A comparison: conventional versus hvlp spray guns, Preparation – Harbor Freight Tools 30224 User Manual

Page 7

For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

SKU 30224

Page 7

Preparation

Note: Proper paint material mixture helps to ensure less problems. Be sure to follow the

manufacturer’s directions. Most materials will spray readily if they are thinned properly.

General tips for Preparation:

1.

Mix and thin the paint/materials thoroughly according to the manufacturer’s directions.

2.

Carefully strain the paint/material through a paint strainer or piece of cheese cloth.

3.

Swing the Cup Locking Lever (44) out of the locked position to remove the Cup (47)

from the Unit. Fill the Cup (47) to approximately 3/4 full. Place the Cup (47) back on

the unit and swing the Cup Locking Lever (44) to the locked position.

4.

Start the air compressor.

5.

To adjust the spray pattern, set up a piece of scrap material to practice on. While

practicing on the scrap material, check to see that the material you are spraying has

the appropriate consistency. If it appears to thin, add a very small amount of thinner

(not included). BE CAREFUL when thinning. Proceed slowly, adding very minimal

amounts. NEVER exceed the manufacturer’s thinning recommendations.

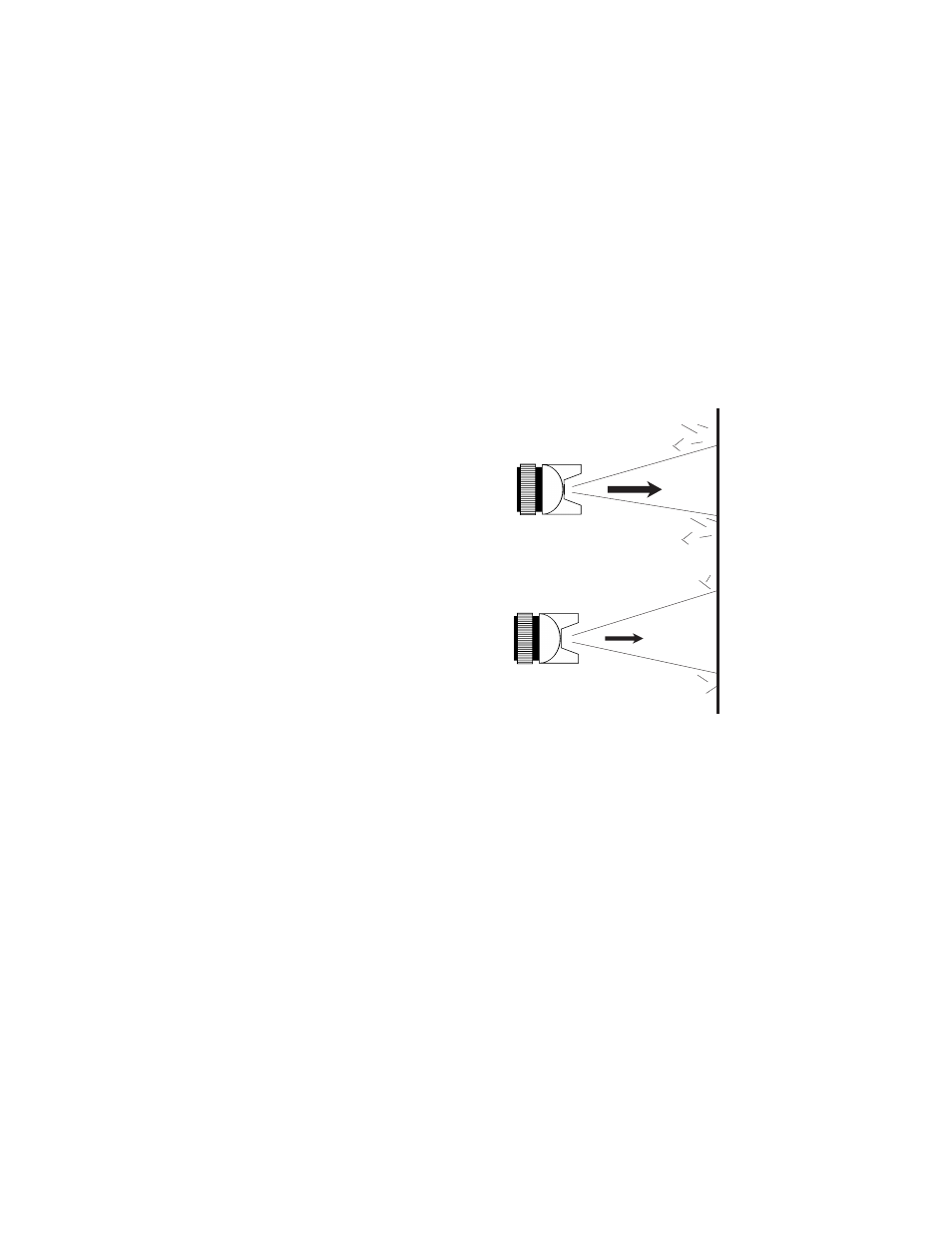

A Comparison: Conventional versus HVLP Spray Guns

Because conventional spray guns require a much higher air cap pressure to atomize

the paint than HVLP Spray Guns, conventional guns have lower transfer efficiencies

and more overspray.

This translates to a significant paint/material savings for HVLP guns, in addition to

making them more environmentally friendly.

To qualify as HVLP, the dynamic air pressure going in the Air Cap must be a maximum

of 10 PSI. The lower the air pressure, the less bounce back and overspray.

See FIGURE 2 below.

Conventional

HVLP

FIGURE 2