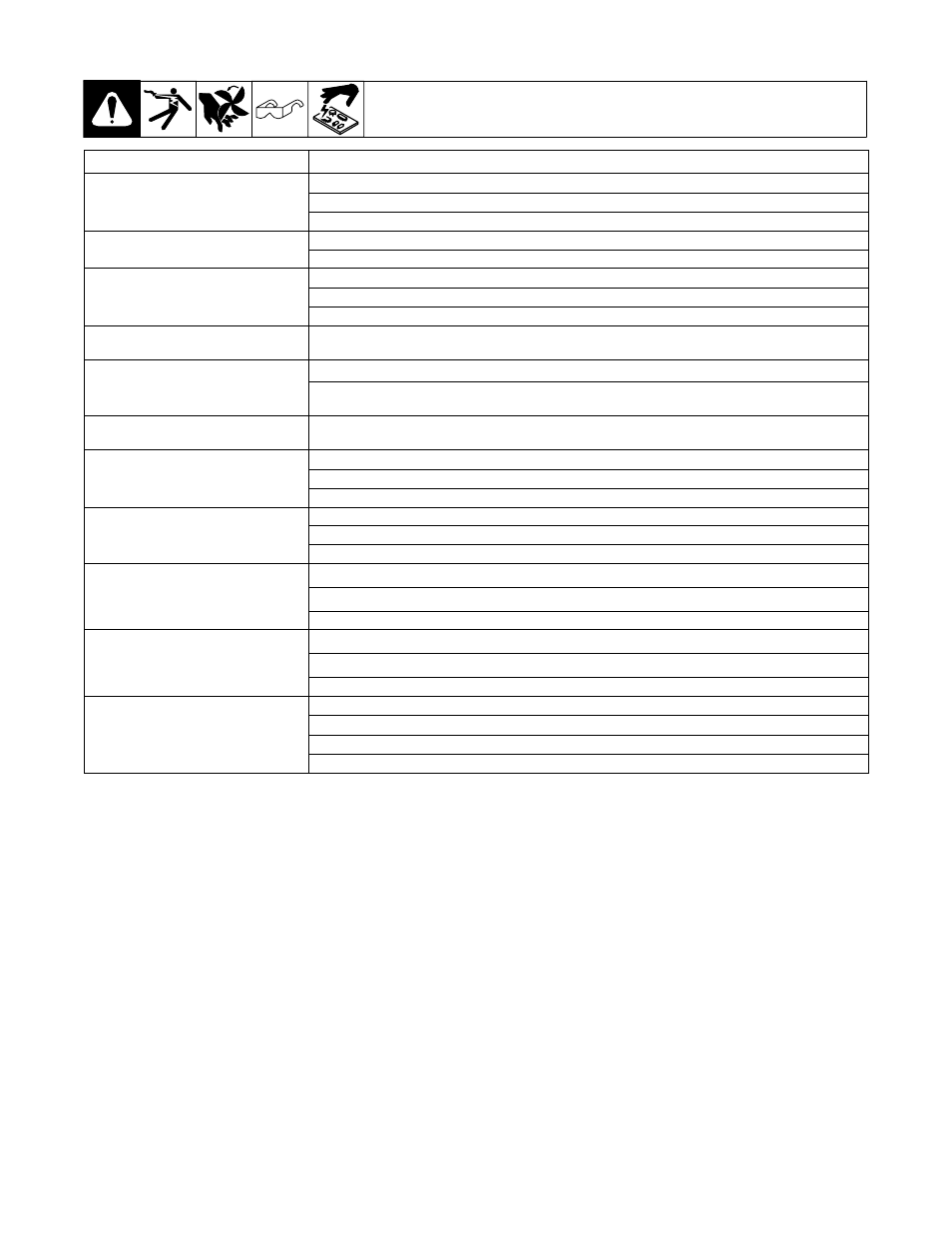

6-2. Troubleshooting

Trouble

Remedy

No weld output; unit completely inop-

ati

ad li ht Off

Place line disconnect switch in On position.

p

p

y

p

erative; ready light Off.

Check and replace line fuse(s), if necessary, or reset circuit breaker.

Be sure power cord is plugged in and that receptacle is receiving input power.

No weld output; ready light On.

Check and secure loose weld cable(s) into receptacle(s).

Check and correct poor connection of work clamp to workpiece.

No weld output; high temperature light

O

Unit overheated causing thermal shutdown. Allow unit to cool with fan On (see Section 4-2).

p

g

p

g

On.

Reduce duty cycle or amperage.

Check and correct blocked/poor airflow to unit (see Section 4-4).

No weld output; high temperature light

Flashing.

Turn Power Off and back On again. If light continues to flash, check with Factory Authorized Service

Agent.

No weld output. Blue light flashes contin-

uously yellow LED off

Line voltage to high or to low. Line voltage must be within

±

10%.

uously, yellow LED off.

Unit needs to be reset. Cycle power off and back on. If problem is not corrected, contact Factory Autho-

rized Service Agent.

No weld output. Blue LED flashes 3

times repeatedly, yellow LED off.

Remote trigger left on. Turn off remote trigger, wait 5 seconds, and restart operation.

Erratic or improper welding arc or out-

t

Use proper size and type of weld cable (see your Distributor).

p p

g

put.

Clean and tighten weld connections.

Check and reverse polarity; check and correct poor connections to workpiece.

Fan not operating.

Unit not warmed up enough to require fan cooling.

Check for and remove anything blocking fan movement.

Have Factory Authorized Service Agent check fan motor and control circuitry.

Stick welding problems: Hard starts;

poor welding characteristics; unusual

Use proper type and size of electrode.

poor welding characteristics; unusual

spattering.

Check and reverse electrode polarity; check and correct poor connections.

Make sure a remote control is not connected.

TIG welding problems: Wandering arc;

hard starts; poor welding characteris-

Use proper type and size of tungsten.

hard starts; poor welding characteris-

tics; spattering problems.

Use properly prepared tungsten.

Check and reverse electrode polarity.

TIG welding problems: Tungsten elec-

t d idi i a d t

ai i b i ht

Shield weld zone from drafts.

g p

g

trode oxidizing and not remaining bright

after welding.

Check for correct type shielding gas.

after welding.

Check and tighten gas fittings.

Check and change electrode polarity.