3. torch and work cable connections – Hobart Welding Products 250A User Manual

Page 21

OM-928 Page 17

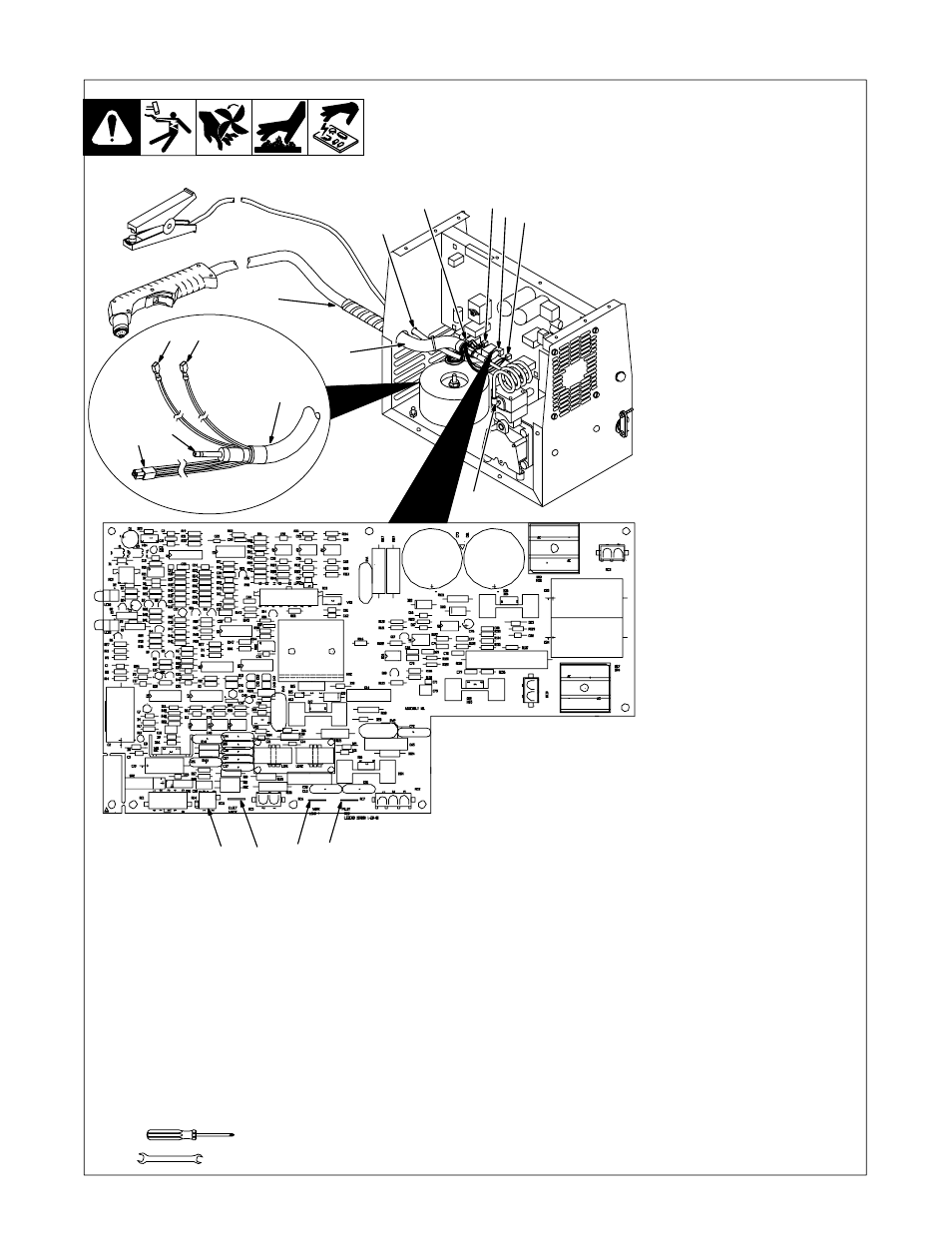

6-3. Torch And Work Cable Connections

If torch or work cable needs to be

removed or replaced, proceed as

follows:

Turn power Off, and disconnect

input power plug from receptacle.

Remove wrapper from unit.

Torch Connections

Remove existing torch cable from

unit.

1

Strain Relief

2

Torch Cable

Insert cable through strain relief.

Slide strain relief nut onto torch

cable, but do not tighten.

3

Air Line Connector

Install air line connector onto

compressor fitting.

4

Plug PLG4/Receptacle RC4

Connect PLG4 to receptacle RC4

on circuit board PC1.

5

Female And Male Friction

Terminal RC11/ELECT

WHITE

Connect female friction terminal on

end of white leads to RC11/ELECT

WHITE.

6

Female And Male Friction

Terminal RC7/PILOT RED

Connect female friction terminal on

end red leads to RC7/PILOT RED.

Tighten strain relief nut.

Tighten strain relief around cable.

Work Cable Connections

Remove existing work cable from

unit.

7

Strain Relief

.

Be sure to allow some work

cable slack inside the unit.

Insert work clamp lead through

strain relief, and install strain relief

into front panel.

8

Work Lead Male Friction

Terminal

Connect work clamp lead to male

friction terminal labeled WORK

LEAD on circuit board PC1. Route

lead along torch lead bundle.

Tools Needed:

5/8 in

1

3

7

8

4

6

2

4

5

5

8

6

Ref. 803 936-A / Ref. 801 300-B / 199 088

3

2

4

5

6