Mounting, Assembly, Safety opera tion maintenance setup – Harbor Freight Tools Central Machinery 13" Bench Drill Press 38142 User Manual

Page 6

Page 6

For technical questions, please call 1-800-444-3353.

Item 38142

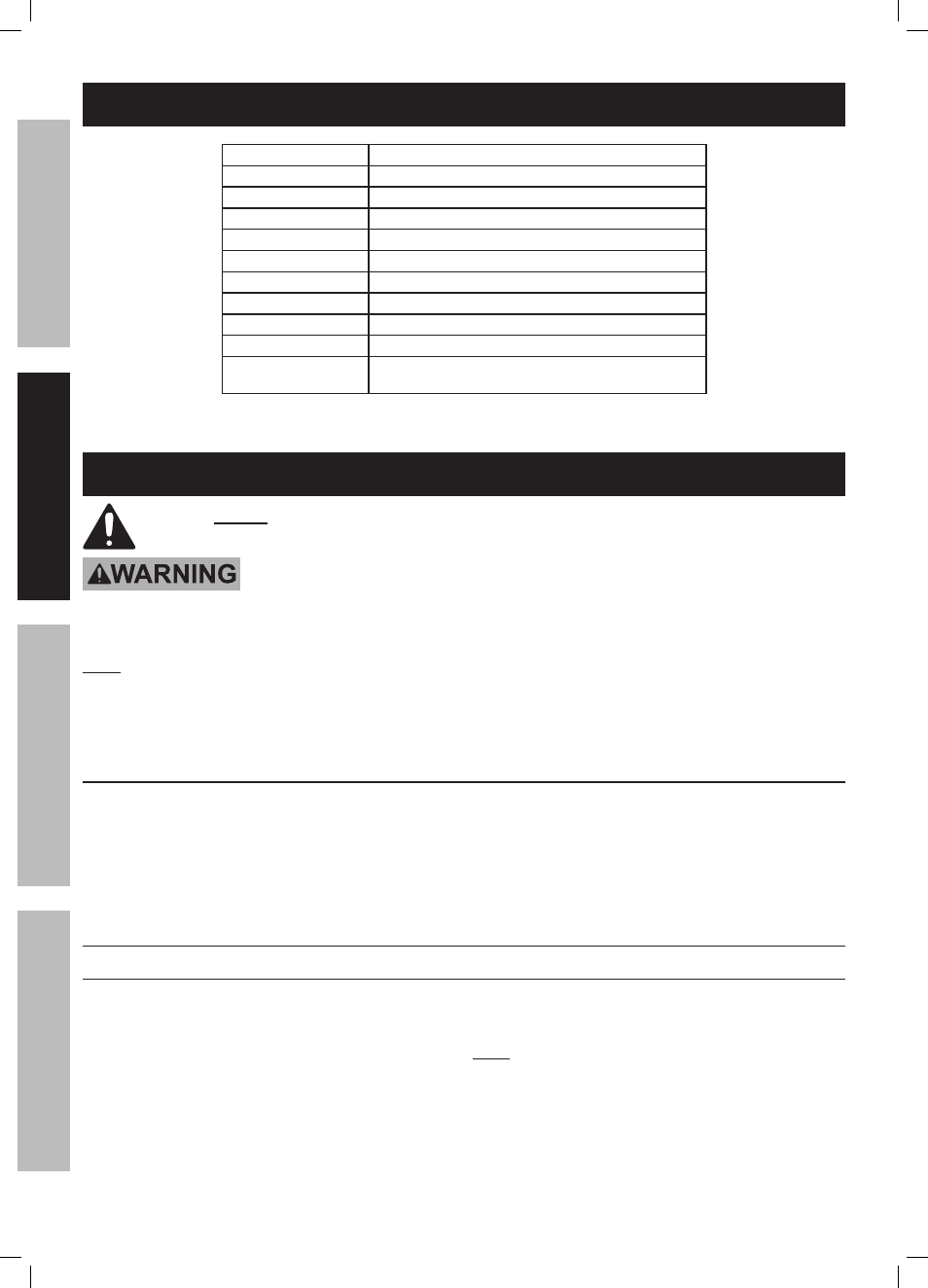

Specifications

Motor Power

3/4 HP - 16 speeds ranging from 220 to 3600 RPM

Electrical Rating

120V~, 60Hz, 7.5A, Single-Phase

Drill Chuck Capacity

7/64″ to 5/8″

Spindle Stroke

3-1/8″

Swing

13-1/4″

Column Diameter

2- 57/64″

Dry Table

11-1/2″ Diameter

Table Slot

1/2″

Overall Height

41-3/4″

Weight

110 lbs.

Product Use

For heavy-duty use on metal, plastic or wood materials.

Table rotates 360º and tilts 0-45º in 1º increments.

Setup - Before Use:

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this

manual including all text under subheadings therein before set up or use of this product.

TO PREVENT SERIOUS INJURY FROM ACCIDENTAL OPERATION:

Turn the Power Switch of the tool off and unplug the tool from its electrical

outlet before performing any procedure in this section.

Note: For additional information regarding the parts listed in the following pages,

refer to the Assembly Diagram near the end of this manual.

Mounting

Secure the tool to a supporting structure before use.

Before assembly, bolt the Base to a flat, level,

solid workbench capable of supporting the

weight of the drill press and any workpieces.

Verify that installation surface has no hidden

utility lines before drilling or driving screws.

Assembly

Column Assembly to Base

1. With the Base (6B) on a flat level surface,

bolt on the Column Support (4B) using the

four M10x40mm Hex Head screws (5B).

2. Tighten firmly.

3. Insert the Column (1B) into its Support (4B) and

firmly secure with the Hex socket set screws (3B).

Note: It may be necessary to screw out the set

screws beforehand, as they may protrude into the

tube preventing the column from sliding in fully.

SAFETY

OPERA

TION

MAINTENANCE

SETUP