Trouble shooting – HP 936 User Manual

Page 9

9

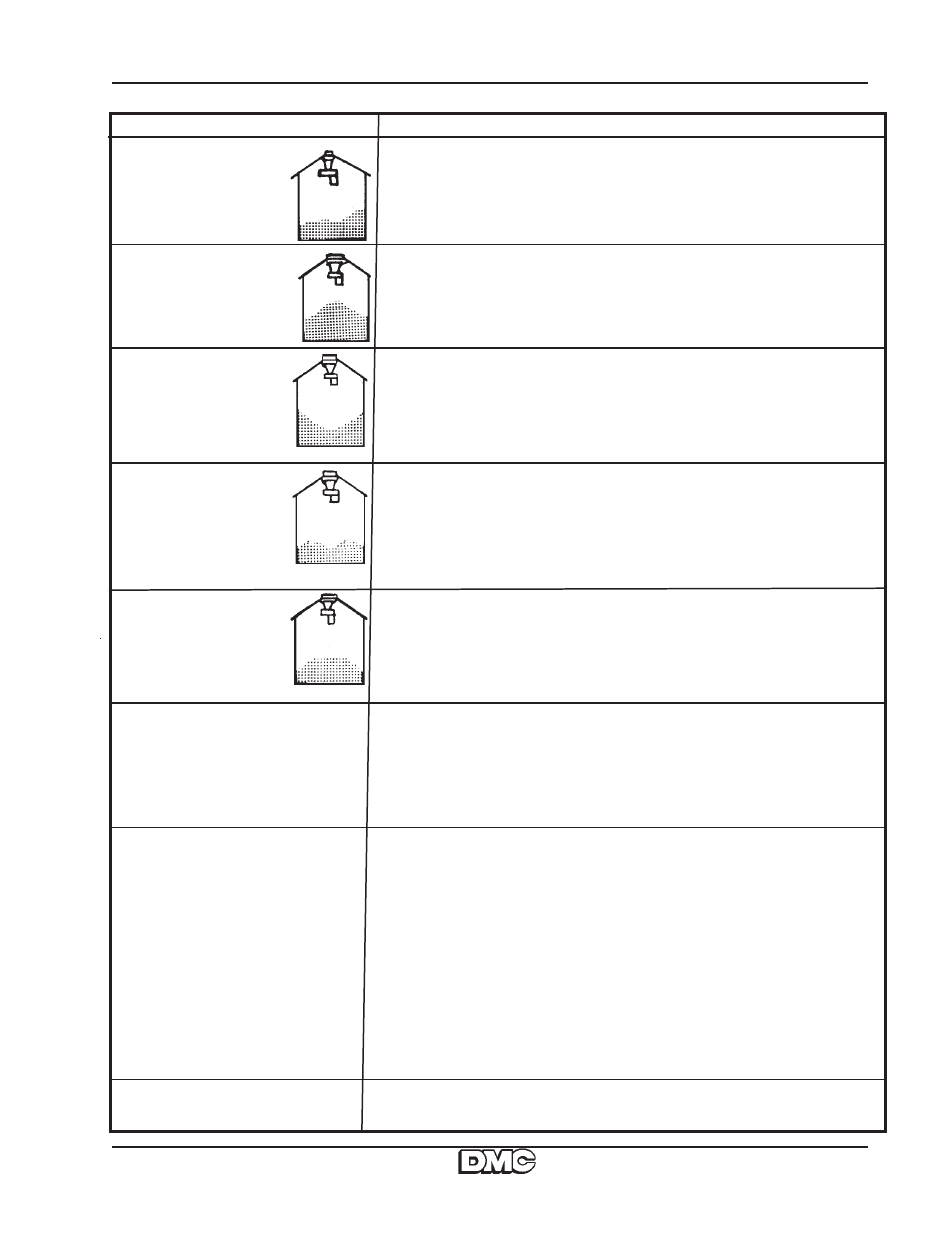

Bin Level

Spreader does not run.

(a) Mercury switch plate may be frozen shut or plugged with foreign material.

(b) Rubber drive wheel may be slipping because of excessive moisture or

broken mounting plate spring.

(c) Motor overload may have tripped. It will reset automatically after the motor

has cooled.

(d) Blown fuse or broken wire.

(e) Faulty mercury switch.

(f) Mercury switch plate bent out of shape.

(g) Grain extremely high moisture may not flow enough to operate the mercury

switch plate. Bending section of the plate holding the mercury switch up to

make it more sensitive may help.

(h) The motor will not start and will “chatter” if the voltage is too high.

(i) The motor will not start and will “hum” if the voltage is too low. See Table A

on Page 8 for the proper length and size of wiring to prevent excessive

voltage drop.

Motor slows down when loaded.

(a) Motor wired for the wrong direction. Pan should turn clockwise when

viewed from the top.

(a) The Model 918 Bin Level will only spread over an entire bin width of up

to 30’ and the Model 936 up to 36’. If the bin is bigger, lower sides will

result because grain will not throw out far enough.

(b) Adjust outside ring up. See Figure 3.

(c) Bin Level hanging too high under bin roof.

(d) Rubber drive wheel badly worn.

Grain not getting all

the way to the wall.

Grain forms “doughnut”

a few feet from bin wall.

Caused by grain bouncing off bin wall excessively.

(a) Adjust outside ring. See Figure 3.

(b) Hook Spreader higher in the roof cone to increase grain bouncing off

underside of roof and then being deflected straight downward.

(c) Open slide gate more to help fill center.

(d) Spreader model not correct for bin size.

Grain is low at the

center of bin.

(a) Slide Gate not open far enough.

(b) Spreader not stopping enough to let grain out through slide gate.

See Figures 2 and 4.

(c) Outside ring set too high. See Figure 3.

Grain is high at the

center of bin.

(a) Slide Gate open too far.

(b) Spreader stopping too long, letting too much grain through slide gate.

See Figure 4.

(c) Outside ring set too low. See Figure 3.

Spreader swings exces-

sively

This condition is caused by improper hooking up of the suspension chains.

There should be the same number of links from spreader to hook with all six

strands of chain. This will also usually ensure level hanging of the Spreader.

Equal spacing of hanger brackets is important.

The hanger brackets should be on the outer fill-hole ring.

TROUBLE SHOOTING

Grain is high on

one side of bin.

(a) Spreader is not hung level.

(b) Spreader not stopping & starting properly during filling. See Figure 2.

(c) Spreader running continuously.

PROBLEM

CORRECTION