Pump drive belt tension, Deck belt tension, Adjusting the parking brake – Exmark Pioneer S-Series 0 User Manual

Page 37: Maintenance

Maintenance

each side of the cutting deck. Place two “A” thick

blocks (see Block Height and Rake Table in Deck

Leveling) under each side of the front edge of the

deck, but not under the anti-scalp roller brackets.

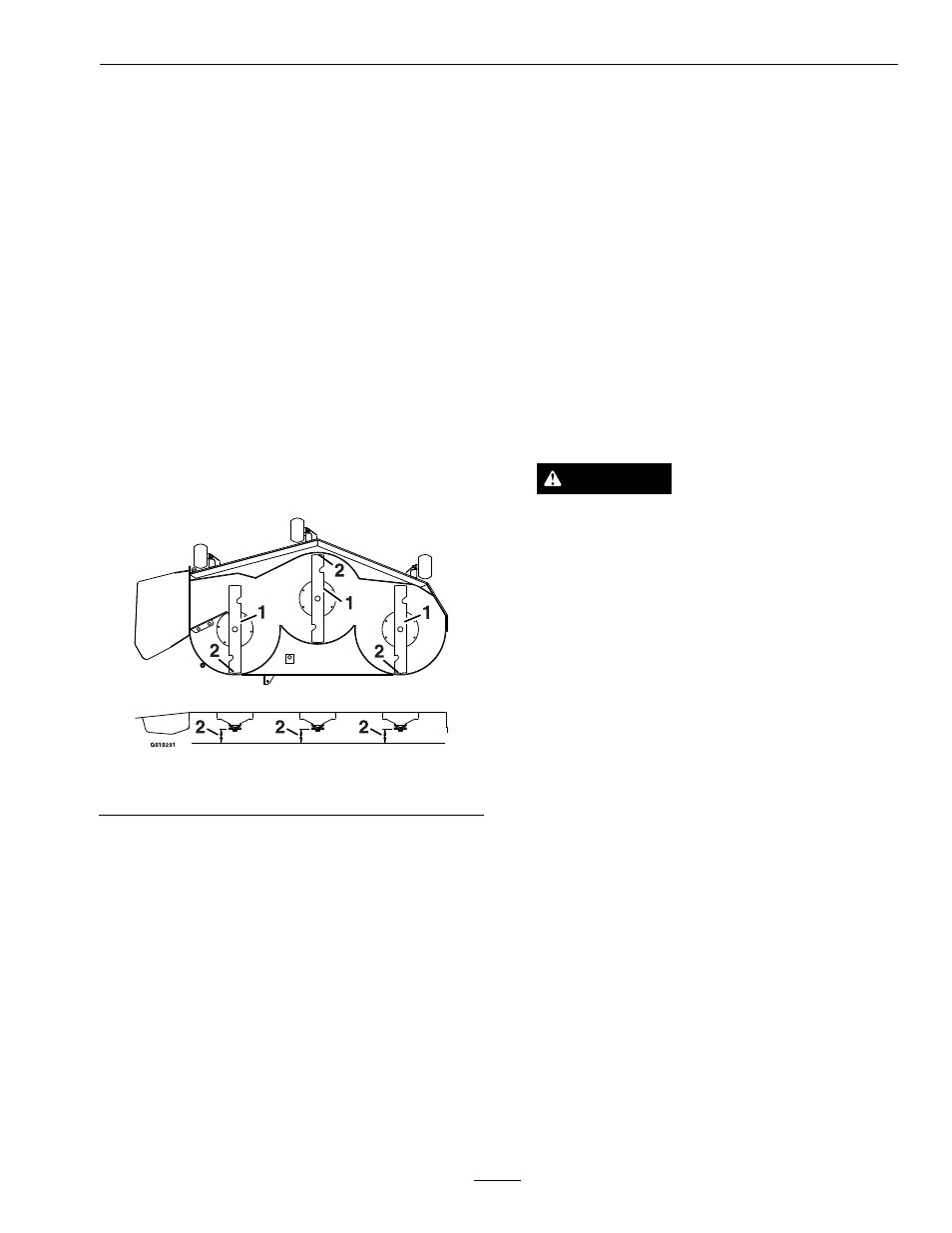

7. Loosen the leveling adjust locking nuts (item 1

Figure 27) on all four corners so that the deck is

sitting securely on all four blocks. Make sure that

the slack is removed from the deck hangers and

the deck lift foot lever is pushed back against the

stop, then tighten the four leveling adjust locking

nuts.

8. Carefully rotate the blades so they are facing front

to rear (Figure 28).

9. Measure from the tip of the front blade to the flat

surface and the tip of the rear blade to the flat

surface (Figure 28). If the front blade tip is not

“R” (see Block Height and Rake Table in Deck

Leveling) lower than the rear blade tip, adjust the

front deck hanger.

Figure 28

1.

Blades front to rear

2.

Measure here

10. When the front-to-rear blade slope is correct

check the side-to-side level of the mower again;

refer to Deck Leveling.

Pump Drive Belt Tension

Self-tensioning - No adjustment necessary.

Deck Belt Tension

Self-tensioning - No adjustment necessary.

Adjusting the Parking Brake

Service Interval: Every 500 hours

Check to make sure brake is adjusted properly. This

procedure must be followed after the first 100 hours

or when a brake component has been removed or

replaced.

1. Drive the machine onto a level surface.

2. Disengage the blade control switch (PTO), move

the motion control levers to the neutral locked

position and set the parking brake.

3. Stop the engine, wait for all moving parts to stop,

and remove the key.

4. Setup the machine to be pushed by hand (see

Drive Wheel Release Valves in the Operation

section).

5. Raise the back of the machine up and support the

machine with jack stands.

CAUTION

Raising the mower deck for service or

maintenance relying solely on mechanical

or hydraulic jacks could be dangerous. The

mechanical or hydraulic jacks may not be

enough support or may malfunction allowing

the unit to fall, which could cause injury.

Do Not rely solely on mechanical or hydraulic

jacks for support. Use adequate jack stands

or equivalent support.

6. Engage/disengage the brake and check each drive

tire to make sure each brake engages/disengages.

7. If adjustment is necessary, loosen the jam nut

from the yoke on the side that needs adjustment.

Remove the hairpin and clevis pin (see Figure 29).

37