Heatcraft Refrigeration Products Condensing Units H-IM-CU User Manual

Page 16

1

System Balancing - Compressor Superheat

IMPORTANT:

In order to obtain the maximum capacity from a system, and to ensure

trouble-free operation, it is necessary to balance each and every system.

This is extremely important with any refrigeration system.

The critical value which must be checked is suction superheat.

Suction superheat should be checked at the compressor as follows:

Measure the suction pressure at the suction service valve of the

compressor and determine the saturation temperature corresponding

to this pressure from a “Temperature-Pressure” chart.

Measure the suction temperature of the suction line about one

foot back from the compressor using an accurate thermometer.

Subtract the saturated temperature from the actual

suction line temperature. The difference is superheat.

Too low a suction superheat can result in liquid being returned to the

compressor. This will cause dilution of the oil and eventual failure of the

bearings and rings or in the extreme case, valve failure.

Too high a suction superheat will result in excessive discharge temperatures

which cause a break down of the oil and results in piston ring wear, piston

and cylinder wall damage.

It should also be remembered that the system capacity decreases as the

suction superheat increases. For maximum system capacity, suction

superheat should be kept as low as is practical. Copeland mandates a

minimum superheat of 20˚F at the compressor. We recommend that the

superheat at the compressor be between 20˚F and 30˚F.

If adjustments to the suction superheat need to be made, the expansion

valve at the evaporator should be adjusted.

1.

2.

3.

Operational Check Out

After the system has been charged and has operated for at least two hours at

normal operating conditions without any indication of malfunction, it should

be allowed to operate overnight on automatic controls. Then a thorough

recheck of the entire system operation should be made as follows:

Check compressor discharge and suction pressures.

If not within system design limits, determine why and

take corrective action.

Check liquid line sight glass and expansion valve operation. If

there are indications that more refrigerant is required, leak test

all connections and system components and repair any

leaks before adding refrigerant.

Observe oil level in compressor crankcase sight glass. Add oil as

necessary to bring level to bottom 1/4 of the sight glass.

Thermostatic expansion valves must be checked

for proper superheat settings. Feeler bulbs must be

in positive contact with the suction line and should

be insulated. Valves set at high superheat will lower

refrigeration capacity. Low superheat promotes

liquid slugging and compressor bearing washout.

Using suitable instruments, carefully check line voltage and

amperage at the compressor terminals. Voltage must be within

10% of that indicated on the condensing unit nameplate. If high

or low voltage is indicated, notify the power company.

If amperage draw is excessive, immediately determine the cause

and take corrective action. On three phase motor compressors,

check to see that a balanced load is drawn

by each phase.

The maximum approved settings for high pressure controls on

our air cooled condensing equipment is 425 psig. On air cooled

systems, check as follows:

Disconnect the fan motors or block the condenser inlet air. Watch

high pressure gauge for cutout point. Recheck all safety and

operating controls for proper operation and adjust if necessary.

Check defrost controls for initiation and termination settings, and

length of defrost period. Set fail safe at length of defrost + 25%.

Example:

20 minute defrost + 5 minutes

= 25 minute fail safe

Check drain pan for proper drainage.

Check winter head pressure controls for pressure setting.

Check crankcase heater operation if used.

Install instruction card and control system diagram for

use of building manager or owner.

a)

b)

c)

d)

e)

f)

g)

h)

i)

j)

k)

NOTE:

All adjustable controls and valves must be field adjusted to meet desired

operation. There are no factory preset controls or valve adjustments. This

includes low pressure, high pressure, adjustable head pressure systems

and expansion valves.

