Safety opera tion maintenance setup – Harbor Freight Tools 13" FLOOR DRILL PRESS 38144 User Manual

Page 10

Page 10

For technical questions, please call 1-800-444-3353.

Item 38144

Changing Drill Speed

Before changing the speeds, make sure the

machine is switched OFF and UNPLUGGED.

1. Open the pulley cover.

2. Slacken off the Belt Tension Lock Knobs (18A)

on both sides of the head and turn the

Belt Tension Lever (19A) clockwise, to bring the

Motor Pulley (11A) closer to the Spindle Pulley (3)

in order to remove all tension from the drive belts.

3. Consult the chart inside the pulley cover and position

the belts on the pulley’s according to the spindle

which corresponds to the spindle/drill speed required.

4. When the belts have been correctly

positioned, tighten them by turning the

Belt Tension Lock Knobs (18A) until the belt

deflects by approximately 1/2″ at its center when

using reasonable thumb pressure. Lock this

position in with the two Locking Knobs (18A).

Note: If the belt is too long to

be properly tensioned, it must be replaced.

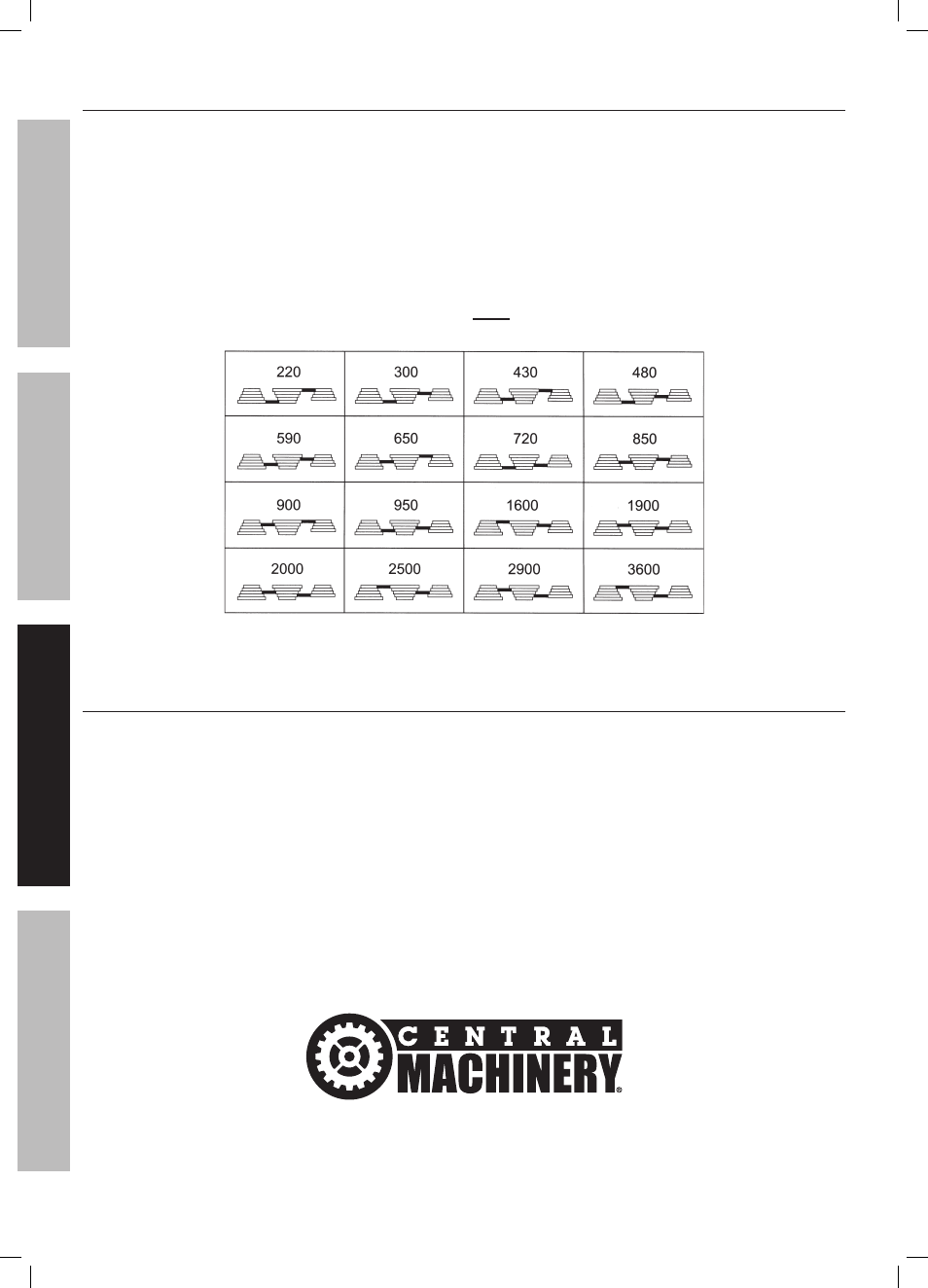

Figure C: Drill Speed Table

The table above shows the belt arrangements for given drill speeds (A full

chart is also located on the inside of the pulley cover).

Bit Installation

Insert the drill into the jaws of the chuck approximately 1″, ensuring that the jaws do not touch the flutes of the drill.

Before tightening the chuck, ensure that the drill is centered within the jaws.

SAFETY

OPERA

TION

MAINTENANCE

SETUP