7. electrode movement during welding, 8. butt joints – Hobart Welding Products STICKMATE OM-949 User Manual

Page 27

OM-949 Page 23

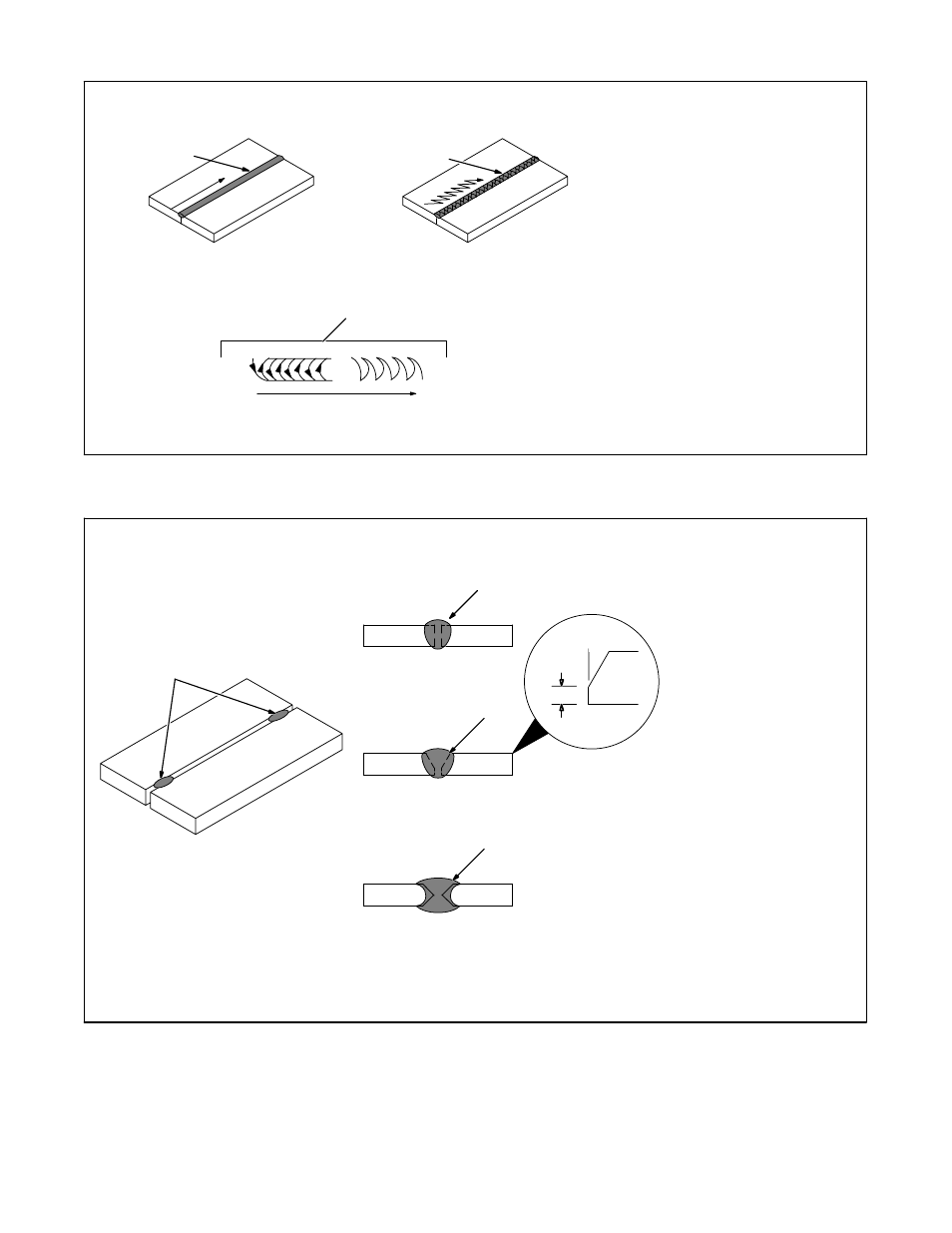

7-7. Electrode Movement During Welding

S-0054-A

1

Stringer Bead − Steady Move-

ment Along Seam

2

Weave Bead − Side To Side

Movement Along Seam

3

Weave Patterns

Use weave patterns to cover a wide

area in one pass of the electrode.

Do not let weave width exceed

2-1/2 times diameter of electrode.

.

A single stringer bead is

satisfactory for most narrow

groove weld joints. For wide

groove weld joints or bridging

across gaps, a weave bead

works better.

1

2

3

7-8. Butt Joints

S-0662

1

Tack Welds

Prevent edges of joint from drawing

together ahead of electrode by tack

welding the materials in position be-

fore final weld.

2

Square Groove Weld

Good for materials up to 3/16 in (5

mm) thick.

3

Single V-Groove Weld

Good for materials 3/16 through 3/4

in (5-19 mm) thick. Cut bevel with

oxyacetylene or plasma cutting

equipment. Remove scale from

material after cutting. A grinder can

also be used to prepare bevels.

Create 30 degree angle of bevel on

materials in V-groove welding.

4

Double V-Groove Weld

Good for materials thicker than 3/16

in (5 mm).

30

°

2

3

4

1

1/16 in

(1.6 mm)