Before you start – Huffy 211972B User Manual

Page 5

5

06/03

P/N 211972B

INSTRUCTIONS

IMPORTANT! WRITE MODEL NUMBER FROM BOX ONTO PAGE 1 OF THIS

OWNERS MANUAL

1.

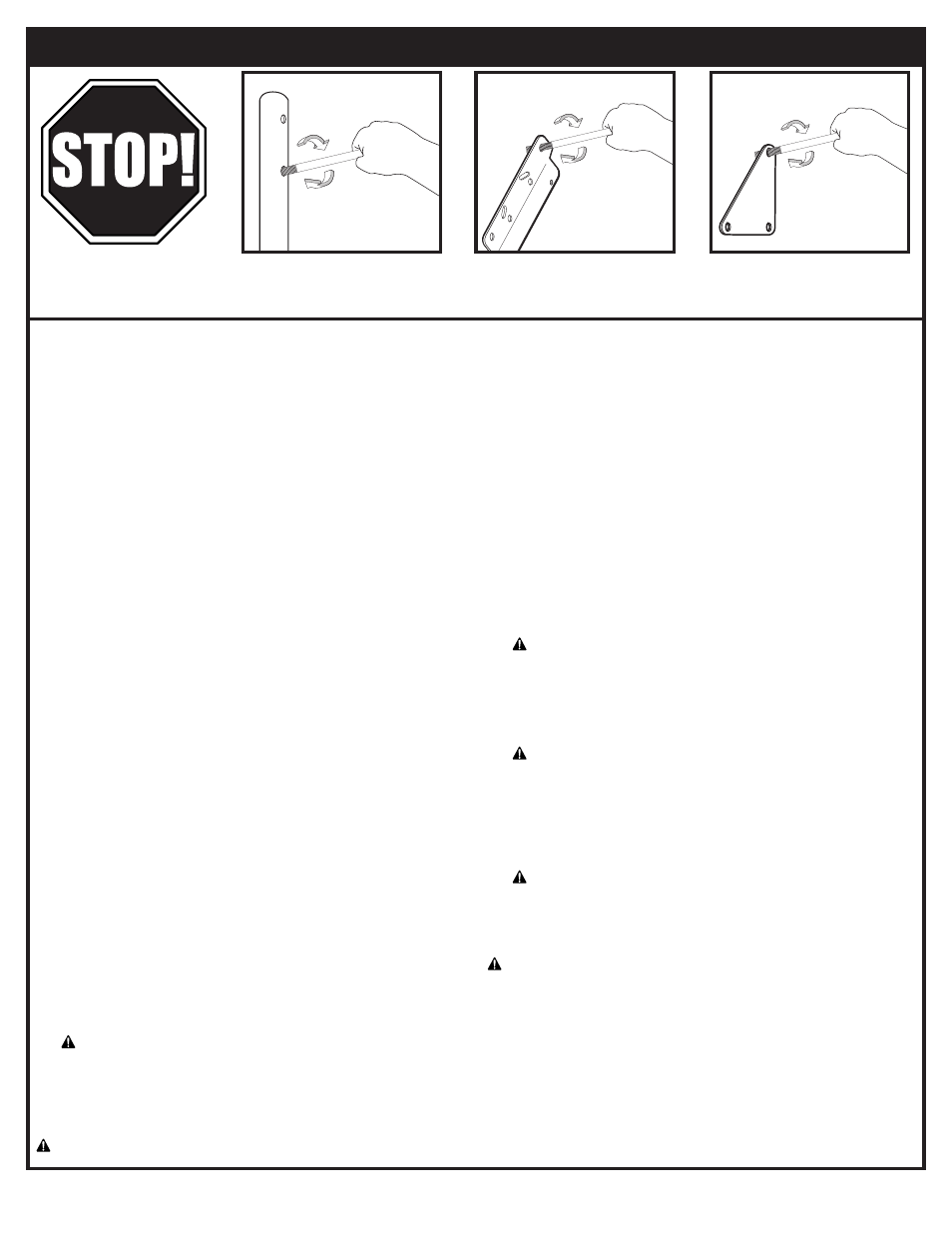

Mark pole sections with tape as shown.

2.

IMPORTANT! Bounce pole top (1) and middle section (2) together as

shown until they no longer move toward taped reference mark.

Upright assembly. NOTE: Pole sections should have a 3-1/2" (9 cm)

minimum overlap.

3.

IMPORTANT! Holes in top (1) and bottom pole (3) sections MUST

align to correctly position elevator system toward playing surface.

Add bottom pole section (3) to assembly as shown and bounce until

completely tight. NOTE: Pole sections should have a 3-1/2" (9 cm)

minimum overlap.

4.

Install wheels (17) onto axle (28) and wheel bracket (25) with push caps

(29) as shown.

5.

Position base as shown. Secure wheel bracket assembly with bolt (16) and

nut (15) as shown.

6.

Install rod (4) through holes in bottom pole section (3) and eyebolt (5).

Insert pole assembly into tank (6) and through center hole on wheel

assembly as shown.

Secure pole assembly with strap (61), washer (11)

and lock nut (8).

7.

Secure base struts (9) to pole using bolt (10) washers (11) and nut (12) as

shown. Rotate the non-secured ends of base struts (9) as shown.

8.

