Mantenimiento, Notice, Preparation – Husky HDS420 User Manual

Page 22: Set up (continued)

22 Sp

Pistola Pulverizadora Multiuso

Mantenimiento

(Continuación)

5. Sáquele las tuercas que sostienen los

empaques y reemplácelos SOLO si no

puede eliminar la fuga de material

después de apretar las tuercas. No

apriete demasiado estas tuercas ya

que podría restringir el movimiento

de la aguja.

6. Ensamble las piezas en orden

contrario a lo anterior y use aceite sin

silicón en las piezas movibles.

Aplíquele Vaselina o grasa liviana a

las conexiones con roscas y a las de

las mangueras.

a cardboard target. Be sure the spray

material is clean and free from lumps.

3. Fill the canister about 3/4 full with

material and start the air

compressor. Be sure the hose(s) is

long enough to allow a full

movement of the gun across the

surface to be painted.

4. Be sure that the air pressure

regulator is set for the proper

operation of the gun. Refer to the

specifications section. Air pressure

should be checked at the spray gun

inlet with the trigger pulled.

5. Set up a piece of cardboard or other

scrap material to use as a target and

adjust for best spray pattern.

MATERIAL & PATTERN

ADJUSTMENTS

Always test spray

gun on scrap

material to avoid damage to workpiece.

The fluid control knob will control

trigger travel and the amount of

material flowing through the gun.

(Turn the knob clockwise to reduce

flow, counterclockwise to increase the

flow.) This adjustment depends, in

part, on the amount of air flowing

through the gun. Air flow can be

adjusted only at the compressor’s

pressure regulator. Spray test patterns

on scrap cardboard with gun 8” away

from surface. Trigger short, one second

bursts and make adjustments with this

knob until the pattern is the desired

oval shape and the material is evenly

distributed on the surface with no

heavy or thin spots. The pattern should

feather out at the edges (See Figure 5).

NOTE: If there is sagging, too much

material is being applied. If there is an

“orange peel” effect, the material is

too thick.

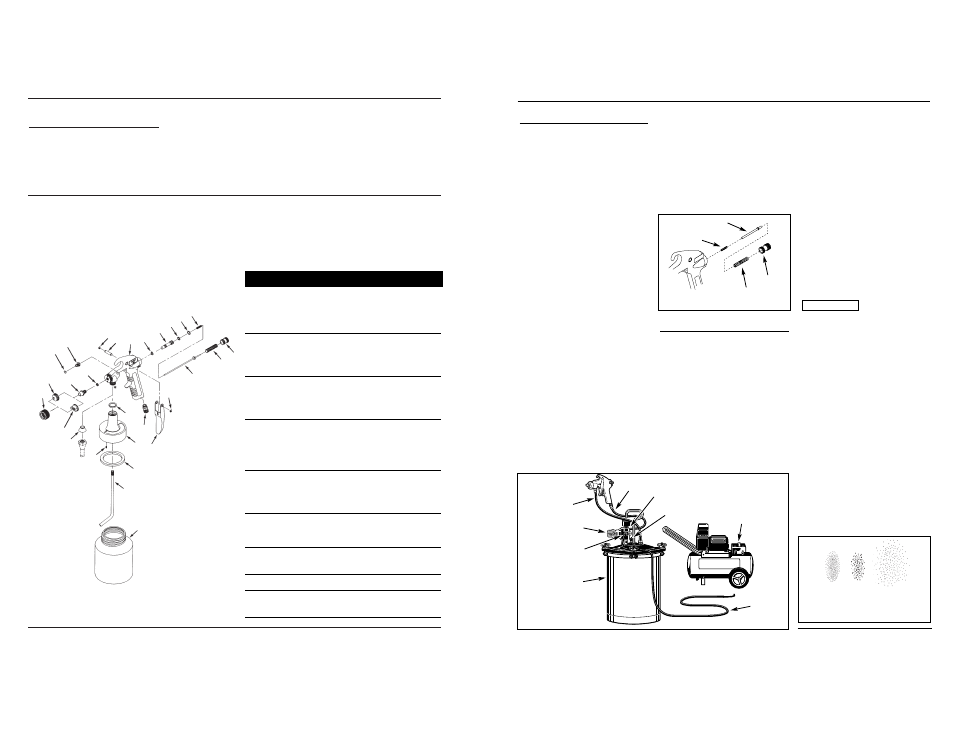

NOTICE

NON-BLEEDER TO BLEEDER

CONVERSION

IMPORTANT: Spray guns are shipped

for non-bleeder operation.

(See Figure 4)

1. Remove fluid control knob, large

spring and fluid needle.

