6. adjusting engine speed – Hobart Welding Products ARCSTAR 280 NT User Manual

Page 30

OM-4402 Page 26

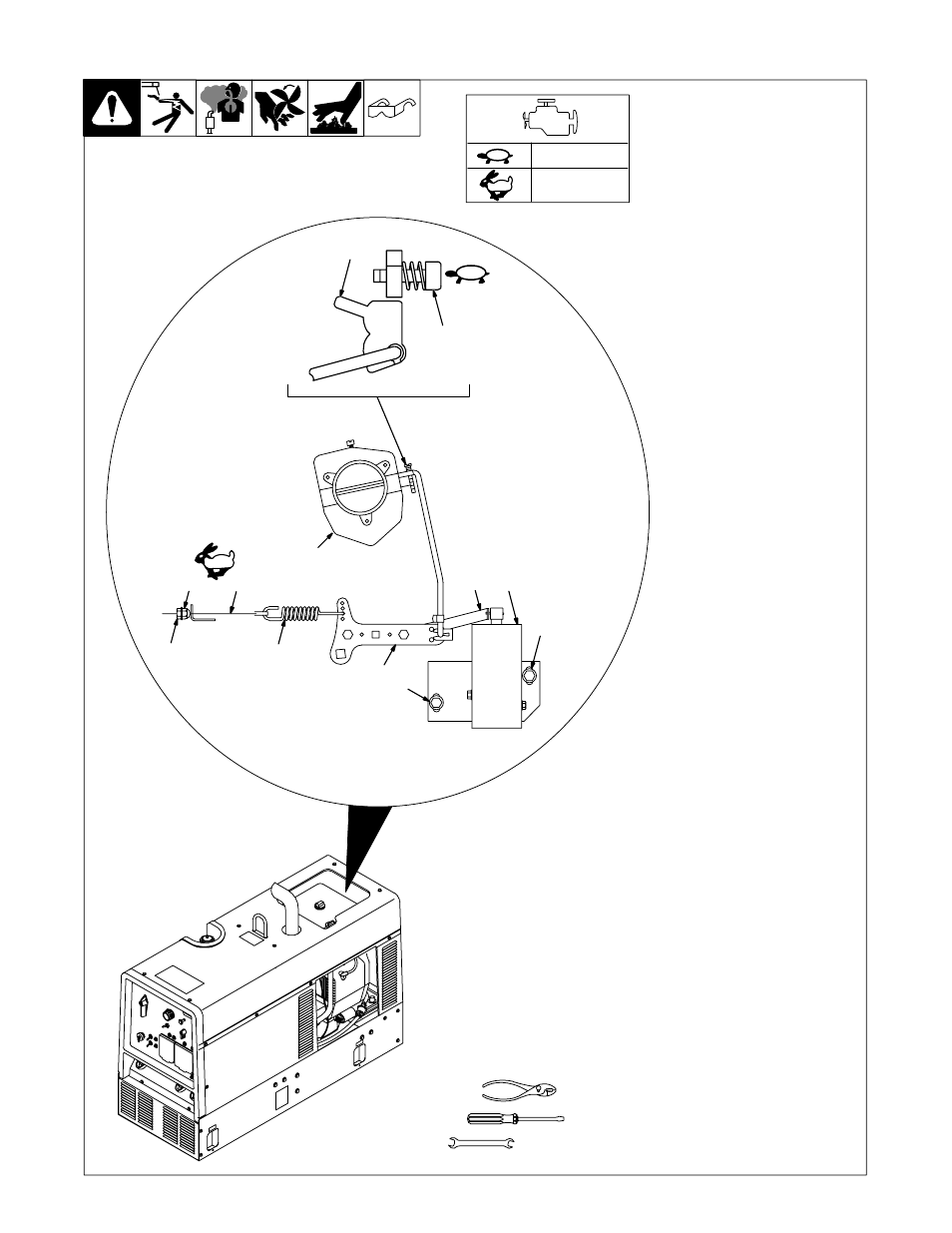

7-6.

Adjusting Engine Speed

Ref. 801 942-C / 800 397-A

After tuning engine, check engine

speeds with a tachometer (see

table). If necessary, adjust speeds

as follows:

Start engine and run until warm.

Turn A/V control to max.

Idle Speed Adjustment

1

Throttle Solenoid

2

Mounting Screw

Loosen two mounting screws.

3

Governor Arm

4

Carburetor

5

Idle Speed Screw

Pull governor arm away from

carburetor and hold while making

the following adjustment:

Turn idle speed screw until engine

runs at idle speed (see table).

Release governor arm. Place

Engine Control switch in Run/Idle

position.

6

Carburetor Stop

With solenoid energized, slide sole-

noid until idle speed screw just

touches carburetor stop. Tighten

solenoid mounting screws.

7

Governor Arm Extension

Check for smooth operation, and

readjust solenoid position if

necessary.

Weld/Power Speed Adjustment

Place Engine Control switch in Run

position.

8

Weld/Power Speed Rod

9

Locking Nut

Loosen nut.

10 Adjustment Nut

Turn adjustment nut until engine

runs at weld/power speed. Tighten

locking nut.

Y

Stop engine.

11 Sensitivity Spring

See engine manual for governor

sensitivity adjustment.

2200

±

100 rpm

3700

±

50 rpm

1/4, 3/8 in

Tools Needed:

Left Side

6

10

8

7

1

9

11

3

2

2

4

Top View

5