Secure base struts (9) to base using bolt (14) washers (11) and nut (15).

9.

Install upper pivot bracket (18) to front of base using bolt (19), washer (20)

and nut (8) as shown.

10. Insert bolt (21) through lower pivot bracket (22) as shown, bolt (21) will be

secured during step 12. Carefully place base assembly on its side. Install

lower pivot bracket (22) with bolt (23), washers (20) and lock nut (8) as

shown.

11. Secure both hinge tubes (24) to second wheel bracket (25) with carriage

bolts (26) and flange nuts (15).

12. Install wheels (27) onto axle (28) and wheel bracket (25) with push caps

(29) as shown.

13. Position base as shown. Secure wheel bracket assembly with disc (30),

washer (20) and nut (8) as shown. NOTE: Two people recommended for

this step.

14. Carefully reposition entire assembly as shown. IMPORTANT! Two people

recommended for this step.

15. Snap tinnerman nut (31) onto inner channel (32). Place inner channel into

outer channel (33) as shown.

16. Slide handle (34) into position as shown and secure with bolts (35),

washers (11), and nuts (15). Tighten completely.

17. Install bolt (36), washers (11), and nut (37) as shown. Tighten until

washers (11) are no longer loose. NOTE: Do not over tighten. Assemble

trigger (38) to handle assembly (34, 32, 31) as shown and secure with bolt

(39) and washer (11). Tighten completely.

18.

WARNING: USE EYE PROTECTION WHEN INSTALLING SPRINGS.

Install trigger return spring (40) to handle assembly (32, 33) as shown.

19. Attach Accuheight label (41) to inner channel (32).

20. Attach spring (44) to pins (43) and install pins (43) onto pole mount bracket

(45). Attach other spring (44) to opposite side. NOTE: Gently enlarge

eyelets of spring with pliers if springs do not fit over pins.

WARNING: USE EYE PROTECTION WHEN INSTALLING SPRINGS.

21. Install pole mount assembly and reinforcement bracket (47) with carriage

bolts (46) to pole as shown. Tighten flange nuts (15) completely.

22. Push back sliding pin (43) as shown in Figure A to fit adjustable system

assembly through pole mount assembly. Then attach spring covers (48 &

49) onto pole mount bracket (45) with bolt (50), and nut (15) as shown in

Figure B.

23. Attach backboard support brackets (52) to the backboard frame using bolts

(53), spacers (51), and nuts (37) as shown.

24. Attach lower elevator tubes (56) and spring (68) to backboard support

brackets (52) using spacers (59), bolt (57), and nut (58) as shown. NOTE:

Rim mounting nuts and bolts (60) supplied with rim hardware.

25. Attach upper elevator tubes (63) to backboard support brackets (52) using

spacers (59), bolt (57), and nut (58) as shown.

26. Support pole on sawhorse. Attach backboard assembly to top pole section

(1) as shown. Then install pole cap (64). NOTE: Two people are

recommended for this step. Use caution; elevator assembly is heavy.

27. Install upper elevator tubes (63) to triangle plates (66) as shown.

Install handle assembly to lower elevator tubes (56) using bolt (57),

spacers (67), and nut (58) as shown. NOTE: Tighten bolt (57) in lock nut

(58) until flush (even) with lock nut’s outer edge. NOTE: Before going on

to next step, set adjustable system assembly to the 10’ (3.05 m) setting.

28.

WARNING: USE EYE PROTECTION WHEN INSTALLING SPRINGS.

Insert bolt (57) through left side upper elevator tube (63), then stretch

springs (68) onto bolt (57). Insert bolt (57) through right side upper

elevator tube (63) and secure with nut (58).

29. Attach front cover (54) to hinge tubes (24) using carriage bolt (42) and

flange

nuts (15) as shown.

30.

WARNING: DO NOT LEAVE ASSEMBLY UNATTENDED WHEN

EMPTY, MAY TIP OVER.

Apply height and moving label (76) to front of pole as shown.

31. Roll completed assembly to desired playing area. Secure assembly to

ground using strap (61) and tie down stake (7). Fill tank with 34 gallons of

water. IMPORTANT! Add two gallons (7.6 Liters) of non-toxic

antifreeze in sub-freezing climates. Add two gallons (7.6 liters) to tank

to prevent freezing in sub-freezing climates. Snap cap (62) into place.

WARNING: DO NOT ALLOW CHILDREN TO ADJUST HEIGHT.

32. Grasp handle and depress lever.

33. Push toward pole while holding lever. Raise or lower lever to desired

height while pushing forward on handle.

34. Release handle making sure that horizontal pin (43) is locked into slot.

WARNING: USE OF THIS PRODUCT WITHOUT PROPER

INSTALLATION OF SMART CLIPS, OR WHEN ALL SMART CLIPS ARE

NOT PRESENT COULD RESULT IN BODILY HARM. BE SURE TO

FOLLOW DIRECTIONS CAREFULLY.

35. Install net clips as shown. (See illustration)

36. Install net as shown. (See illustration)

BEFORE YOU START!

To ensure optimal playability of backboard system, a close tolerance fit between the elevator components and

hardware is required. Test fit large bolts into large holes of elevator tubes, backboard brackets and triangle plates.

Carefully rock them in a circular motion to ream out any excess paint from holes if necessary.