2. process selection, 3. lift-arce, Section 6 − maintenance and troubleshooting – Hobart Welding Products 150 STI User Manual

Page 15: 1. routine maintenance, 3. lift-arc

OM-951 Page 13

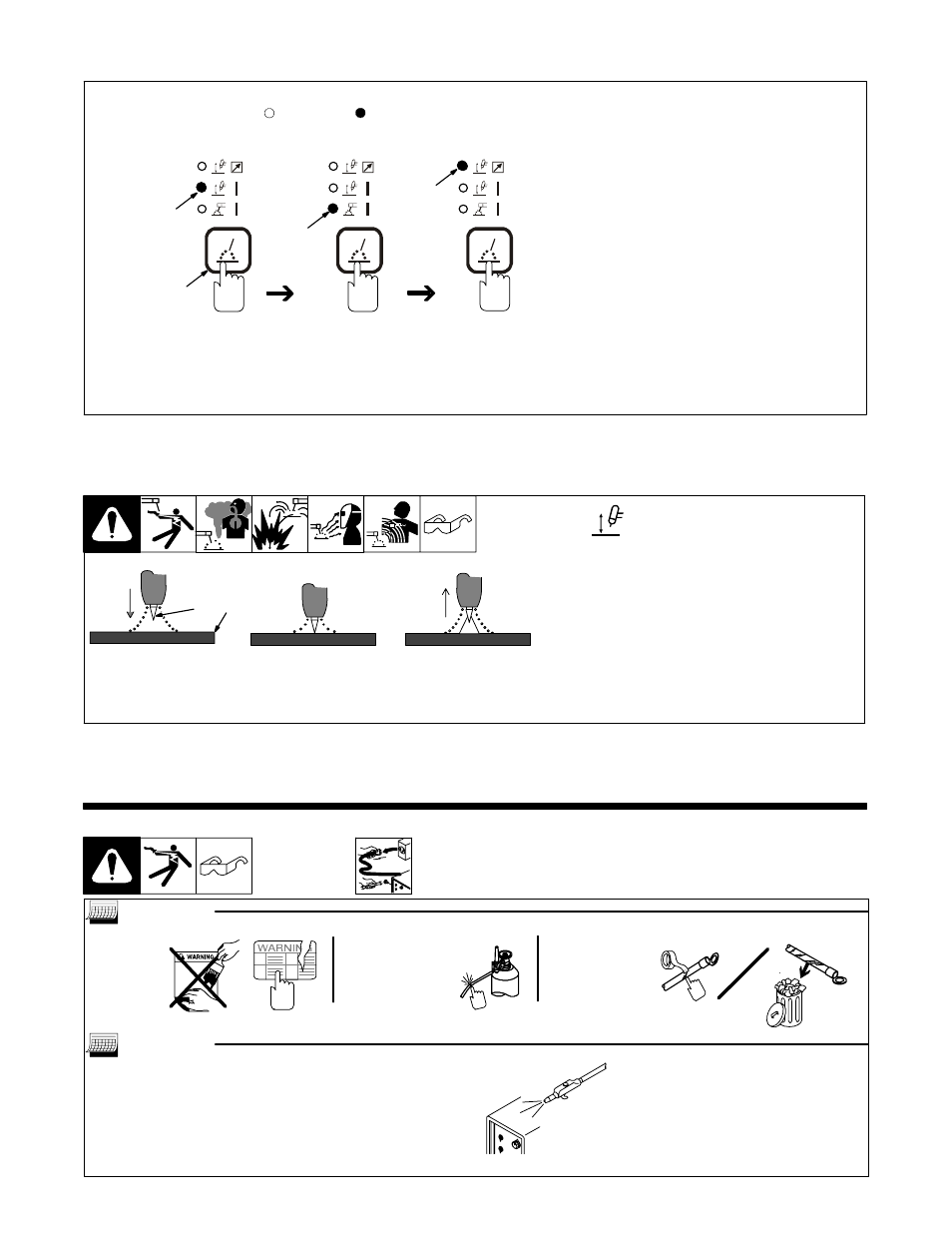

5-2. Process Selection

1

Process Selector Switch Pad

Use control to select required welding

process. Press switch pad until LED

for desired process is illuminated.

2

Lift Arct Start

When selected, a TIG arc starting

method in which the electrode must

come in contact with the workpiece to

initiate an arc is activated (see Section

Stick (SMAW)

When selected, Adaptive Hot Start

and DIG circuitry are energized.

4

Lift Arct Start (Remote)

A TIG starting method in which the

electrode must come in contact with

the work and a closure from pin 1 to pin

2 on the remote receptacle (see Sec-

tion 4-6) is required to initiate an arc.

1

Press

Press

2

3

=Light Off

=Light On

Press

4

5-3. Lift-Arc

™

Lift-Arc Start

1

TIG Electrode

2

Workpiece

Touch tungsten electrode to work-

piece, hold for 1-2 seconds, slowly

lift electrode, and an arc forms.

Open-circuit voltage may be present

before electrode touches workpiece.

1

1 − 2

Seconds

“Touch”

Do NOT Strike Like A Match!

2

SECTION 6 − MAINTENANCE AND TROUBLESHOOTING

6-1. Routine Maintenance

Y Disconnect power before maintaining.

.

Maintain more often during severe conditions.

3 Months

Replace

unreadable

labels.

Replace Damaged

Gas Hoses

Repair Or Replace

Cracked Cables

And Cords

6 Months

Blow out inside. Direct airflow through front and back louvers.

Y Do not remove case when blowing out inside of unit .