2. Remove and retain small spring or

place inside large spring to store.

3. Reassemble unit by reversing step 1.

Preparation

MATERIAL PREPARATION

1. Before using desired material in the

spray gun, spray a compatible

thinner or solvent through the gun

to remove any contaminants and

residue.

2. Thoroughly mix the material in

accordance with the manufacturer’s

instructions. If necessary, thin per

paint manufacturer’s instructions.

Strain material through a paint

strainer. Test the consistency of the

material by making a few strokes on

3

Set Up (Continued)

USING A PRESSURIZED PAINT TANK

This model is readily adaptable for use

with a pressurized paint tank. This

allows continuous spraying of large

quantities of paint without stopping. It

also allows the gun to be used while

being held in ANY position without

spilling paint.

The proper connections to make when

using a pressurized paint tank are as

illustrated in Figure 3. Refer to the

instructions supplied with the paint

tank for connections and usage. DO

NOT USE A PAINT TANK WITHOUT

READING THOSE INSTRUCTIONS.

Prepare the spray gun for use with the

paint tank as follows:

1. Remove canister.

2. Unscrew the material tube.

3. Unscrew canister top and O-ring.

4. Remove setscrew from hole in

canister cover.

5. Remove air cap to expose the fluid

tip.

6. Locate the small tapped hole below

the fluid tip and assemble the

setscrew into this hole.

7. Fasten the material hose from the

paint tank to the gun body in place

of the canister.

NOTE: Be sure to use the adapter

when attaching the material hose (See

Figure 10, item 26 for fluid hose

adapter location).

Figure 3 - Paint Tank

Connections

Paint Tank Regulator

Safety Valve

Air Hose

Paint Tank

Material Hose

Air Hose

High - Out To Spray Gun

High - In from

compressor

Air Source

Regulator

Fluid

Control

Knob

Fluid Needle

Large Spring

Small Spring

Figure 4

Correct

Paint Too

Thick

Paint

Too Thin

Figure 5 - Pattern Consistency

(Atomization)

PARA ALMACENAR

1. Cuando no vaya a usar la pistola

pulverizadora, gire la perilla de

control de fluído en sentido

contrario a las agujas del reloj para

reducir la tensión del resorte sobre

la aguja.

2. La pistola pulverizadora DEBE estar

bien limpia y ligeramente lubricada.

Para ordenar repuestos, sírvase llamar al concesionario

más cercan a su domicilio

Puede escribirnos a:

The Campbell Group

Attn: Parts Department

100 Production Drive

Harrison, OH 45030 U.S.A.

1

Ensamblaje del cuerpo

de la pistola

No disponible 1

2

Anillo retenedor

■

2

3

Pasador del gatillo

■

1

4

Ensamblaje de la aguja de flujo

●

1

5

Anillo de la tapa de aire

▲

1

6

Tapa de aire (mezcla externa)

▲

1

7

Tapa de aire (mezcla interna)

▲

1

8

Boquilla

●

1

9

Anillo en O de 8,7mm x 5,6mm

■

2

10

Resorte

●

1

11

Perilla para el control del material

●

1

12

Pistón de la válvula

●

1

13

Anillo en O de 10mm x 6,4mm

■

1

14

Anillo en O de 11mm x 8mm

■

1

15

Resorte

●

1

16

Anillo en O de 17mm x 22mm

■

1

17

Empaque

(●) (■)

1

juego

18

Tuerca para sostener el empaque

●

1

19

Ensamblaje

DH404200AV

1

20

Tornillo de cabeza tubular

de 5-40 x 3,2mm

●

1

21 ■ Empaque para el envase

(paquete de 3)

DH420400AV

1

22

Tubo de material

DH065700AV

1

23

Conexión de 6,4mm NPS (M)

para la manguera

HF001800AV

1

24

Gatillo

DH011800AV

1

25

Envase

DH054001AV

1

26

Adaptador para la

manguera de flujo

DH006900AV

1

(◆)

Llave tipo Allen de 1,6mm

ST010900AV

1

JUEGOS DE REPUESTOS DISPONIBLES

PARA LA REPARACIÓN Y MANTENIMIENTO

■

Empaques

DH420100AV

●

Control de flujo

DH420200AV

▲

Control de patrón

DH420300AV

(◆)

No se muestra

No. de

Número del

Ref.

Descripción

Repuesto

Ctd

* 3/8 NPS (M)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

9

Sirvase darnos la siguiente información:

- Número del modelo

- Número de Serie o código con fecha (de haberlo)

- Descripción y número del repuesto según la lista de repuestos

Figura 10