Heatcraft Refrigeration Products Condensing Units H-IM-CU User Manual

Page 9

9

Liquid Lines

Liquid lines should be sized for a minimum pressure drop to prevent

“flashing”. Flashing in the liquid lines would create additional pressure drop

and poor expansion valve operation. If a system requires long liquid lines

from the receiver to the evaporator or if the liquid has to rise vertically

upward any distance, the losses should be calculated to determine whether

or not a heat exchanger is required. The use of a suction to liquid heat

exchanger may be used to subcool the liquid to prevent flashing. This

method of subcooling will normally provide no more than 20

˚

F subcooling

on high pressure systems. The amount of subcooling will depend on the

design and size of the heat exchanger and on the operating suction and

discharge pressures. An additional benefit from the use of the suction to

liquid type heat exchanger is that it can help raise the superheat in the

suction line to prevent liquid return to the compressor via the suction line.

Generally, heat exchangers are not recommended on R-22 low temperature

systems. However, they have proved necessary on short, well insulated

suction line runs to provide superheat at the compressor.

Hot Gas Defrost Systems

Hot Gas Defrost systems can be described as reverse cycle, re-evap., or

alternating evaporator. Please see manual H-IM-HGD for Mohave™ systems.

Refrigerant Piping

Install all refrigerant components in accordance with applicable local and

national codes and in accordance with good practice for proper system

operation. The thermostatic expansion valve must be the externally

equalized type. It can be mounted inside the unit end compartment. Mount

the expansion valve bulb on a horizontal run of suction line as close as

possible to the suction header. Use the clamps provided with the valve to

fasten the bulb securely so there is a tight line-to-line contact between the

bulb and the suction line. Suction and hot gas connections are made on the

outside of the unit.

Suction lines should be sloped towards the compressor at the rate of one

(1) inch per ten (10) feet for good oil return. Vertical risers of more than four

(4) feet should be trapped at the bottom with a P-trap. If a P-trap is used, the

expansion valve bulb should be installed between the unit and the trap.