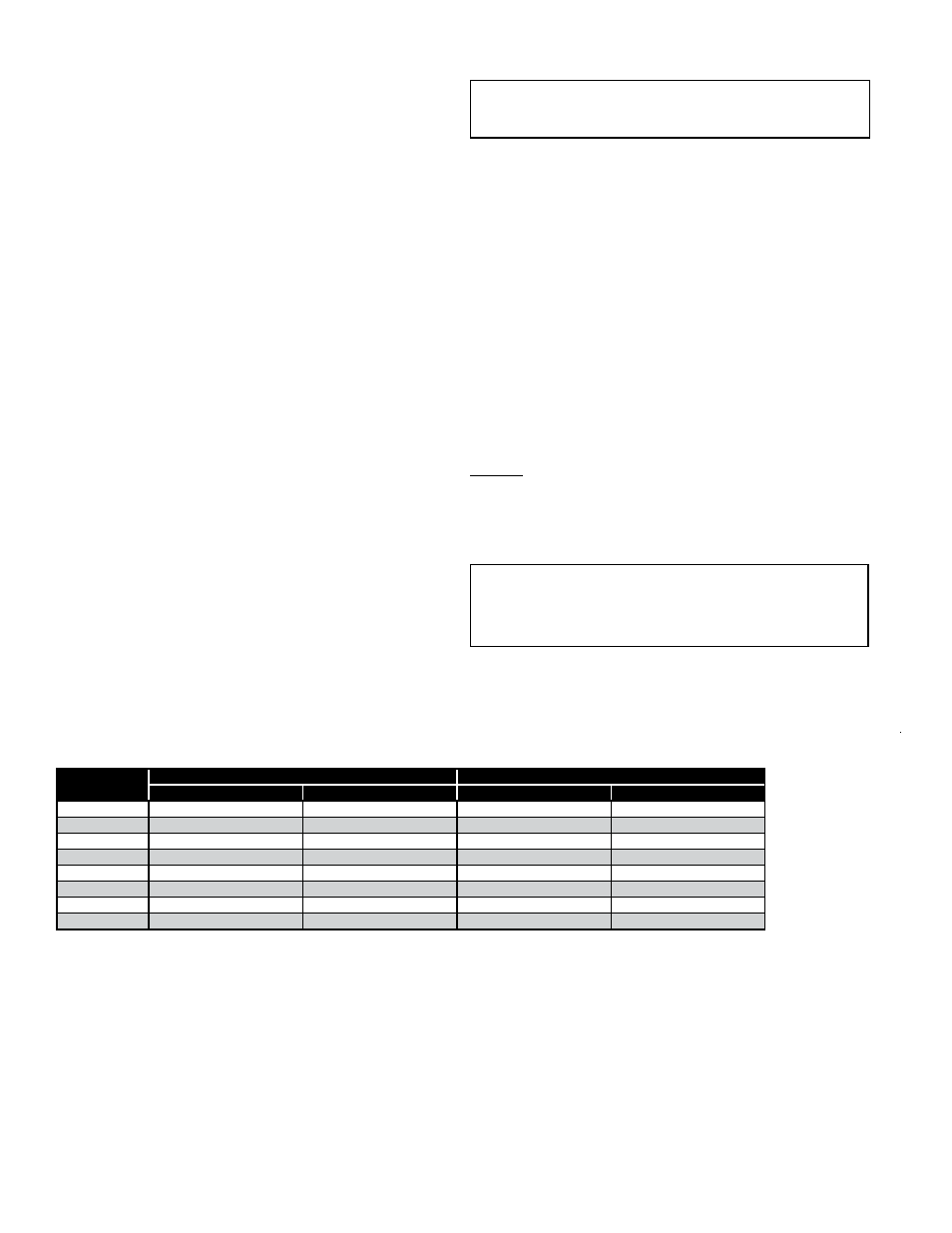

Table 9. Recommended Low Pressure Control Settings for Outdoor Air Cooled Condensing Units

*Minimum

Temp. ˚F

R-22

R-0A/R-507

Cut-In PSI

Cut-Out PSI

Cut-In PSI

Cut-Out PSI

50

70

20

90

35

40

55

20

70

35

30

40

20

55

35

10

30

10

45

25

0

15

0

25

7

-10

15

0

20

1

-20

10

0

12

1

-30

6

0

8

1"Hg.

* Minimum ambient or box temperature anticipated, high pressure control setting: R-22, 360 PSI; R-404A, R-507, 400 PSI

* The standard preset low pressure switch used for pumpdown is set for 15 PSI cut in / 4 PSI cut out and is a good setting for most pumpdown systems

* ZB Scroll compressors should be set for 25 PSI cut in / 17 PSI cut out (R-404A / R-507)