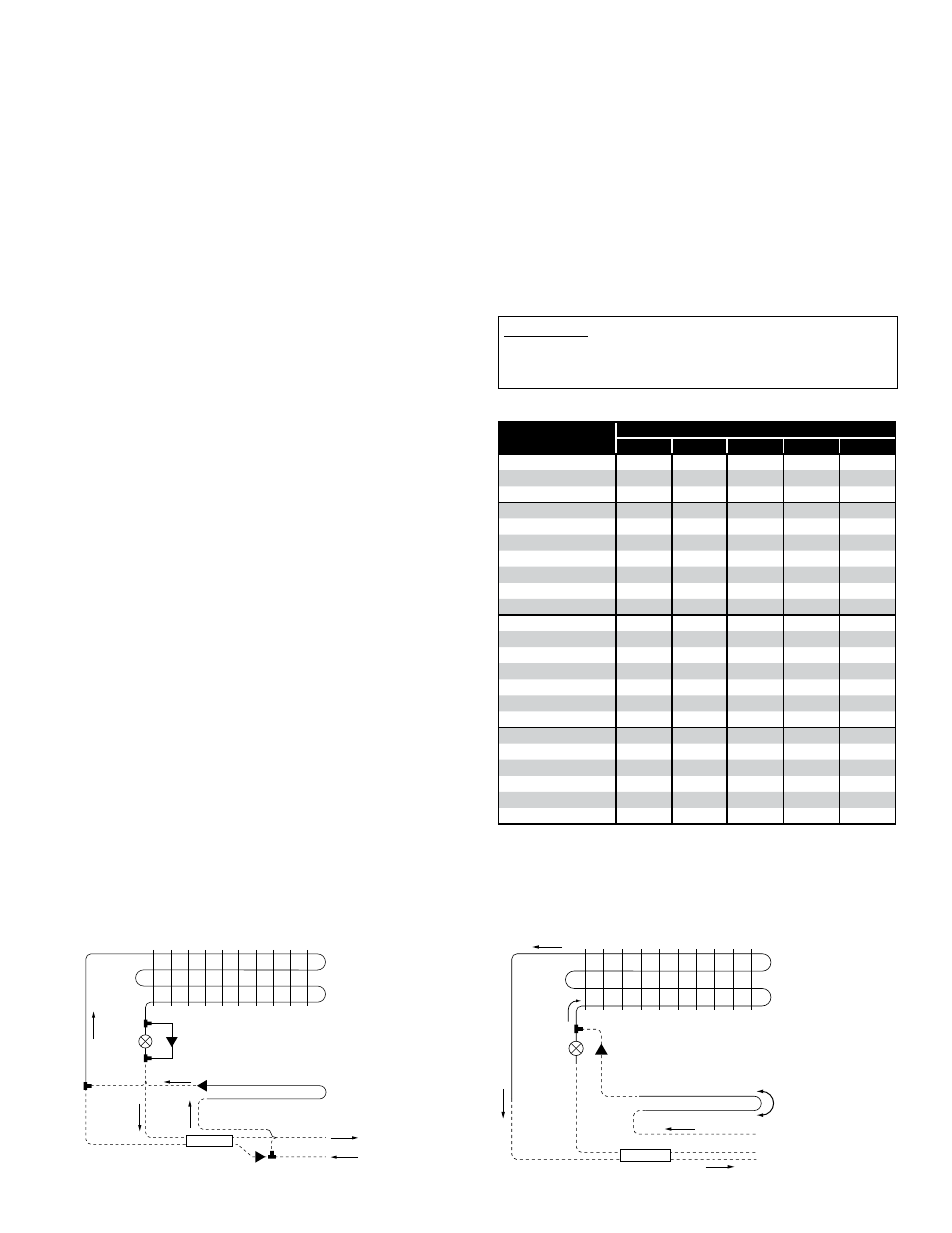

Reverse Cycle System

The hot gas unit coolers can be used in reverse cycle hot gas defrost systems

using multiple evaporators connected to one condensing unit. Generally, not

more than one-third of the system defrosts at one time. During the reverse

cycle defrost, the reversing valve, located in the compressor discharge line,

diverts hot gas through the suction line to the evaporator.

See the piping view in the Reverse Cycle Defrost Piping diagram. The suction

line check valve directs the hot gas through the drain pan loop which

prevents condensate in the pan from freezing. The hot gas exits the loop at

the pan loop outlet header and enters the evaporator through the check

valve assembly. As the hot gas defrosts the coil, heat is removed from the

hot gas and eventually it condenses into a liquid and exits the coil at the

distributor side port. The liquid then flows through the check valve of the

thermostatic expansion valve bypass assembly, around the thermostatic

expansion valve, and into the system liquid line. The liquid refrigerant then

feeds other evaporators on the cooling cycle, evaporates, and returns to the

compressor through their suction lines.

Hot gas line sizes for R-22, R0A and R507

System Capacity

BTU/Hr

Equivalent Discharge Length (Ft.)

25

50

75

100

150

4,000

1/2

1/2

1/2

1/2

1/2

5,000

1/2

1/2

1/2

1/2

1/2

6,000

1/2

1/2

1/2

5/8

5/8

7,000

1/2

1/2

5/8

5/8

5/8

8,000

1/2

5/8

5/8

5/8

5/8

9,000

1/2

5/8

5/8

5/8

5/8

10,000

1/2

5/8

5/8

5/8

5/8

12,000

5/8

5/8

5/8

7/8

7/8

14,000

5/8

5/8

7/8

7/8

7/8

16,000

5/8

5/8

7/8

7/8

7/8

18,000

5/8

7/8

7/8

7/8

7/8

20,000

5/8

7/8

7/8

7/8

7/8

25,000

7/8

7/8

7/8

7/8

1-1/8

30,000

7/8

7/8

7/8

1-1/8

1-1/8

35,000

7/8

7/8

1-1/8

1-1/8

1-1/8

40,000

7/8

1-1/8

1-1/8

1-1/8

1-1/8

45,000

7/8

1-1/8

1-1/8

1-1/8

1-1/8

50,000

7/8

1-1/8

1-1/8

1-1/8

1-1/8

60,000

1-1/8

1-1/8

1-1/8

1-3/8

1-3/8

70,000

1-1/8

1-1/8

1-3/8

1-3/8

1-3/8

80,000

1-1/8

1-1/8

1-3/8

1-3/8

1-5/8

90,000

1-1/8

1-3/8

1-3/8

1-5/8

1-5/8

100,000

1-1/8

1-3/8

1-3/8

1-5/8

1-5/8

Note: Use next larger hot gas line size for -20

0

F. and lower suction temperatures.

EVAP. COIL

TXV

PAN LOOP

THREE-PIPE DEFROST PIPING

CHECK

VALVE

HOT GAS LINE

LIQUID LINE

SUCTION LINE

HEAT – X

EVAP. COIL

TXV

PAN LOOP

CHECK VALVE

REVERSE CYCLE DEFROST PIPING

CHECK VALVE

CHECK

VALVE

LIQUID

LINE

SUCTION

LINE

HEAT – X

IMPORTANT:

It is imperative that with the alternating evaporator hot

gas defrost system, no more that 25% of the operating

refrigeration load be in defrost at any time.

Three Pipe System

The three pipe system (sometimes called re-evap.) uses three pipes: one for

liquid line, one for suction line, and one for hot gas line. In addition, a re-

evaporator accumulator is used at the suction outlet of the evaporator. The

hot gas is taken from the discharge line between the compressor and the

condenser, through a hot gas solenoid valve, then to the evaporator drain

pan circuit, distributor tee, through the coil. See the Three-Pipe Defrost

Piping Diagram for typical piping at the evaporator coil.

Alternating Evaporator System

In the alternating evaporator hot gas defrost system, a third line is taken

off the compressor discharge line as the re-evap system. It is piped with

solenoids at each evaporator, so that hot gas defrost is accomplished on one

or more evaporators while the remaining evaporators continue to function

in a normal manner. The liquid from defrosting evaporators is reintroduced

to the main liquid line and it is necessary that 75% or greater capacity be

retained in the normal refrigeration cycle to offset the capacity that is being

removed by the units on the hot gas defrost.